Method of producing composite component coated with friction layer

A friction layer and component technology, applied in the corresponding component field, can solve the problems of unusable brake pads and high wear, and achieve the effect of easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

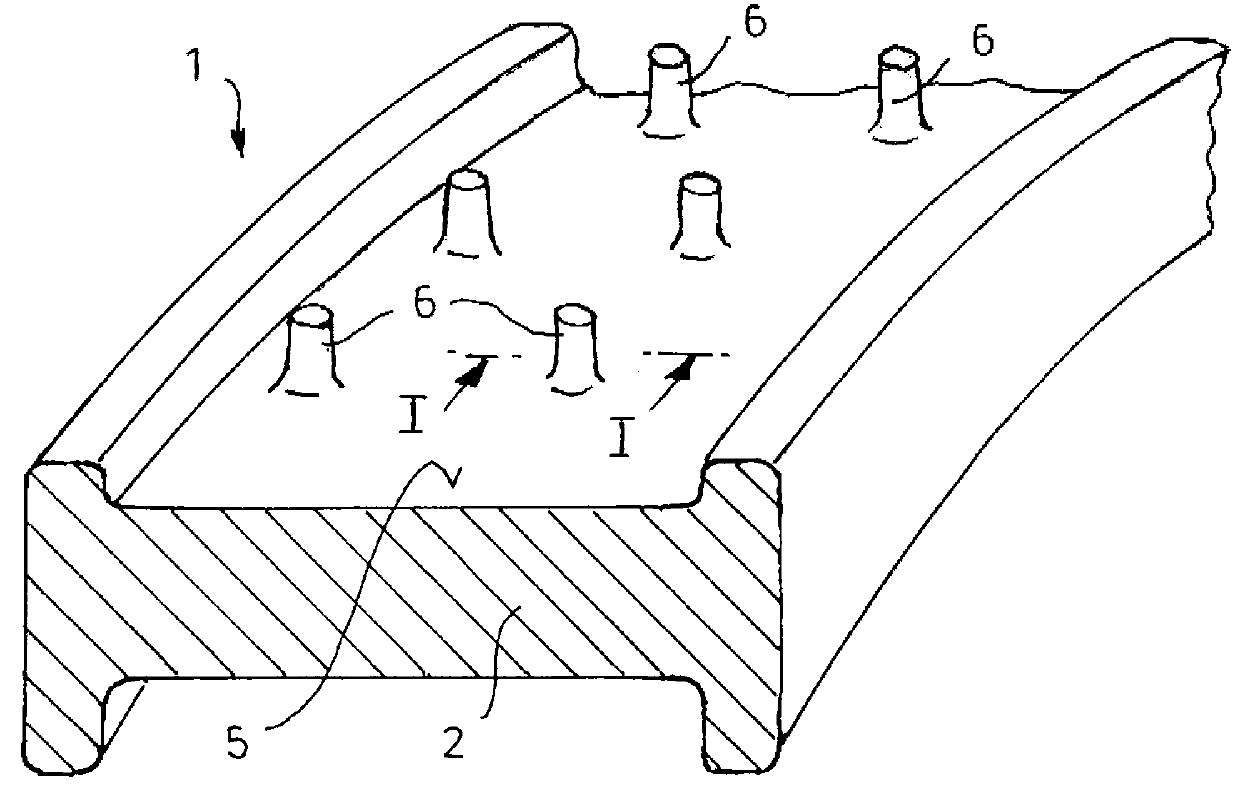

[0041] In all the figures the brake pad assembly is shown with 1 as a whole.

