Water permeable brick

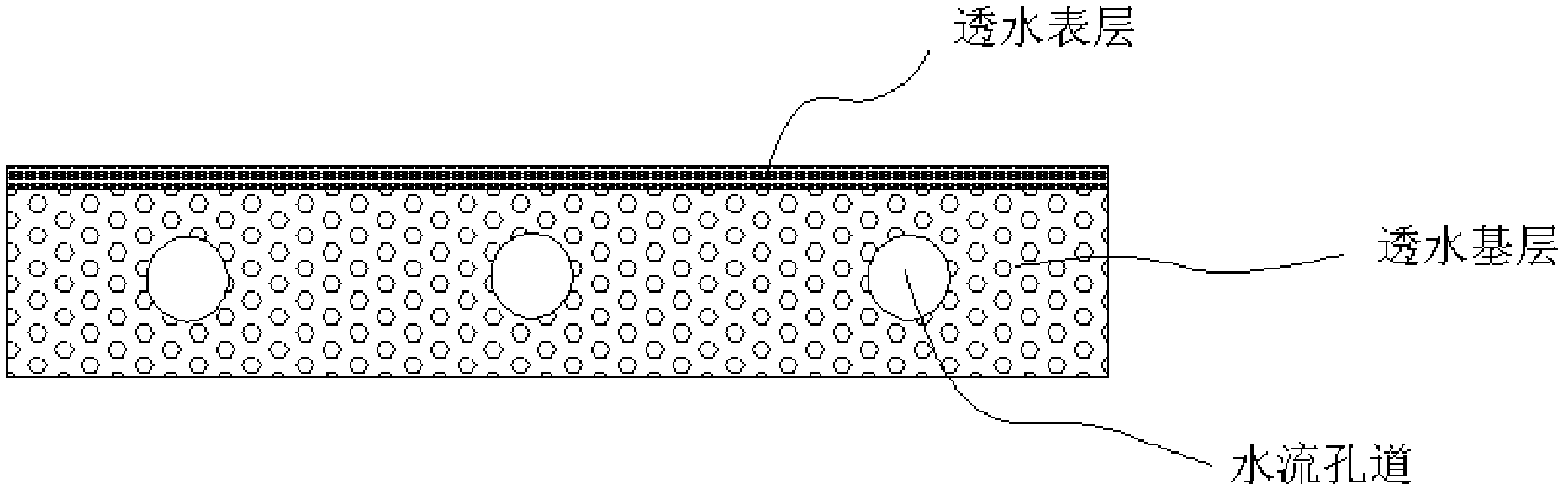

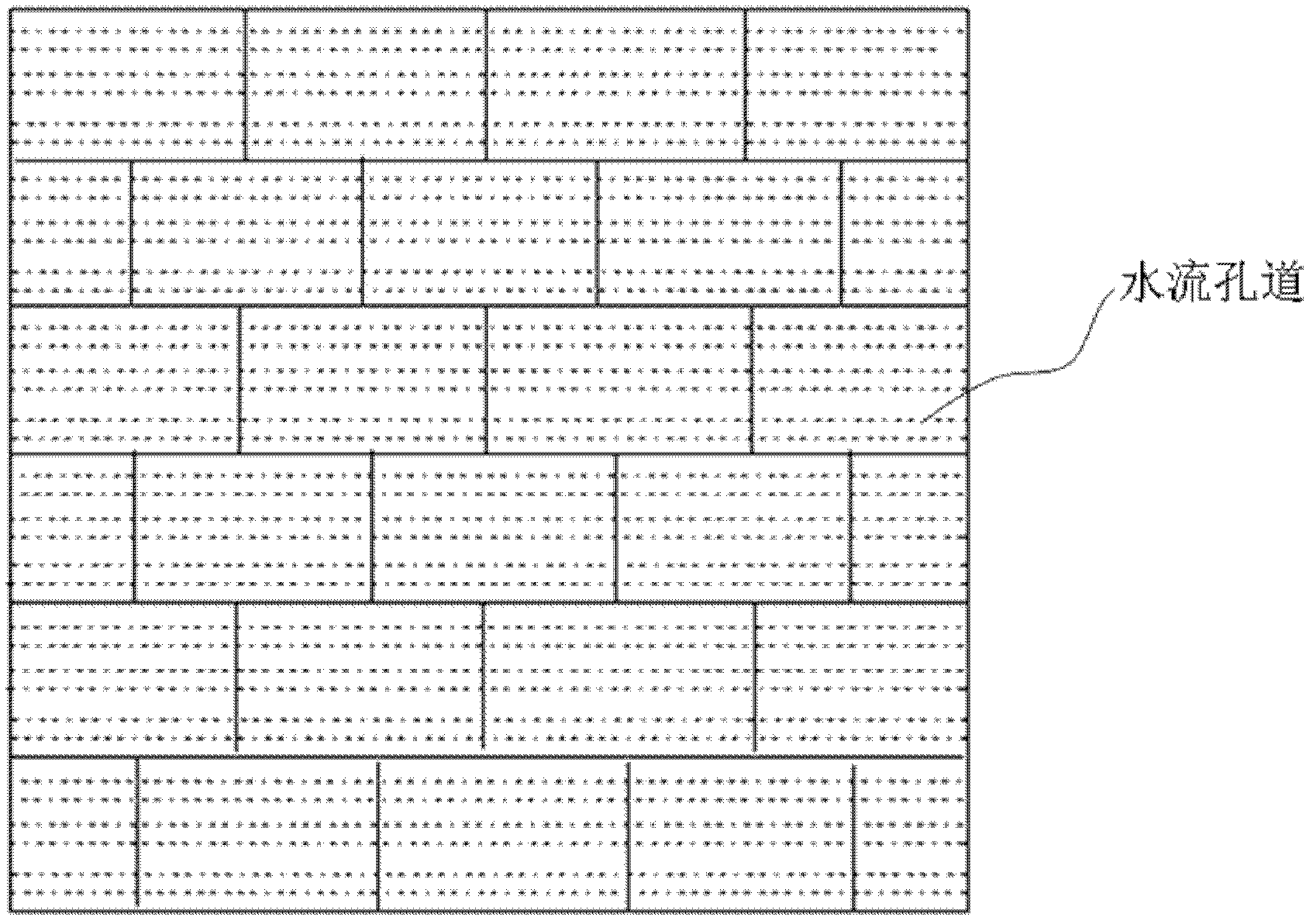

A permeable brick and permeable base technology, which is applied to roads, pavements paved with prefabricated blocks, road surfaces, etc., can solve problems such as loose foundations, and achieve the effects of prolonging service life, excellent drainage capacity, and enhancing water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

