Actuator and camera module comprising same

An actuator and moving frame technology, applied in the imaging field, can solve the problems of increasing the size of the camera module, difficult to meet the requirements of lightness, thinness, and difficult to assemble, and achieve the effects of easy assembly, high assembly efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

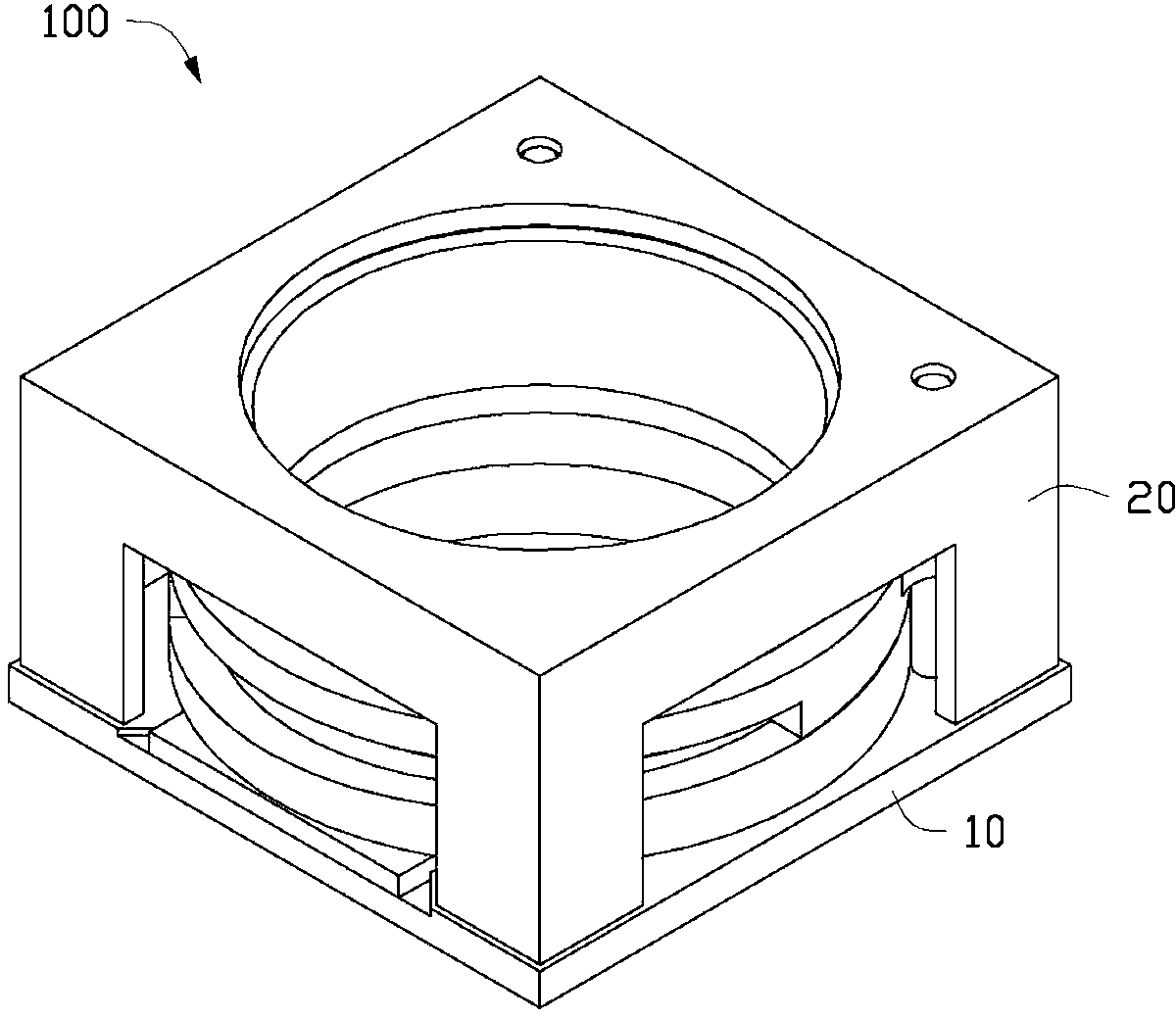

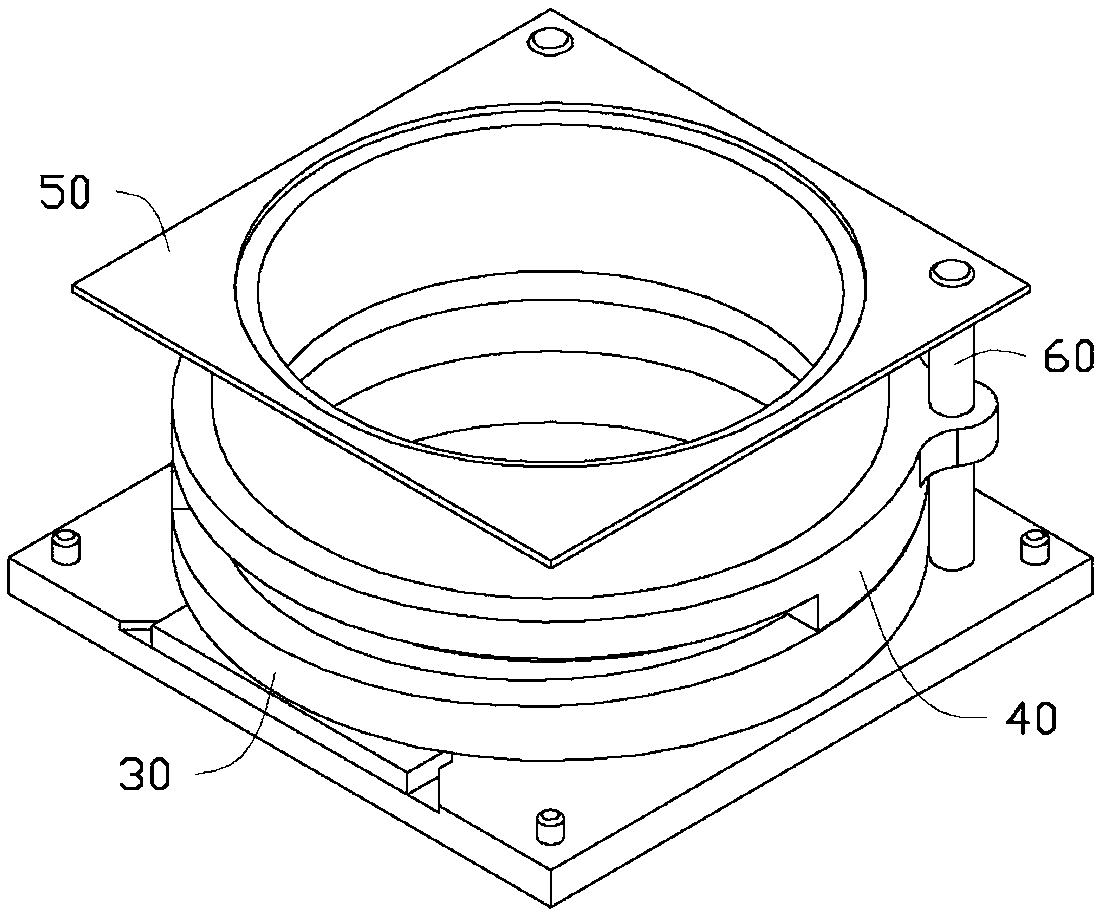

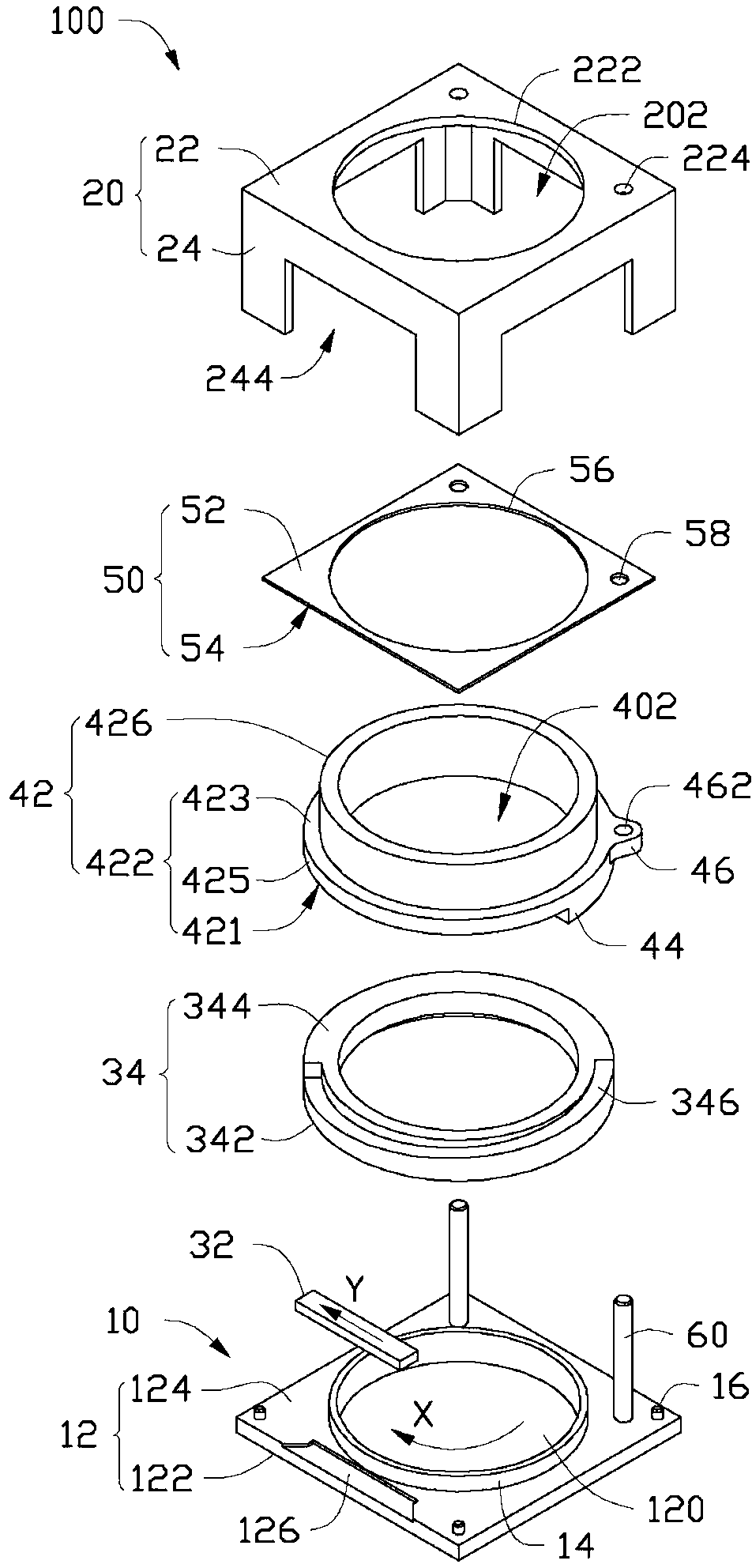

[0017] Please also refer to figure 1 and figure 2 , is the actuator 100 according to the first embodiment of the present invention. The actuator 100 includes a base 10 , a fixed frame 20 , a driving device 30 , a movable frame 40 , an elastic piece 50 , and two guide rods 60 .

[0018] Please also refer to image 3 and Figure 4 , the base 10 includes a flat plate 12 , an annular protrusion 14 , and four engaging posts 16 . The flat panel 12 includes a bottom surface 122 and a top surface 124 opposite to the bottom surface 122 . A circular light hole 120 is defined at the center of the plate 12 , and the light hole 120 passes through the bottom surface 122 and the top surface 124 . A receiving groove 126 is defined on one side of the top surface 124 , and the receiving groove 126 is adjacent to but not connected to the light hole 120 . The annular protrusion 14 extends from the top surface 124 and surrounds the light hole 120 . A part of the annular protrusion 14 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com