Electric locomotive traction system

A technology for traction systems and electric locomotives, applied in the direction of electric locomotives, AC induction motor traction, locomotives, etc., can solve the problems of large structure, complex structure, and large space occupation, so as to improve stability and reliability and reduce control units , The effect of reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

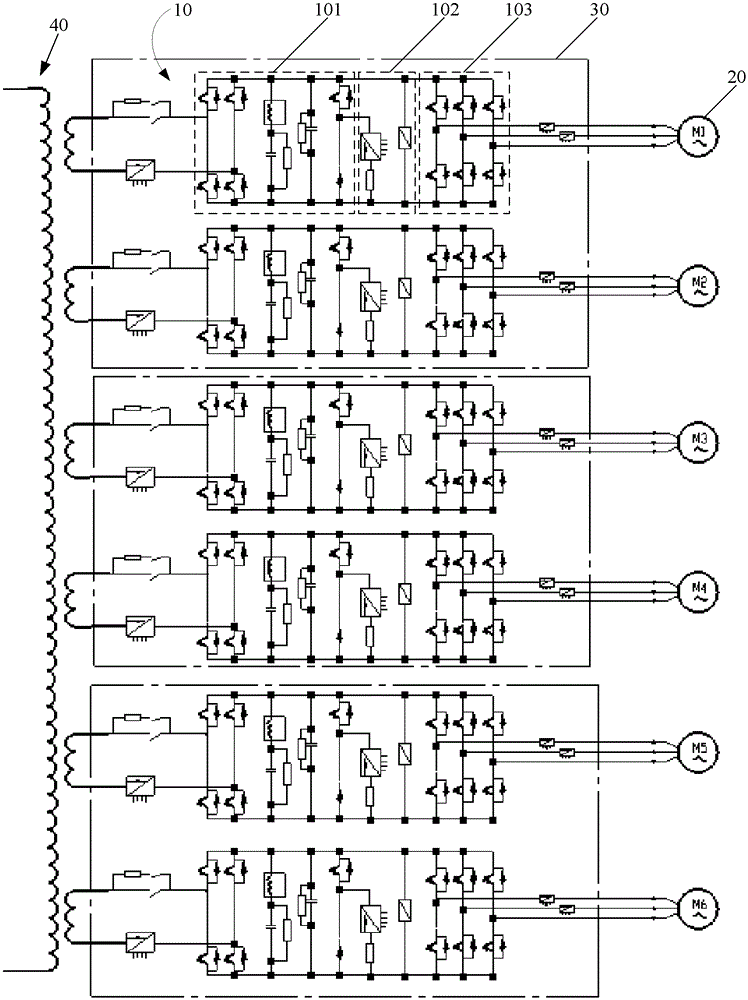

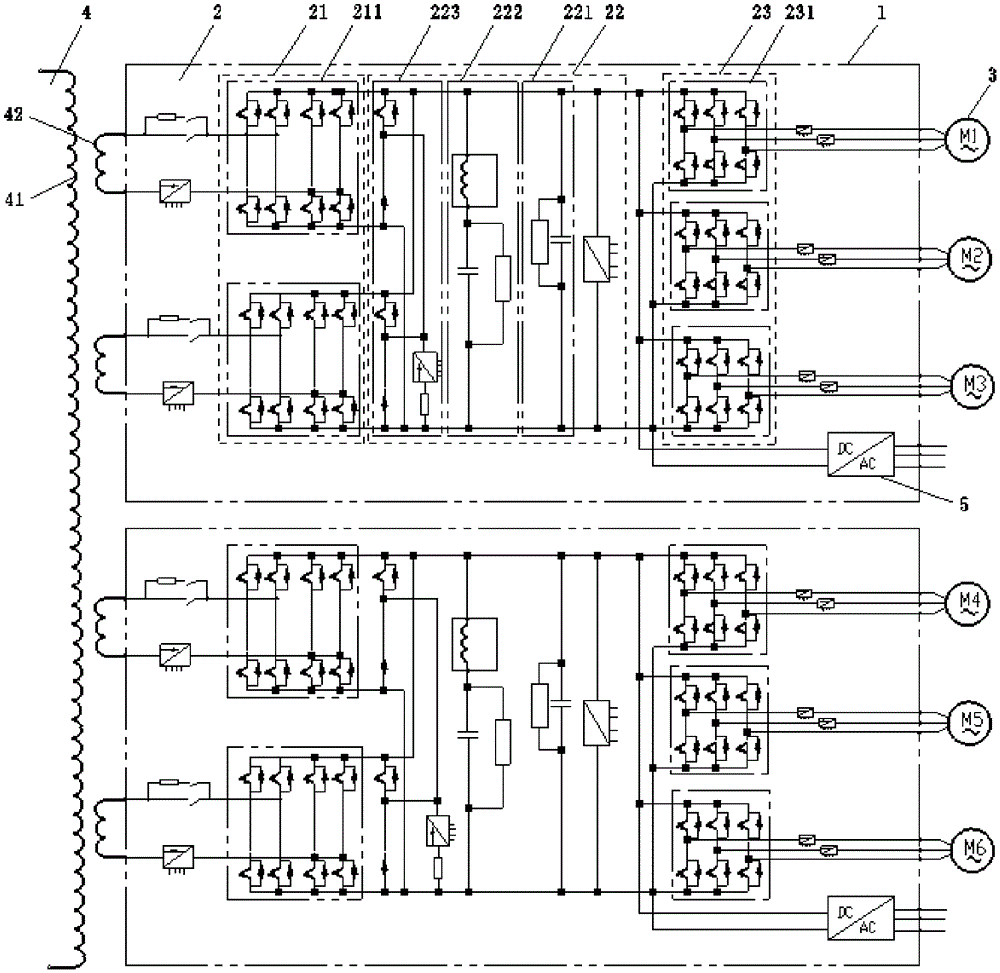

[0017] figure 2 It is a schematic structural diagram of an electric locomotive traction system provided by an embodiment of the present invention. like figure 2 As shown, the electric locomotive traction system of this embodiment includes: two traction converter cabinets 1, each traction converter cabinet 1 is respectively provided with a set of traction converters 2; each traction converter 2 includes sequentially electrically connected A rectifier circuit 21, an intermediate DC transmission circuit 22 and an inverter circuit 23, wherein the rectifier circuit 21 includes two sub-rectifier circuits 211 connected in parallel, and the inverter circuit 23 includes three sub-inverter circuits 231 connected in parallel; The output terminals of the inverter circuit are respectively connected with asynchronous traction motors 3 . The electric locomotive traction system in this embodiment has two traction converter cabinets, and the three sub-inverter circuits in each traction con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com