Asphalt concrete continuous twin-shaft forced mixer

An asphalt concrete and forced mixer technology, which is applied in clay preparation devices, mixing operation control, cement mixing devices, etc., can solve the problems of reduced equipment productivity, existing material waiting time, inconvenient transportation and installation, etc., and achieves high mixing efficiency and reduced contact. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

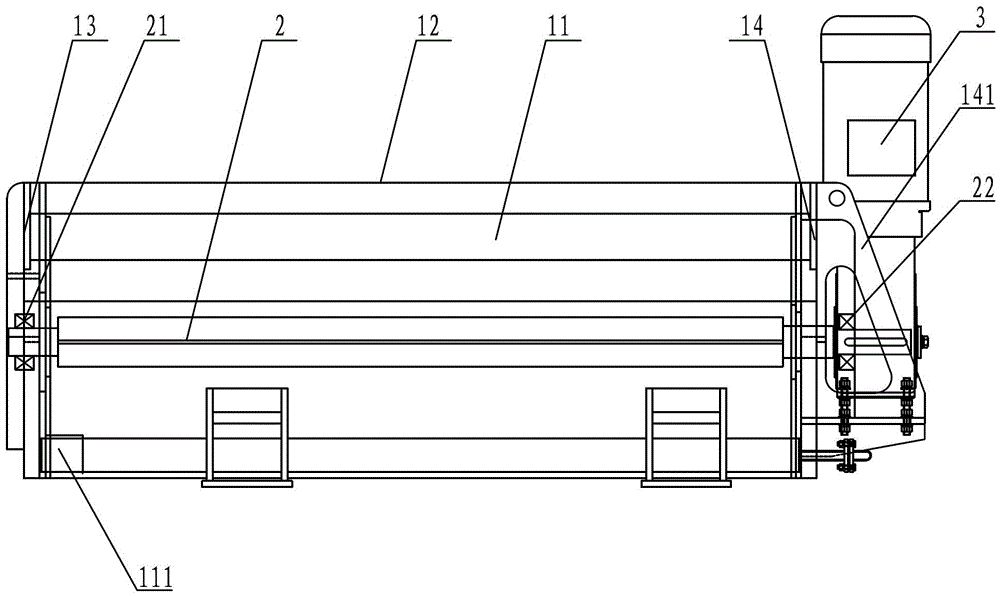

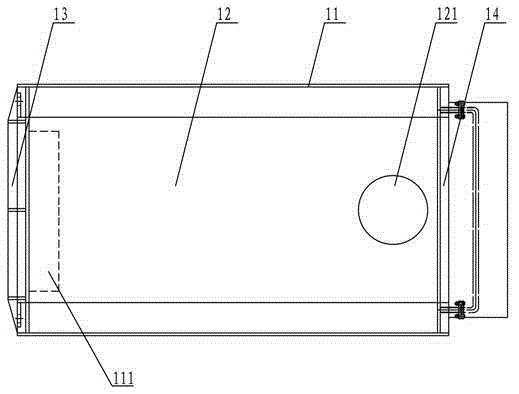

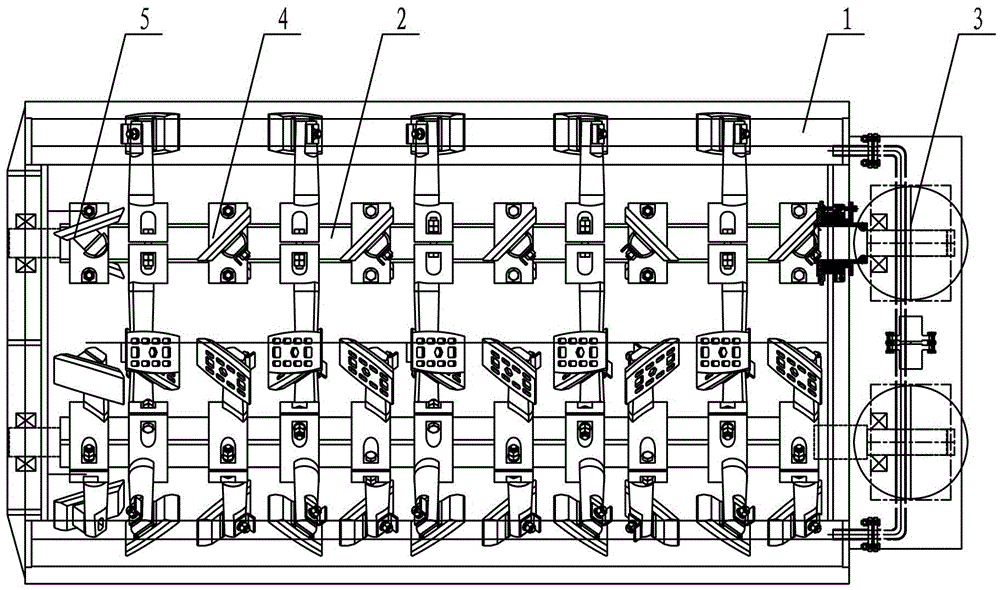

[0032] refer to Figure 1 to Figure 8 As shown, a continuous twin-shaft forced mixer for asphalt concrete includes a mixing tank 1 , a mixing shaft 2 , a driving device 3 , a mixing unit 4 and a scraping unit 5 .

[0033] The mixing cylinder 1 is composed of a mixing cylinder 11, a cylinder upper cover 12, a left side plate 13, and a right side plate 14. The leftmost end of the large arc plate at the bottom of the mixing cylinder 11 has a first discharge port 111, and the cylinder upper cover The right end of 12 has a material inlet 121, the bottom of the left side plate 13 has a second discharge port 131 continuous with the first discharge port 111, and the right side plate 14 is provided with a motor mounting seat 141;

[0034] There are two stirring shafts 2, which are installed in the mixing cylinder 11 in parallel. The left end of the stirring shaft 2 is connected to the shaft end bearing 21 installed on the left side plate 13, and the right end of the stirring shaft 2 is...

specific Embodiment 2

[0038] Specific embodiment two: there are ten stirring groups on each stirring shaft, wherein the ratio of feeding blades and returning blades is adjusted to 8:2, that is, eight groups are equipped with feeding blades, and two groups are equipped with returning blades, and the stirring shaft is fed from From right to left, feed blades, feed blades, feed blades, return blades, feed blades, feed blades, feed blades, feed blades, feed blades, and return blades are installed in turn; two stirring shafts 2 The stirring groups are arranged in a staggered manner to obtain a large shear overlap area. The rest of the components are the same as those in the first embodiment, and will not be repeated here. Compared with the whole mixer, this arrangement of feeding blades and returning blades is suitable for use when the mixing quality of the mixed material is low.

specific Embodiment 3

[0039]Specific embodiment three: ten stirring groups are arranged on each stirring shaft, wherein the ratio of feeding blades and returning blades is adjusted to 6:4. From right to left, feed blades, feed blades, return blades, feed blades, feed blades, return blades, feed blades, return blades, feed blades, and return blades are installed in turn; the stirring on the two stirring shafts 2 The groups are arranged in a staggered manner to obtain a larger clipped overlapping area. The rest of the components are the same as those in Embodiment 1, and will not be repeated here. Compared with the whole mixer, this arrangement is suitable for use when the mixing quality of the mixed material is very high.

[0040] refer to Figure 1 to Figure 8 As shown, the working process of the asphalt concrete continuous twin-shaft forced mixer provided by specific embodiment one, specific embodiment two, and specific embodiment three is as follows:

[0041] The stirring shaft 2 in the mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com