An Automatic Range Measuring Method for Measuring Digital Storage Oscilloscope

A technology of automatic range and measurement method, which is applied in the direction of digital variable display, range change circuit, etc., can solve problems affecting production efficiency, achieve fast automatic measurement, save time, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

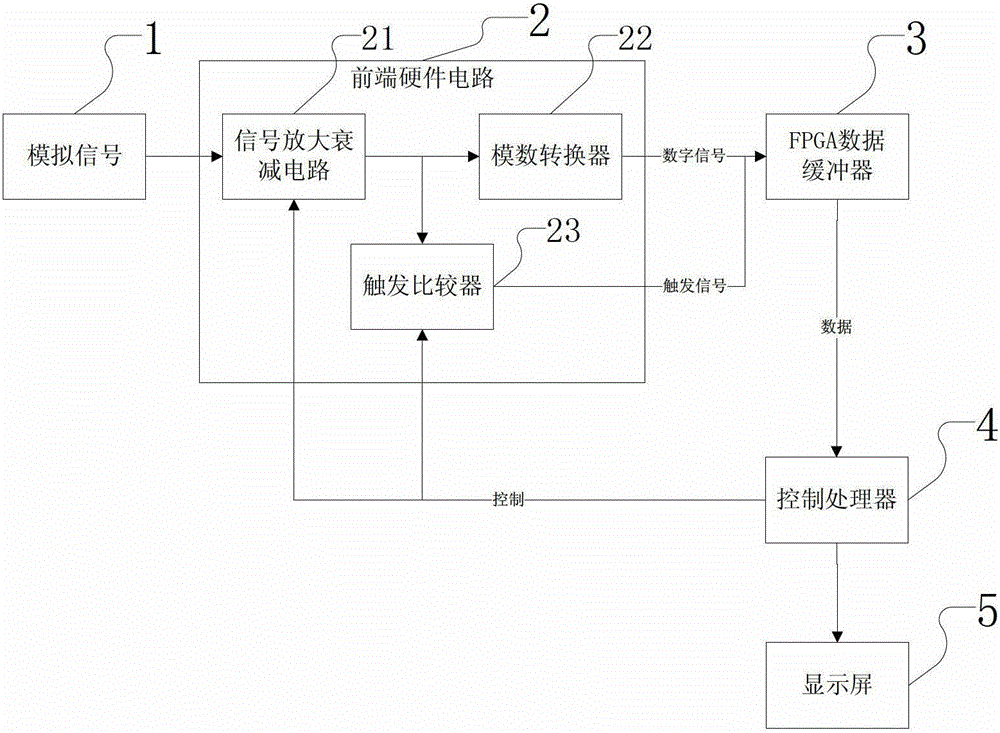

[0048] see figure 1 As shown, an automatic range system for measuring digital storage oscilloscopes includes: FPGA data buffer 3, control processor 4, display 5, and also includes front-end hardware circuit 2, wherein,

[0049] The output end of the front-end hardware circuit 2 is electrically connected to the input end of the FPGA data buffer 3, and the control processor 4 is respectively input to the FPGA data buffer 3, the display 5 and the front-end hardware circuit 2. terminal electrical connection;

[0050] Described front-end hardware circuit 2 further comprises:

[0051] Signal amplification and attenuation circuit 21, used to amplify or attenuate the adopted analog signal;

[0052] Trigger comparator 23, compare according to the signal of described signal amplification attenuation circuit 21 input and the signal that control processor 4 feeds back, generate trigger signal and send to FPGA data buffer 3;

[0053]The analog-to-digital converter 22 is used to convert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com