Extraction method based on waterhyacinth surface active agent substance

A surfactant and extraction method technology, applied in chemical instruments and methods, chemical/physical processes, dissolution, etc., can solve the problems of lack of competitiveness in cost and performance, and achieve easy operation, simple and easy method, and remarkable effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The extraction of surface active substances in fresh water hyacinth leaves comprises the following steps:

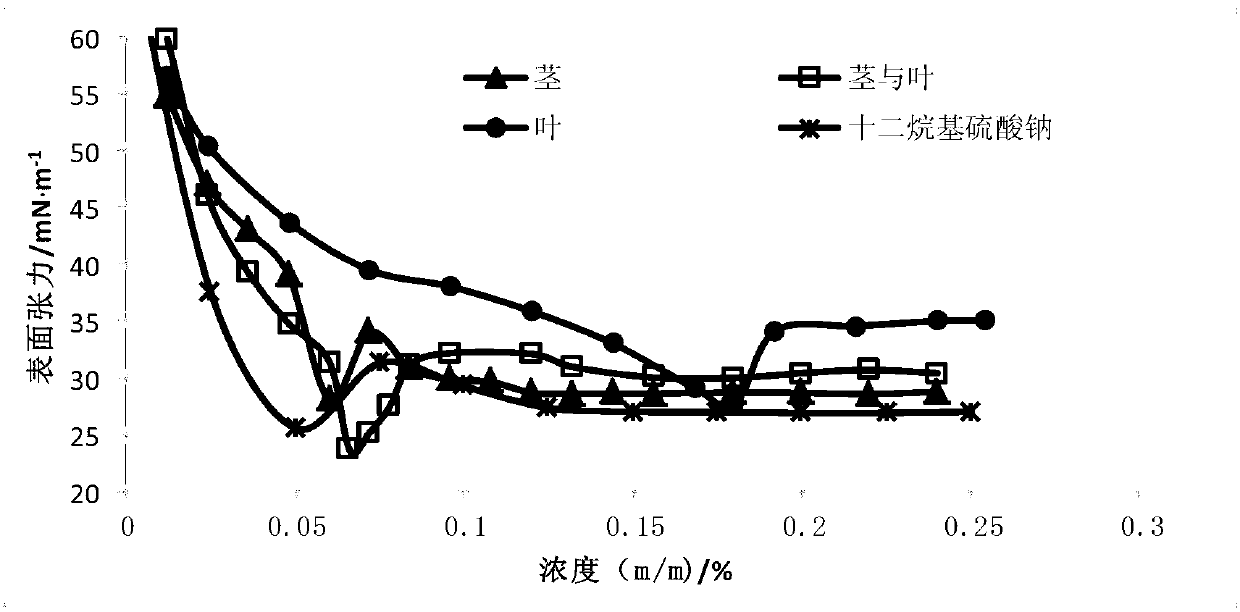

[0032] Fully crush the fresh water hyacinth leaves that have been dried indoors, weigh 100g of water hyacinth leaves in a 600ml beaker, add 500ml of 50% ethanol solution, extract at 40°C for 6 hours and filter to obtain part of the filtrate; Under leaching for 6h, another part of the filtrate was filtered. The two filtrates were combined and concentrated under vacuum rotation at 55°C to obtain 6 g of a solid viscous product.

[0033] The natural surfactant compound application test of water hyacinth comprises the following steps:

[0034] (1) Compounding of fresh water hyacinth leaf surfactant and sodium lauryl sulfate: accurately weigh 0.06g of water hyacinth leaf extract, fully dissolve in distilled water and transfer to a 100ml volumetric flask, accurately weigh 0.05g of twelve Alkyl sodium sulfate was completely dissolved in distilled water, transferred to t...

Embodiment 2

[0039] Extraction of surfactants from fresh water hyacinth stems:

[0040] Fully crush the fresh water hyacinth stems that have been dried indoors, weigh 100g of water hyacinth stems into a 600ml beaker, add 500ml of 50% ethanol solution, extract at 30°C for 8 hours and filter to obtain part of the filtrate; Under leaching for 8h, another part of the filtrate was filtered. The two filtrates were combined and concentrated under vacuum rotation at 55°C to obtain 6 g of a solid viscous product.

[0041] Fresh water hyacinth stem natural surface active substance complex application test, including the following steps:

[0042] (1) Compounding of fresh water hyacinth stem surfactant and sodium lauryl sulfate: accurately weigh 0.07g fresh water hyacinth stem extract, fully dissolve in distilled water and transfer to a 100ml volumetric flask, accurately weigh 0.05g ten Sodium dialkyl sulfate was completely dissolved in distilled water, transferred to the aforementioned 100ml volume...

Embodiment 3

[0047] Extraction of surfactants from fresh water hyacinth stems and leaves:

[0048] Fully crush the fresh water hyacinth stems and leaves that have been dried indoors, weigh 100g of water hyacinth stems and leaves in a 600ml beaker, add 500ml of 50% ethanol solution, extract at 50°C for 4h and filter to obtain part of the filtrate; Extracted under the same conditions for 4h, filtered to obtain another part of the filtrate. The two filtrates were combined and concentrated under vacuum rotation at 55°C to obtain 5 g of a solid viscous product.

[0049] Fresh water hyacinth stem and leaf natural surface active substance complex application test, including the following steps:

[0050] (1) Compounding of surfactants from fresh water hyacinth stems and leaves and sodium lauryl sulfate: accurately weigh 0.17g of fresh water hyacinth stem extract, fully dissolve in distilled water and transfer to a 100ml volumetric flask, and accurately weigh 0.05g Sodium lauryl sulfate was compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com