A large-scale initiation method of digital electronic detonator for engineering blasting

A technology of digital electronic detonator and detonation method, which is applied in blasting and other directions to achieve the effects of reducing environmental pollution, improving detonation safety factor, good network controllability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

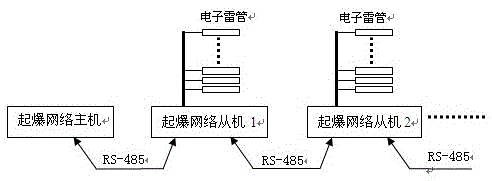

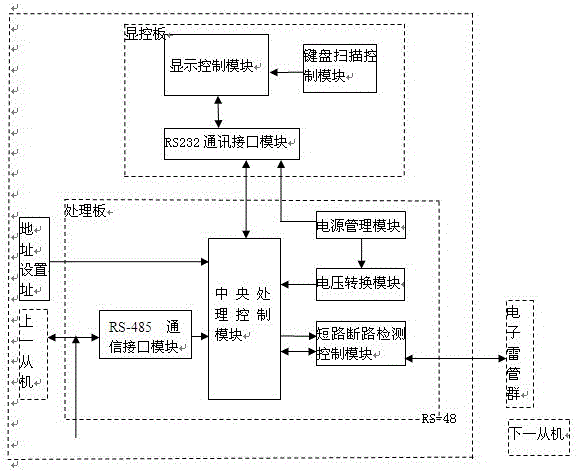

[0039] Such as figure 1 , 2 , shown in 3, 4, a kind of digital electronic detonator large-scale detonation system that is used for engineering blasting comprises: detonation network host computer, detonation network slave machine and electronic detonator controller, described detonation network host computer communicates with RS-485 serial communication cable The first detonation network slave is connected, and the first detonation network slave is respectively connected in series with the n+1 detonation network slave, the n+2 detonation network slave... in sequence through the RS-485 serial communication cable; wherein, Each network detonating slave machine is connected with a group of digital electronic detonators.

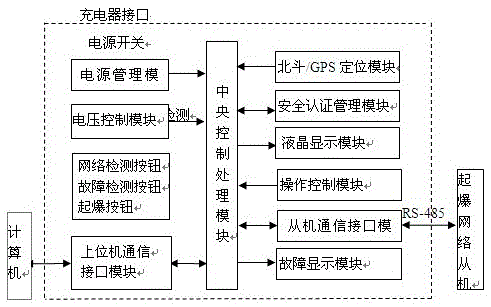

[0040] The detonation network host includes: a central control processing module, an input device, an output device, and a bus communication control module, the input port of the central control processing module is connected with the Beidou / GPS dual-mode posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com