Scroll refrigerating compressor

A refrigerating compressor and scroll-type technology, which is applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of poor sealing effect, low precision, and difficulty in ensuring the positional relationship between the two sealing surfaces, etc. Effect of sealing and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the compressor of the present invention will be described below with reference to the drawings and examples, and the present invention can be better understood through these descriptions.

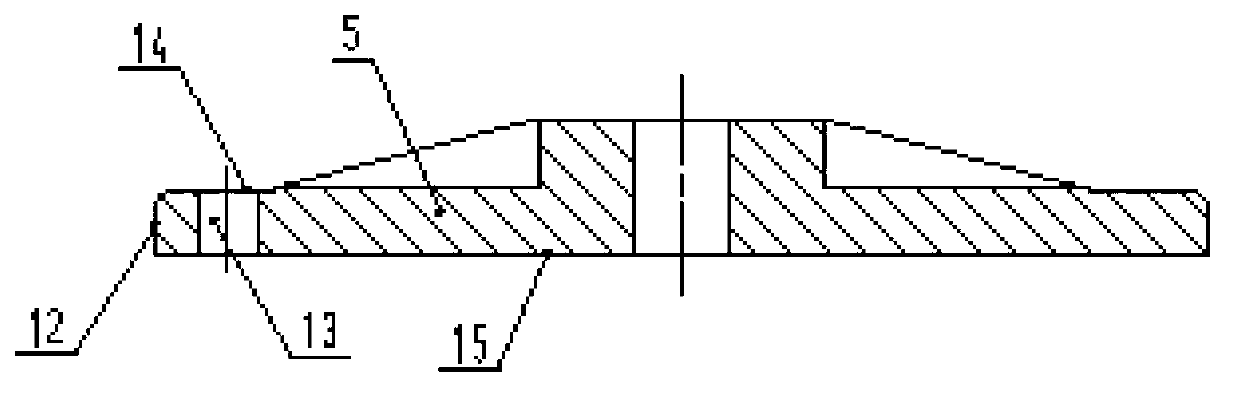

[0022] The scroll refrigeration compressor includes: shell 1, upper cover 3, high and low pressure partition 5, fixed scroll 7, movable scroll 10, Oldham ring, upper support 2, crankshaft, motor rotor, motor stator and more than three Backing ring 4, the backing ring 4 is a cylindrical backing ring with a backing ring through hole 27 in the center, the backing ring 4 is fixedly installed on the upper end surface 25 of the upper support, the difference in the circumferential distance of the backing rings 4 does not exceed 30mm, and the upper end surface of the upper support 25 The position where the backing ring 4 is installed is provided with an upper support bolt hole 24, the high and low pressure partition 5 is placed on the upper end surface of the backing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com