Automatic adjustment brake drum

An automatic adjustment, brake drum technology, applied in slack adjusters, brake types, drum brakes, etc., can solve the problems of constant brake arm travel, large braking sliding distance, and reduced braking effect, and achieves the best performance. Uniform force, avoid dislocation, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

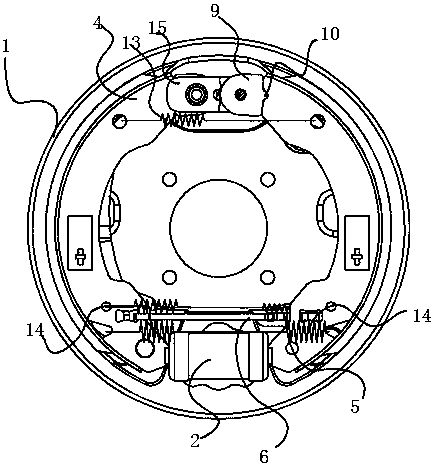

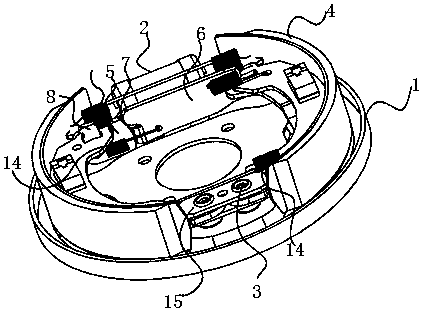

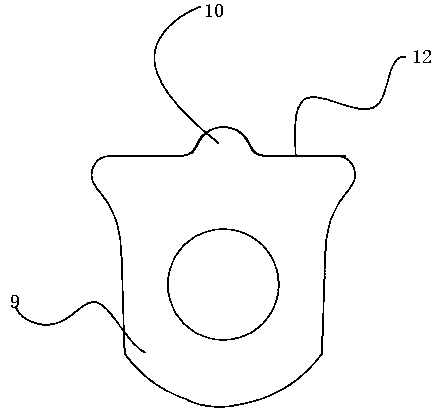

[0025] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

[0026] Such as Figure 1-7 As shown, an automatic adjustable brake drum brake includes a casing 1, and the inner side of the casing 1 is provided with a power transmission device 2, a centering shaft 3, a shoe block 4, an adjustment gear 5 and a hand brake support plate 6; the shoe block 4 is symmetrically arranged On both sides of the power transmission device 2 and the centering shaft 3, one end of the hand brake support plate 6 is fixed on the shoe 4, and the other end has a waist-shaped hole and a limit adjustment tooth 7, and the pin 16 is connected with the adjustment tooth at the waist-shaped hole. The gear 5 is movably connected; one end of the adjustment gear 5 is inserted into the shoe 4 on the other side, and the hand brake support plate 6 and the adjustment gear 5 are set through the meshing of the limit adjustment tooth 7. 1 opens outwards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com