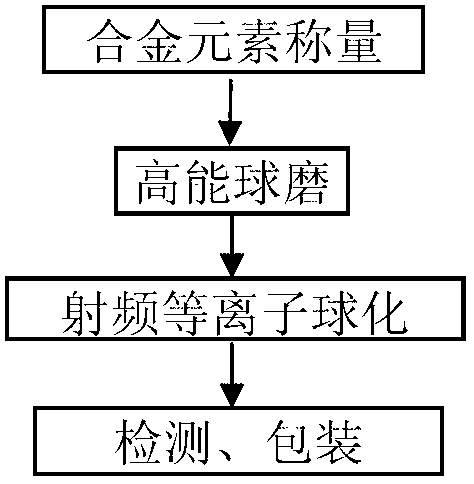

Method for preparing micro spherical niobium (Nb)-wolfram (W)-molybdenum (Mo)-zirconium (Zr) alloy powder

A technology of nb-w-mo-zr, alloy powder, applied in the field of preparing fine spherical Nb-W-Mo-Zr alloy powder, can solve the problems of non-spherical shape and poor fluidity, and achieve high sphericity and good fluidity , fine powder effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: adopt the present invention to prepare fine spherical Nb-5wt%W-2wt%Mo-1wt%Zr alloy powder

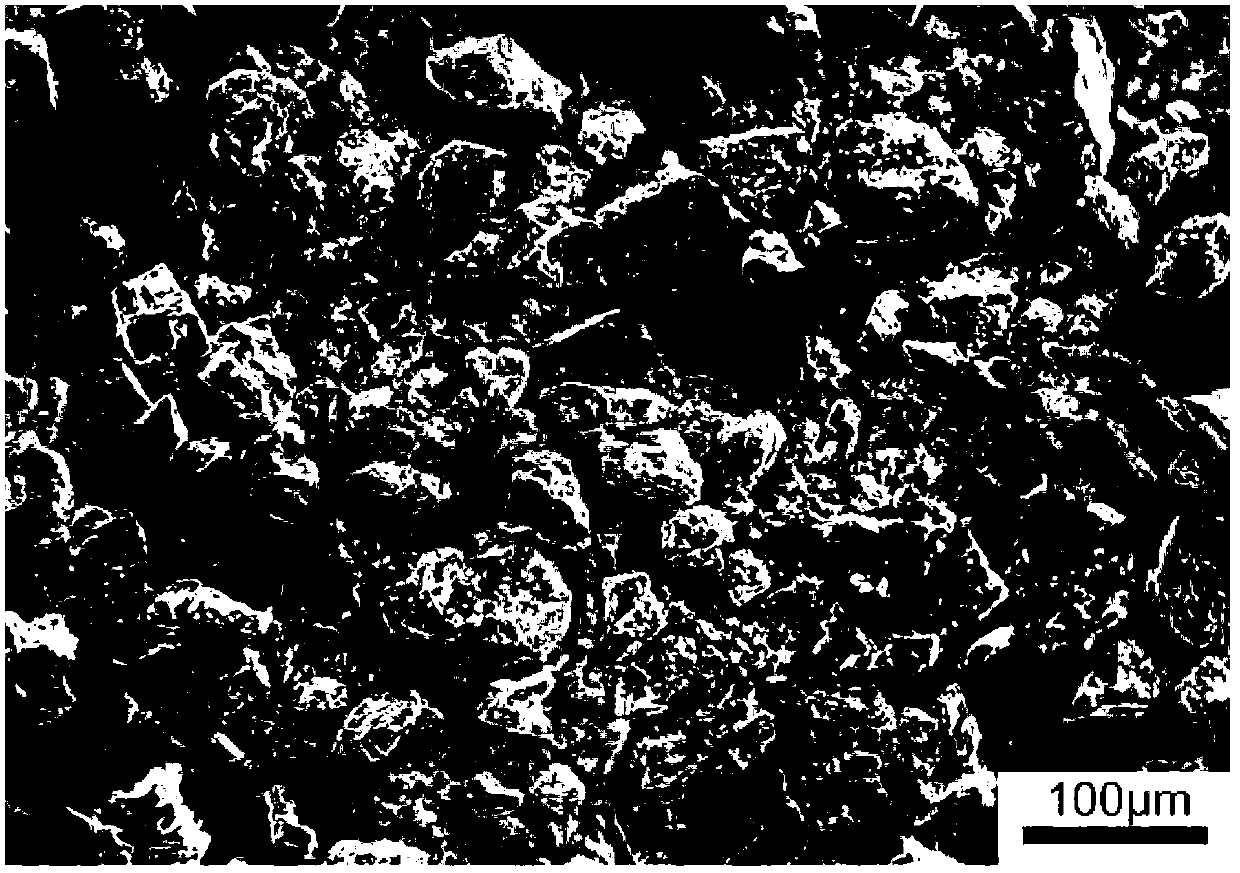

[0027] Nb powder with a purity of >99.8% and a particle size of -325 mesh; W powder with a purity of >99.9% and a particle size of 3-5 μm; Mo powder with a purity of >99.9% and a particle size of 1-2 μm; purity >99.5% with a particle size of 4-8μm Zr powder as raw material;