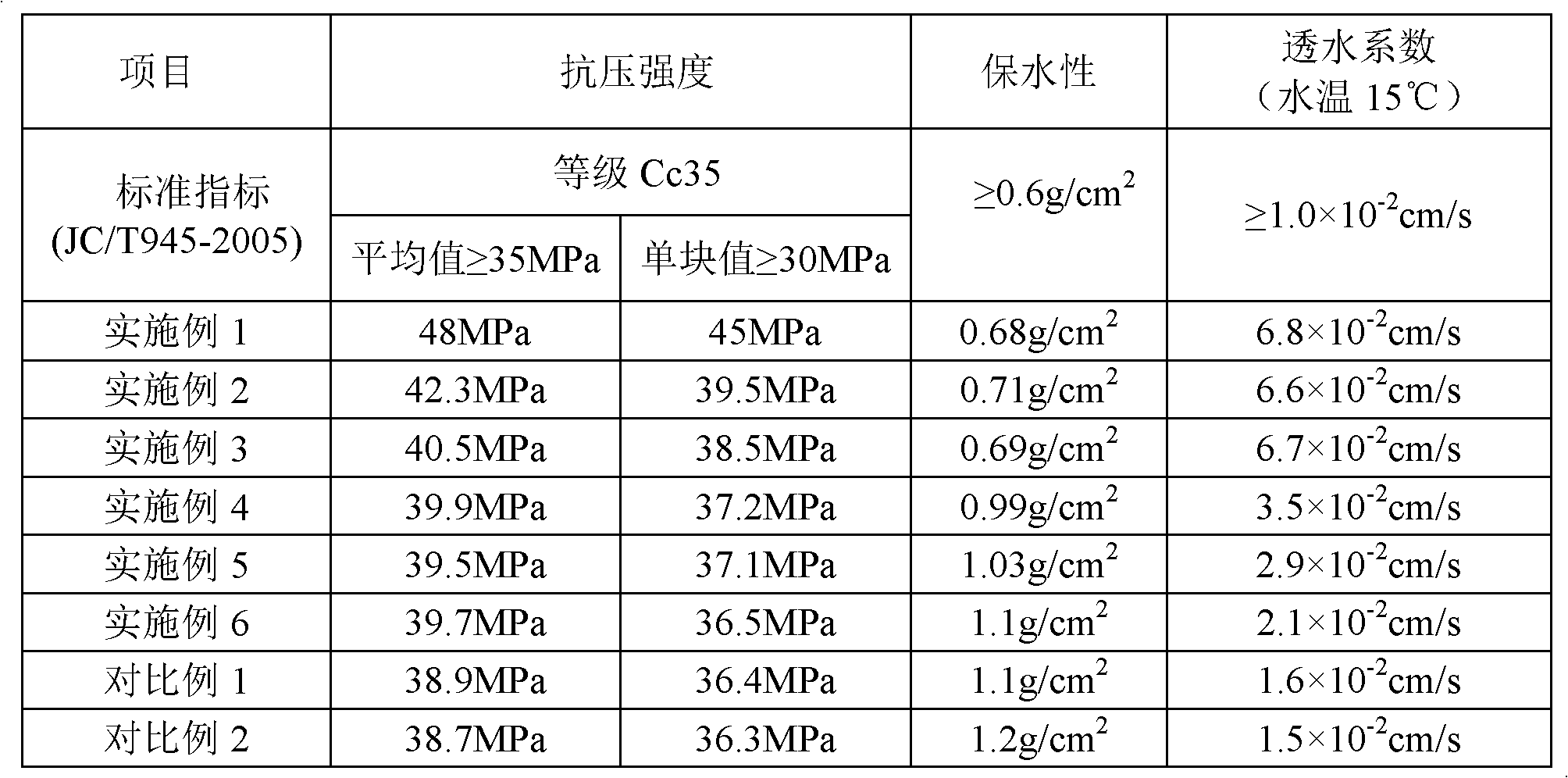

Embodiment 1

[0046] This embodiment is used to illustrate the permeable brick provided by the present invention and its preparation.

[0047] (1) Formation of the second aggregate particles:

[0048] Put 10kg of quartz sand into the muffle furnace, bake it at 300°C for 10 minutes, then transfer the baked quartz sand to the sand mixer, and add 0.04 kg of E-44 water-based epoxy resin, 0.01 kg of phthalocyanine blue (purchased from Dainichi Seika Chemical Co., Ltd., 4920 type), continue to stir, and when the temperature drops to 130 ° C, add 0.005 kg of diethylene triethylene to the mixture amine, and stirred for 60 s to obtain coated quartz sand, the average particle diameter of which was measured by a digital stereo microscope (purchased from Beijing Huaqi Information Digital Technology Co., Ltd., brand DLC300) to be 0.1 mm.

[0049] (2) Formation of permeable bricks:

[0050] 1000g perlite (purchased from Xinyuan bentonite factory in Xinyang Industrial City, with an average particle diam...

Embodiment 2

[0052] This embodiment is used to illustrate the permeable brick provided by the present invention and its preparation.

[0053] (1) Formation of the second aggregate particles:

[0054] Put 10kg of quartz sand into the muffle furnace, roast at 300°C for 10min, then transfer the roasted quartz sand to the sand mixer, and add 0.24 kg of ME-2 water-based epoxy resin, 0.05 kg of carbon black (purchased from Dainichi Seika Chemical Co., Ltd., H190), continue to stir, and when the temperature drops to 130 ° C, add 0.6 kg of hexamethylene tetrachloride to the mixture amine, and stirred for 120s to obtain coated quartz sand, the average particle diameter of which was measured by a digital stereo microscope to be 1 mm.

