On-line computation method of hot continuous rolling rough rolling short stroke curve parameters

A technology of curve parameters and calculation methods, which is applied in the direction of tail end control, etc., can solve the problems that the large amount of calculation cannot realize online operation, and the influence of multi-pass back-and-forth rolling is not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

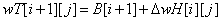

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0050] Taking a slab with a thickness of 234mm, a width of 1550mm, and a steel grade of HQ235B to produce an intermediate slab with a thickness of 55mm and a width of 1510mm as an example, the rough rolling is rolled in 5 passes, and multi-pass reversible rolling is adopted.

[0051] The set thickness and width of the strip at the entrance and exit of each pass of rough rolling are shown in Table 1 (the unit is mm, both are calorific values).

[0052] Table 1 The thickness and width of the strip at the entrance and exit of each pass

[0053]

1st pass

2nd pass

3rd pass

4th pass

5th pass

Inlet thickness H[i] / mm

234.531

186.219

139.141

100.056

72.887

Outlet thickness h[i] / mm

186.219

139.141

100.056

72.887

55.825

Entrance width B[i] / mm

1560.141

1547.002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com