[0028] According to the alloy composition is Nb-5wt%W-2wt%Mo-1wt%Zr to weigh and mix powder;

[0029] The prepared powder is mechanically alloyed on a planetary ball mill, the ball milling speed is 400r / min, and the ball milling time is 50h;

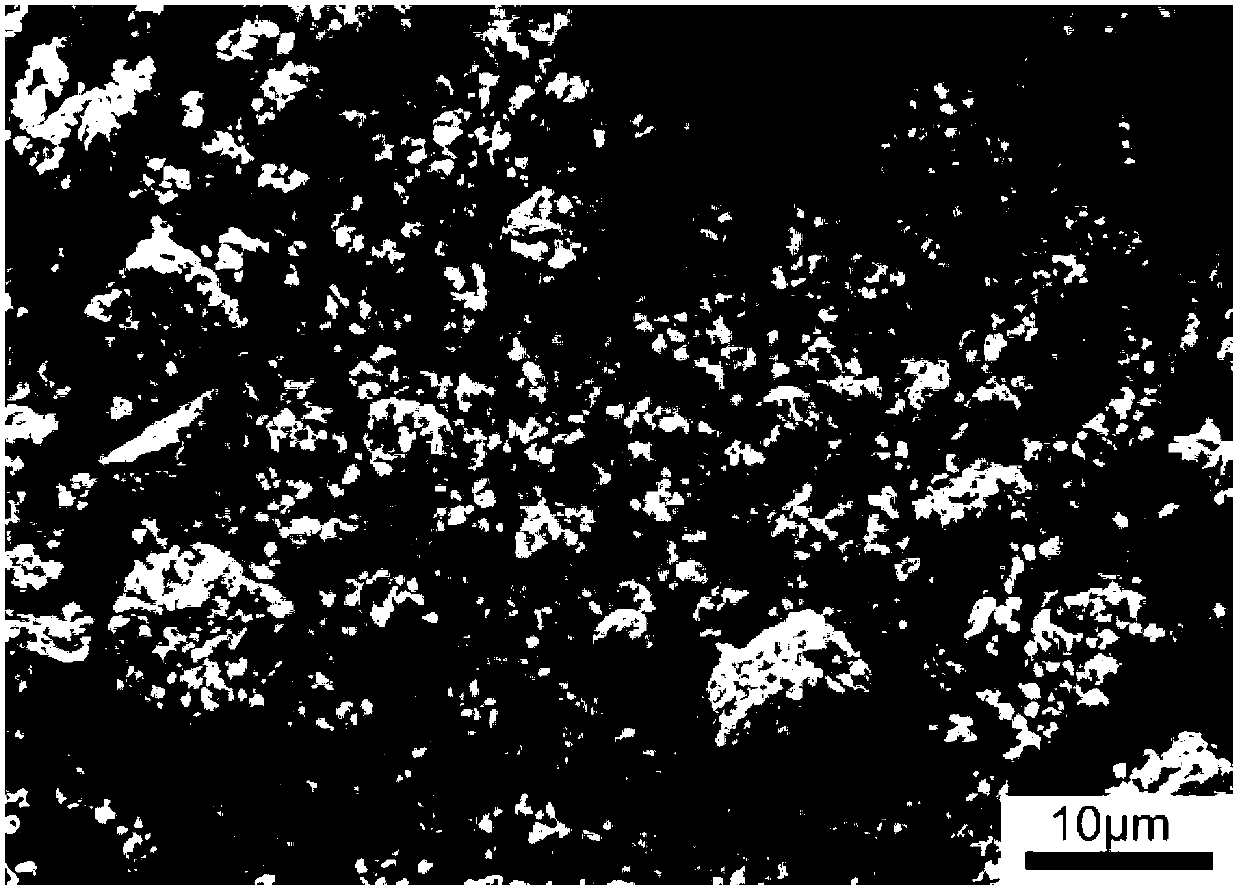

[0030] The powder after mechanical alloying was subjected to radio frequency plasma spheroidization treatment, the equipment power was 70 KW, the feeding rate was 6 g / min, the system pressure was 99 KPa, the flow rates of carrier gas, center gas and edge gas were 2 L / min, 2.5 L / min and 90 L / min;

[0031] The powder after plasma spheroidization is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com