A spiral homogenizing device for a vertical feeding system of a shredding machine

A technology of feeding system and homogenizing device, which is applied in the application and processing of tobacco and tobacco, can solve the problems such as the inability to effectively guarantee the amount of puffed stalks, the excessive difference in the density of puffed stalks, and the inability to solve the quality of shredding. Simple structure, uniform material density, and the effect of ensuring the quality of shredding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

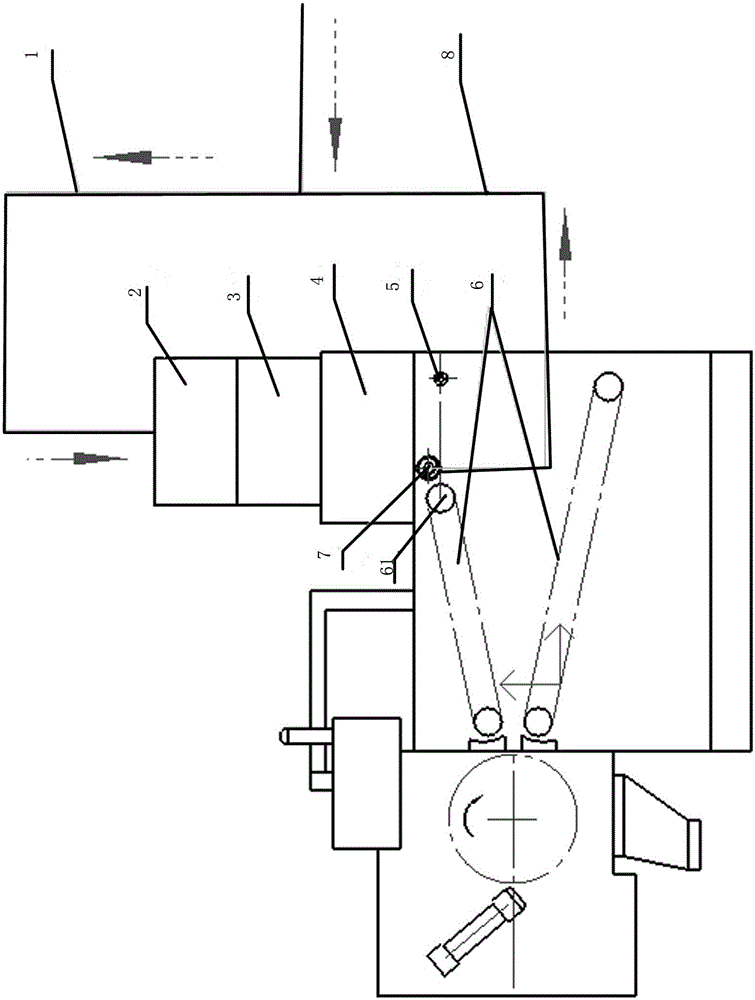

[0015] The vertical feeding system in the original vertical feeding shredder is mainly composed of three parts: the material distribution device 4, the material guide device 3 and the material pushing device 4.

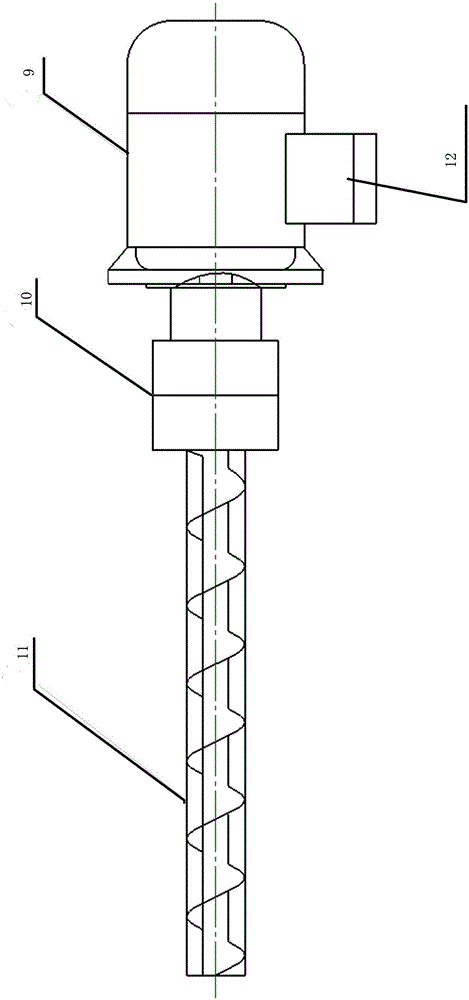

[0016] The screw homogenizing device on the vertical feeding system of the shredder is mainly composed of a screw propulsion device 7, a material level sensor 5, a feed conveyor belt 1 and a material reverse mixing conveyor belt 8, and the screw propulsion device 7 mainly includes a motor 9. The coupling 10 and the screw propulsion rod 11 are sequentially connected to form, and the screw conveyor sold in the market can also be directly selected. At the position of the upper chain drive roller 61, and the lowest point of the front end of the screw propulsion rod 11 is on the same level as the center line of the upper chain drive roller 61, and this plane is used as the material height detection point of the material level sensor 5.

[0017] When working, the material f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com