Chain Knife Shredder with Single Cut Longitudinal Shredder

A single-cut, shredder technology, applied in grain processing, etc., can solve the problems of short service life, complicated process, inconvenient paper separation, etc., and achieve the effect of long service life, stable structure, and not easy to jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

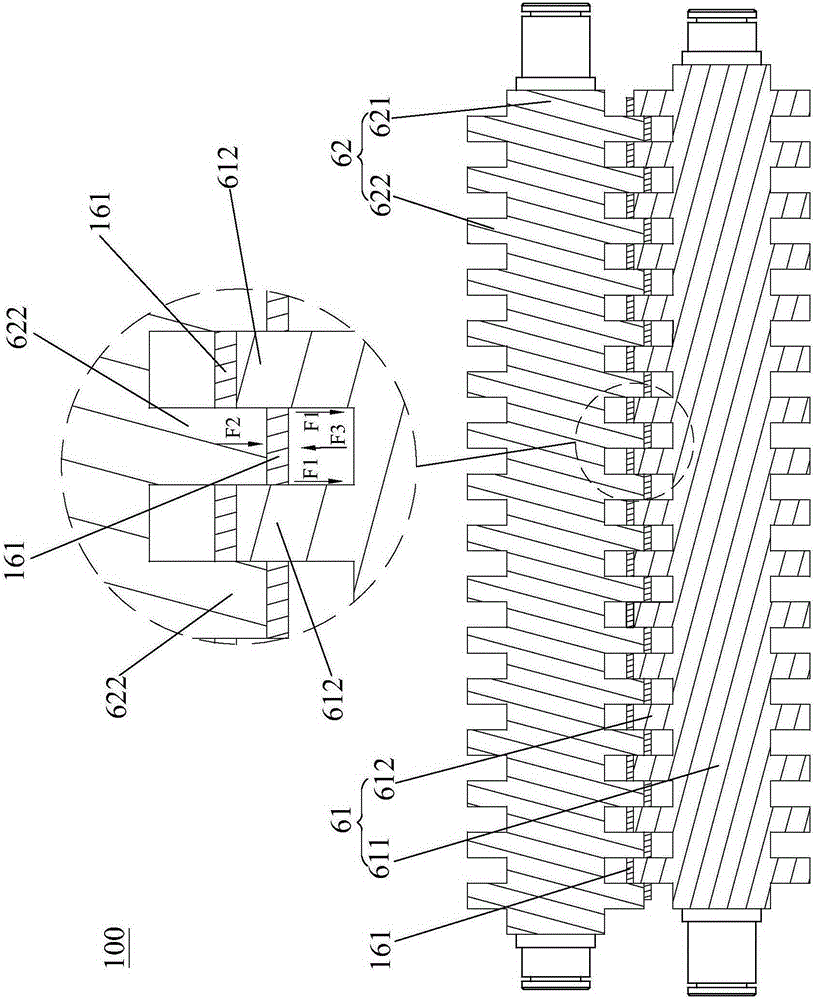

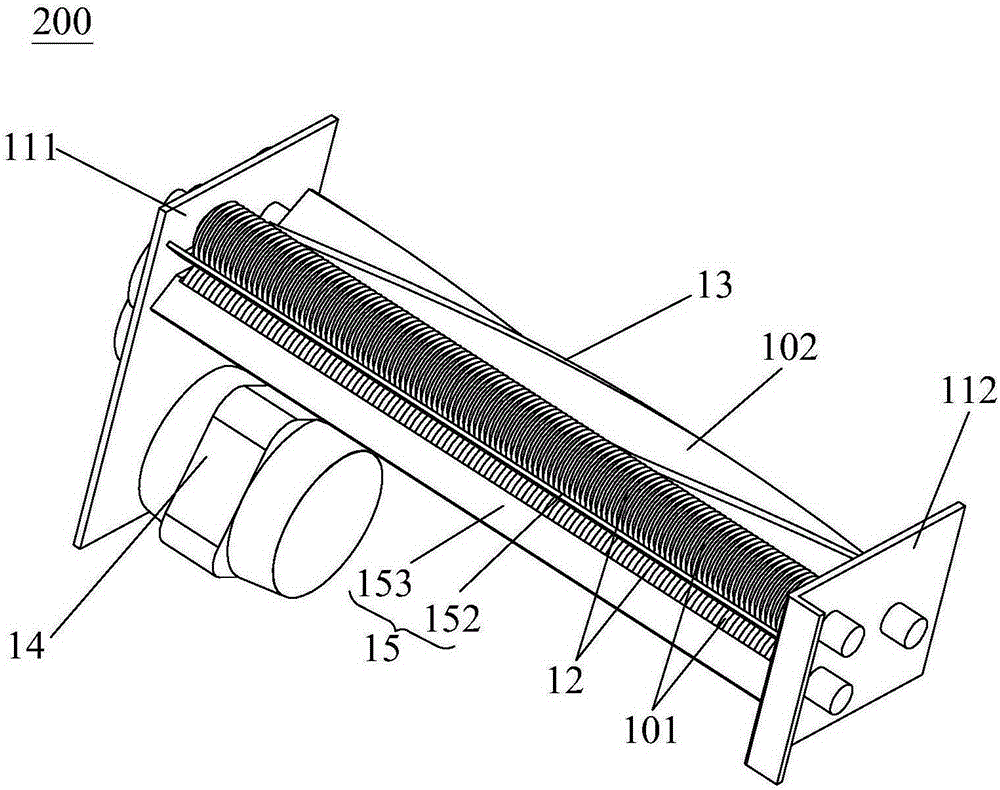

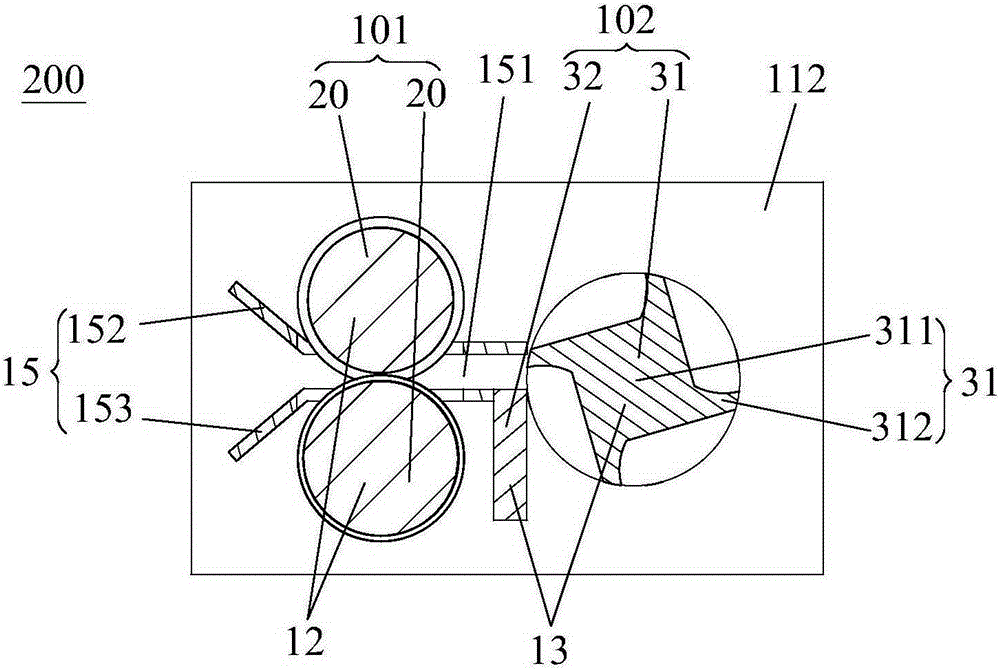

[0045] refer to Figure 2a to Figure 2c , is the first embodiment of the present invention. In this embodiment, the chain knife shredder 200 includes a frame 11 and a first shredder mechanism 12 and a second shredder mechanism installed on the frame 11. 13 and a driving mechanism 14, the driving mechanism 14 is respectively connected with the first shredding mechanism 12 and the second shredding mechanism 13 and drives the first shredding mechanism 12 and the second shredding mechanism 13 to shred paper, and The shredding channel of the first shredding mechanism 12 communicates with the shredding channel of the second shredding mechanism 13 and cuts paper sequentially. In this embodiment, the first shredding mechanism 12 is a single-cut v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com