Elastic leather clothing

An elastic material and leather technology, applied in the field of leather clothing, can solve the problems of high tear resistance, sweating, airtightness, etc., and achieve the effect of uniform force distribution and durable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

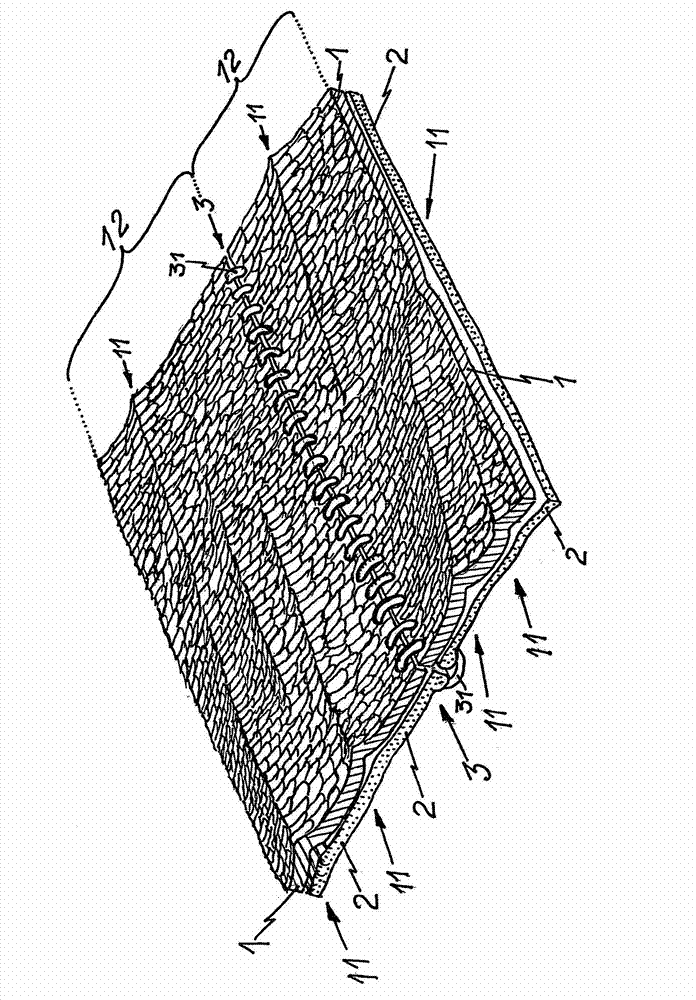

[0034] exist figure 1 , a section is cut out from the seam area of the leather material for illustration purposes and is specifically enlarged. The figure shows a perspective view. At the cutting edge, the outer layer of leather (1) can be considered as the upper layer. In the surface and at the cutting edge, folds ( 11 ) can be clearly discerned. These creases (11) curve upwards, resembling the gable roof of a house, forming upwardly directed pointed edges. It can be seen that this edge is a well-illustrated through-line in the network of the leather (1), which in this example resembles a grain-packed network. It can be deduced from the size of the seam ( 3 ) in the center of the picture that these creases have only a low height relative to the general surface of the leather ( 1 ). In the enlarged portion shown here, it can be seen that the suture (31) is a series of highly curved, ring-like elements, and the suture (31) forms the seam (3), wherein the suture (3) The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com