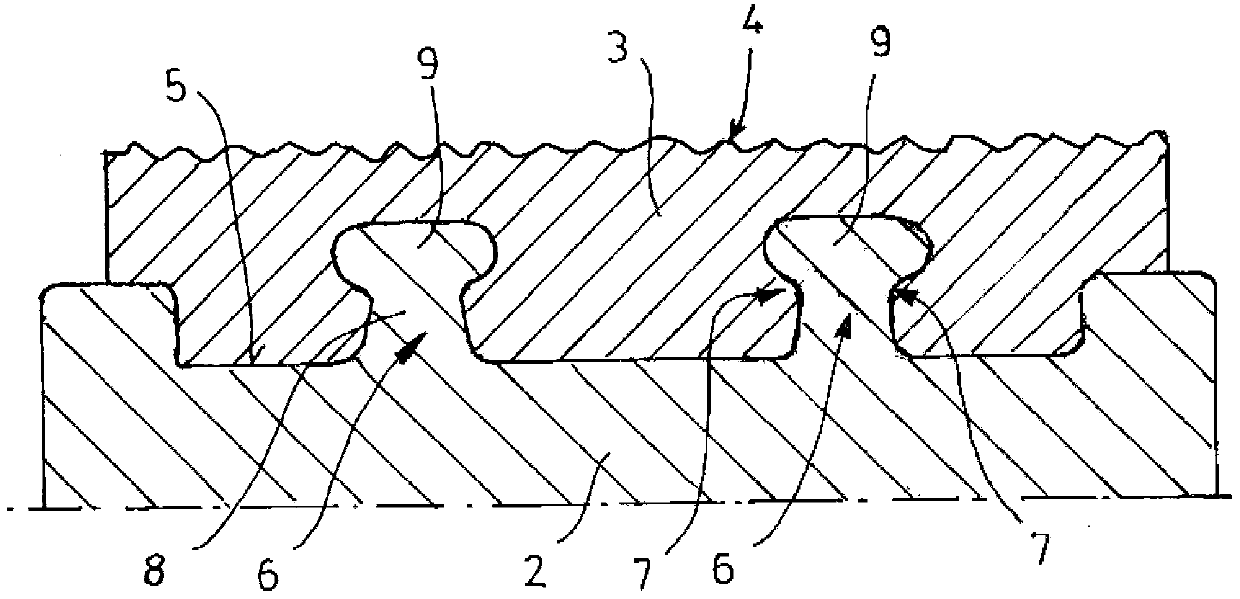

[0042] This consists of an aluminum cast blank 2 on which a friction layer 3 is applied to provide the actual braking surface 4 .

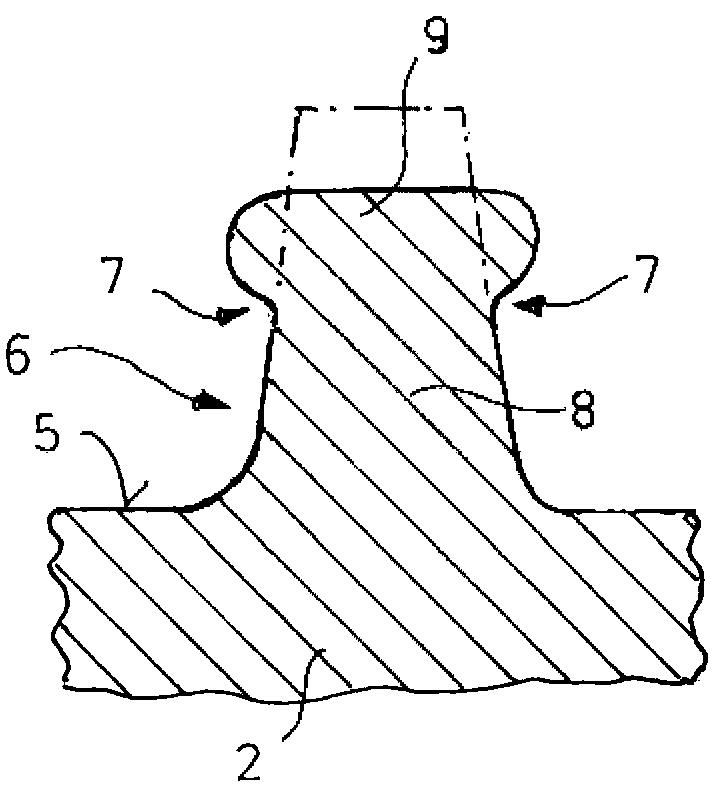

[0043] In order to be able to apply and fix the friction layer by thermal spraying on the light metal surface 5 of the cast blank 2, the surface 5 is equipped with protrusions 6, which are formed during casting and obtain the rear section 7 in a subsequent processing step .

[0044] The protrusions 6 are formed as needle-shaped protrusions and are distributed at regular intervals from one another on the surface 5 to be coated.

[0045] They point upwards or away from the aluminum surface 5 for better release of the blank 2 after casting, and here actually have the shape of a truncated cone or a hyperboloid of revolution with obtuse angles.

[0046]Said rear section 7 is inserted into the protrusion 6 in a step after casting and in a step between thermal spraying. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com