Polypropylene microporous membrane and preparation method thereof

A technology of polypropylene microporous membrane and polypropylene, which is applied in the direction of electrical components, circuits, battery pack parts, etc., can solve the problems of high cost of precision equipment, waste of production capacity, etc., and achieve good size and distribution uniformity, and good microscopic uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

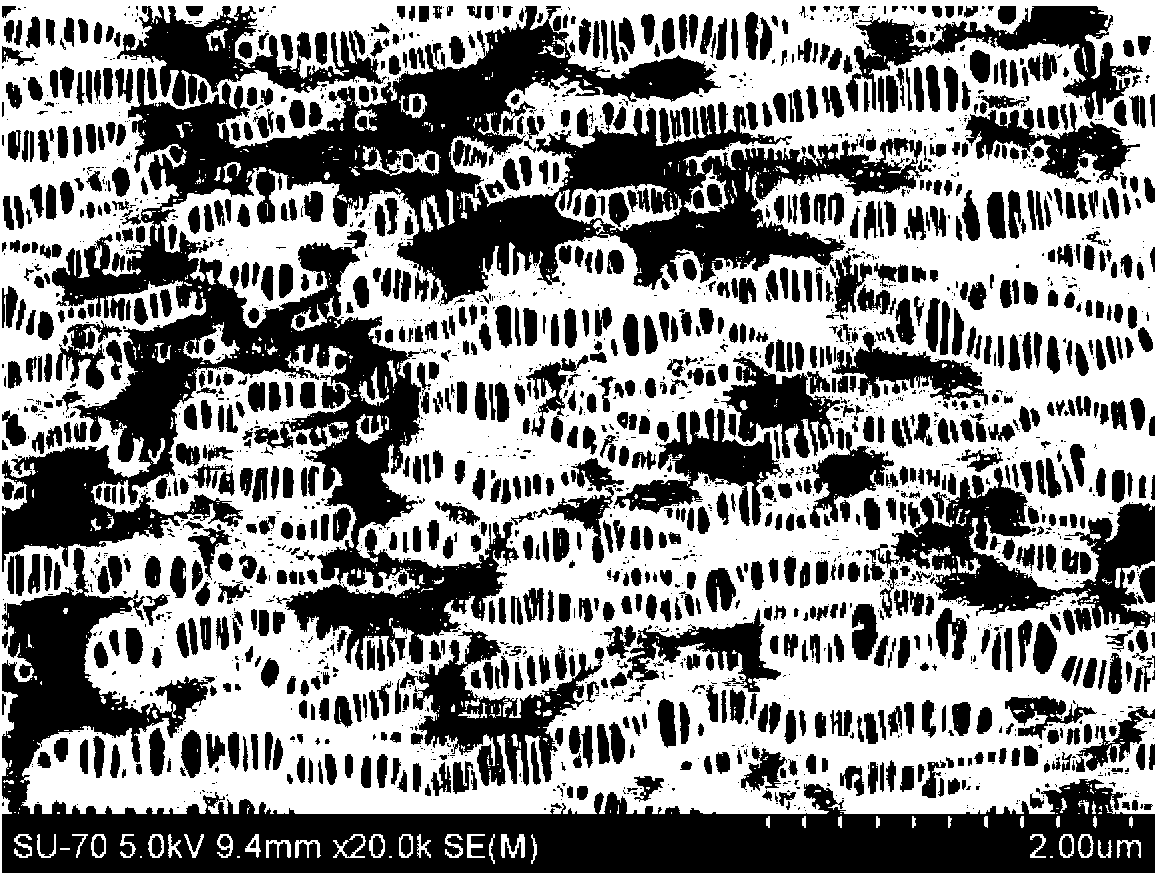

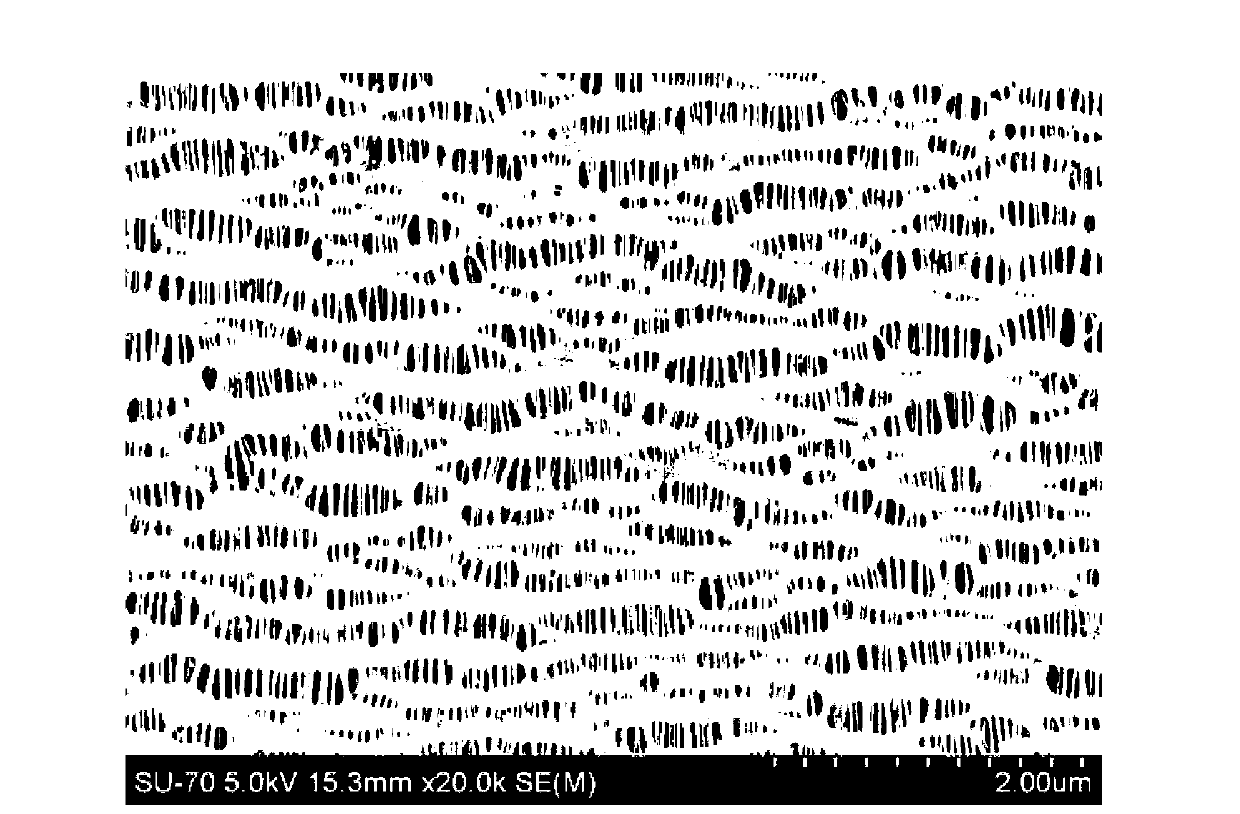

Embodiment 1

[0030] Using a weight average molecular weight of 80% of the total weight fraction is 3.5×10 5 The polypropylene is the first component, and the weight average molecular weight of the total weight fraction of 20% is 5×10 4 The polypropylene is the second component. Wherein, in the first component, the molecular weight of less than 8% by weight of the first component is lower than 1×10 4 The low molecular weight fraction and less than 8% by weight of the first component have a molecular weight greater than 8×10 5 The high molecular weight fraction, the weight average molecular weight of the first component (M W ) and number average molecular weight (M n ) than M W / M n 4, viscosity average molecular weight (M v ) is 852000. In the second component, having less than 5% by weight of the second component, the molecular weight is less than 1×10 4 The low molecular weight fraction and less than 5% by weight of the second component have a molecular weight greater than 1×10 5...

Embodiment 2

