Rock core sealing device and sealing method thereof

A sealing device and core technology, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of core sealing failure, easy plastic deformation of sealing gasket, scrapping of colloidal sealing cylinder, etc., and achieve anti-corrosion ability Strong, good core sealing, and the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

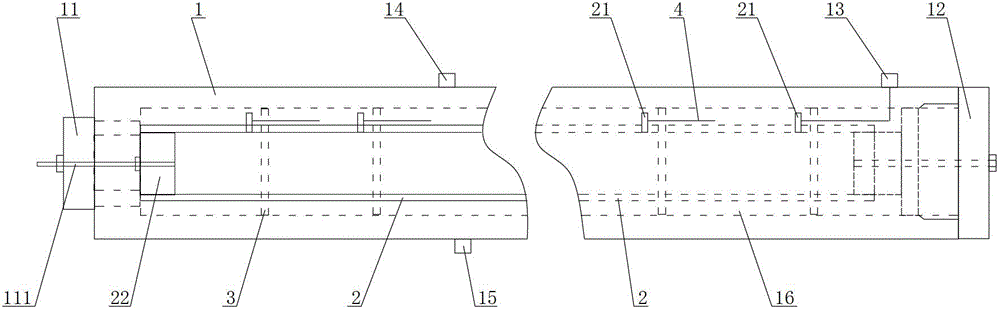

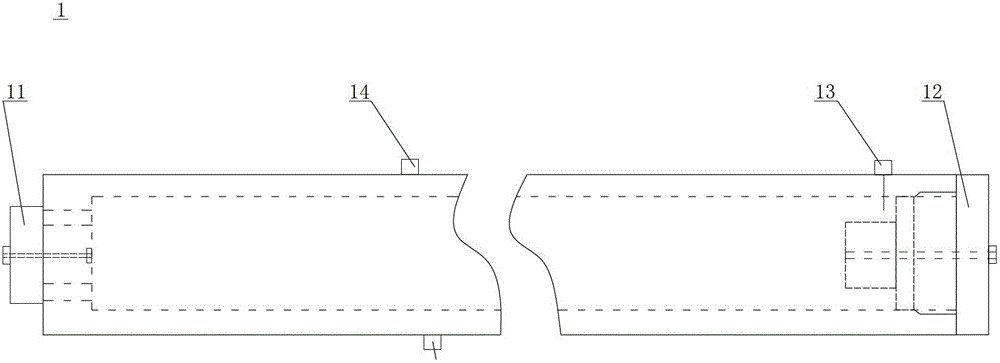

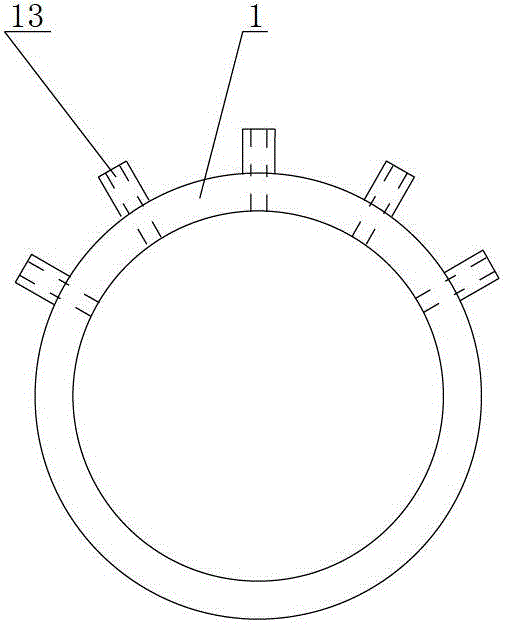

[0050] Such as figure 1 As shown, the present invention provides a core sealing device, which includes an outer cylinder 1, a lead inner cylinder 2 and a plurality of lead inner cylinder supports 3, wherein: one end of the outer cylinder 1 is sealed with a fixed end cover 11, and the other One end is sealed with a floating end cover 12, and a plurality of pressure measuring holes 13 are opened on the wall of the outer cylinder 1 close to the floating end cover 12 along the circumferential direction, and the upper end of the outer cylinder 1 is provided with row The air hole 14 has a confining pressure hole 15 at its lower end; the lead inner cylinder 2 is pierced in the outer cylinder 1, and a plurality of pressure measurement sealing holes 21 are opened on the lead quality inner cylinder 2, and the pressure measurement The sealing hole 21 communicates with the pressure measuring hole 13, one end of the lead inner cylinder 2 is sealed with a sealing block 22, and the other end...

Embodiment approach 2

[0070] see Figure 1-11 As shown, the present invention also provides a core sealing method using the above-mentioned core sealing device to seal the core, and the core sealing method includes the following steps:

[0071] a) providing a core group, the diameter of the core group is 2.5cm;

[0072] b) Assembling the core into the lead inner tube 2 of the core sealing device, setting the lead inner tube support 3 of the core sealing device on the lead inner tube 2, and placing the lead The inner cylinder 2 is inserted into the outer cylinder 1 of the core sealing device;

[0073] c) inject water into the annular space 16 between the outer cylinder 1 and the lead inner cylinder 2 through the confining pressure hole 15 of the core sealing device, and wait for the air in the annular space 16 to flow from the outer cylinder After the exhaust hole 14 of 1 is exhausted, close the exhaust hole 14 and continue to inject water into the annular space 16;

[0074] d) After the water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com