[0055] (2) Formation of permeable bricks:

[0056] Mix 600g of ceramsite (purchased from Anhui Zijin Ceramsite Factory, with an average particle diameter of 7mm), 12g of cement and 10g of water to obtain a mixture that forms a permeable base; lay the mixture to a si...

Embodiment 3

[0058] This embodiment is used to illustrate the permeable brick provided by the present invention and its preparation.

[0059] (1) Formation of the second aggregate particles:

[0060] Put 10kg of raw sand into the muffle furnace, roast at 300°C for 10 minutes, then transfer the roasted raw sand to the sand mixer, and add 0.12 kg of HD-RHA308 water-based acrylic resin, 0.03 kg of carbon black (purchased from Dainichi Seika Chemical Co., Ltd., H190), and continue to stir for 80 s to obtain the coated raw sand. The average particle diameter measured by a digital stereo microscope is 0.5 mm.

[0061] (2) Formation of permeable bricks:

[0062] 1000g expanded vermiculite (purchased from Yatong Mineral Powder Factory in Lingshou County, with an average particle diameter of 5mm), 60g cement and 60g water are mixed uniformly to obtain a mixture forming a permeable base; the mixture is laid to a size of 30 cm × In a steel permeable brick mold of 60 cm x 10 cm, the laying thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com