[0032] Using a weight average molecular weight of 80% of the total weight fraction is 5×10 5 The polypropylene is the first component, and the weight average molecular weight of the total weight fraction of 20% is 5×10 4 The polypropylene is the second component. Wherein, in the first component, the molecular weight of less than 8% by weight of the first component is lower than 1×10 4 The low molecular weight fraction and less than 8% by weight of the first component have a molecular weight greater than 8×10 5 The high molecular weight fraction, the weight average molecular weight of the first component (M W ) and number average molecular weight (M n ) than M W / M n 6, viscosity average molecular weight (M v ) for 753000. In the second component, having less than 5% by weight of the second component, the molecular weight is less than 1×10 4 The low molecular weight fraction and less than 5% by weight of the second component have a molecular weight greater than 1×10 5 ...

Embodiment 3

[0034] Using a weight average molecular weight of 90% of the total weight fraction is 3.5×10 5 The polypropylene is the first component, and the weight average molecular weight of 10% of the total weight fraction is 5×10 4 The polypropylene is the second component. Wherein, in the first component, the molecular weight of less than 8% by weight of the first component is lower than 1×10 4 The low molecular weight fraction and less than 8% by weight of the first component have a molecular weight greater than 8×10 5 The high molecular weight fraction, the weight average molecular weight of the first component (M W ) and number average molecular weight (M n ) than M W / M n 4, viscosity average molecular weight (M v ) is 852000. In the second component, having less than 5% by weight of the second component, the molecular weight is less than 1×10 4 The low molecular weight fraction and less than 5% by weight of the second component have a molecular weight greater than 1×10 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| draft ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com