Novel double-horizontal-shaft concrete mixer

A concrete mixer, twin-shaft technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of difficult to open flocculated material mass, unsatisfactory mixing effect, large mixing shovel area, etc. The effect of labor saving, good mixing quality and short material stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

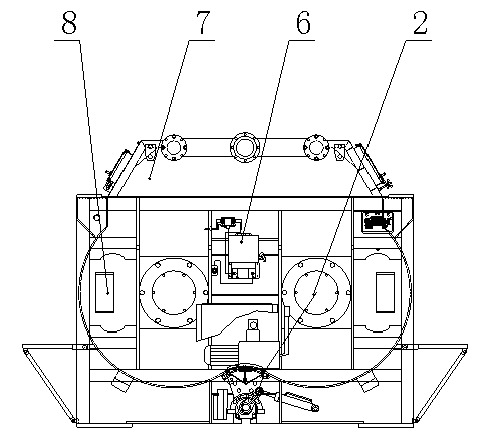

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] 1. Technical requirements:

[0022] 1. The bottom plate of the reducer bracket needs a sealing device for the shaft end of the stirring shaft. After assembly, it is required to be free from warping, parallel, and the bolts are tightened without loosening when rotating.

[0023] 2. The gap between each shovel and the lining plate of the mixing drum is 3-5mm after installation.

[0024] 3. The two ends of the discharge door must be parallel, and the gap between them and the mixing drum should not be greater than 0.5mm.

[0025] 4. The mixer should run smoothly without impact, abnormal vibration and noise.

[0026] 2. Main technical parameters:

[0027] 1. Nominal capacity: 3000L

[0028] 2. Feed capacity: 5000L

[0029] 3. Productivity: 200-240m 3 / H

[0030] 4. Stirring shaft speed: 23.5r / min

[0031] 5. Dimensions: 4000mmx300mmx2000mm

[0032] According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com