Method for heating and adjusting temperature of plant heat collector in winter

A heat collecting shed and plant technology is applied in the field of using biomass fuel to heat and adjust the temperature of a plant heat collecting shed in winter, which can solve the problems of low heat recovery rate, severe pollution, energy waste, etc. Significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

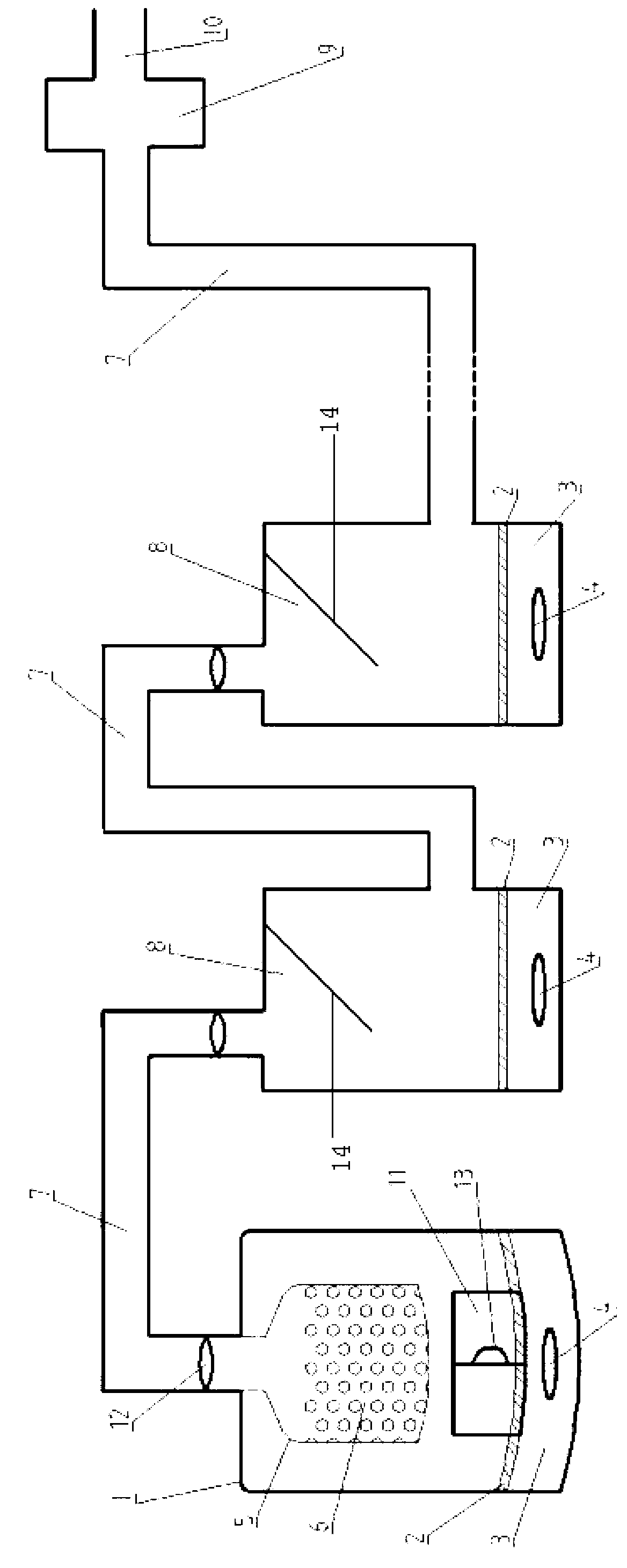

[0015] In this example, the biomass fuel combustion heat collection device is used to produce heat, and the plant planting heat collection shed is heated and adjusted in winter, and the solar heat collection is used to realize the heating and temperature adjustment effect of the heat collection shed. The specific process includes the construction of the heat collection shed , Installation of combustion heat collection device, collection and treatment of fuel, combustion and temperature adjustment and dust collection treatment and utilization in five steps:

[0016] (1) Construction of the heat collection shed: First, process and build the heat collection shed frame according to the existing vegetable heat collection shed structure, and set the heat collection shed section according to the length and width of 2-3:1 in the east-west direction. The north side of the frame is piled up with stones, bricks or mud blocks to form a 1-2 meter high windbreak wall in the east-west directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com