Heat-conducting silica gel sheet and manufacturing method thereof

A technology of heat-conducting silica gel sheet and heat-conducting powder, which is applied in the direction of heat exchange materials, chemical instruments and methods, adhesives, etc., can solve the problems of dead angle, poor product quality, uneven treatment, etc., and achieve easy disassembly and maintenance, and paste Accurate installation position and high maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

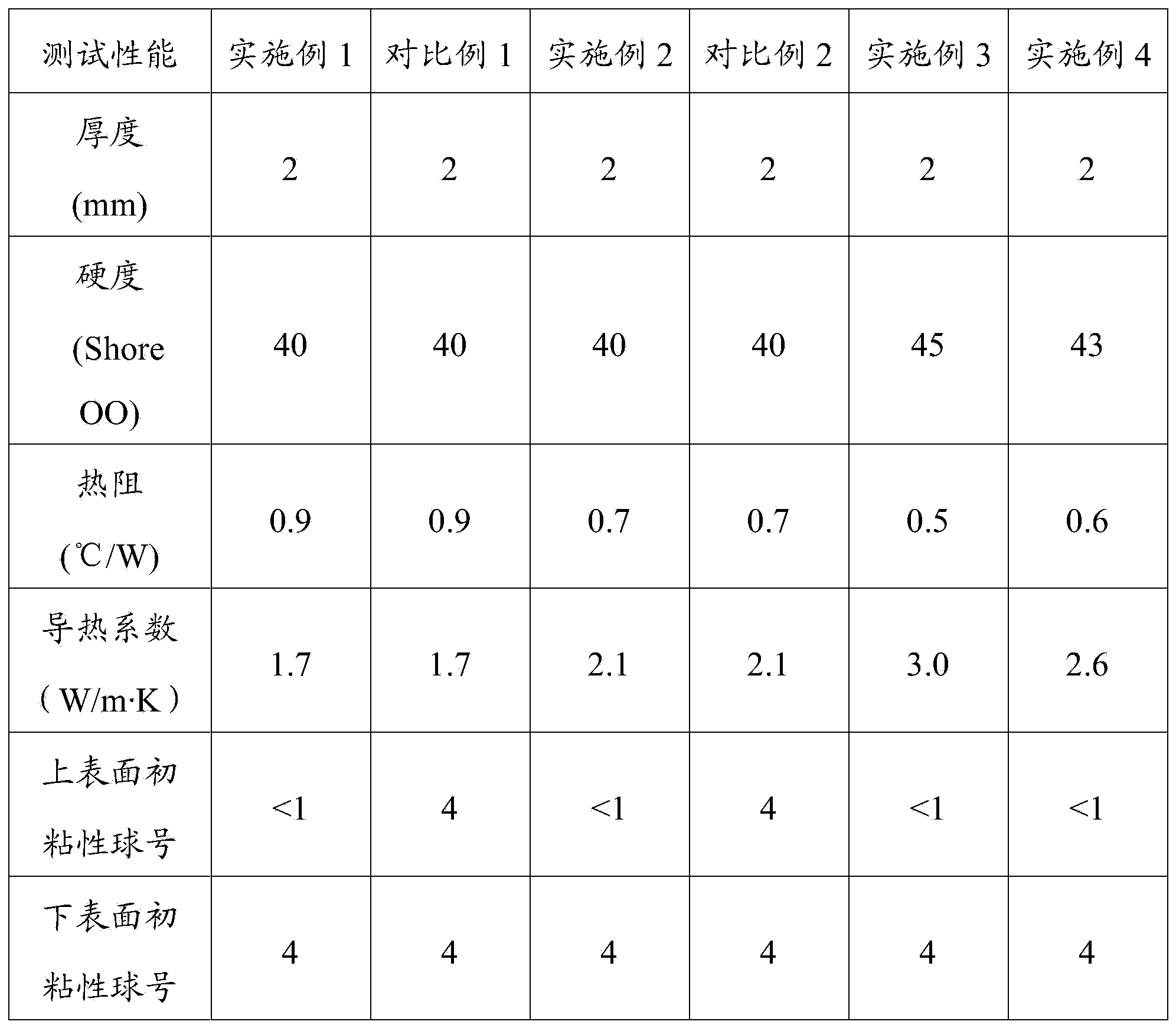

Embodiment 1

[0021] Take 50 parts by weight of 1000mPa·s vinyl-terminated polysiloxane and add it to the reactor, then add 1.2 parts by weight of methyl hydrogen polysiloxane, 3 parts by weight of vinyltrimethoxysilane, and 150 parts by weight The particle diameter of 100 parts is the alumina of 30 microns, the particle diameter of 100 parts by weight is the alumina of 3.5 microns, the platinum catalyst of 0.3 parts by weight, the butynol inhibitor of 0.005 parts by weight, and above-mentioned material is stirred by the vacuum of high-speed power mixer After 30 minutes, a uniformly mixed material was obtained. Fill the mixed material after stirring into a frame-shaped mold with a thickness of 2mm. The frame-shaped mold is an open-top mold, which is convenient for the upper surface of the material to be solidified and formed. After the material loaded into the frame mold is leveled, the excess material is scraped out with a scraper. Put the mold with the mixed material into the oven, and c...

Embodiment 2

[0025] Take 50 parts by weight of 500mPa·s vinyl-terminated polysiloxane into the reaction kettle, then add 2 parts by weight of methyl hydrogen polysiloxane, 3 parts by weight of γ-methacryloxypropane Trimethoxysilane, 120 parts by weight of aluminum powder with a particle size of 15 microns, 80 parts by weight of aluminum powder with a particle size of 4 microns, 0.3 parts by weight of platinum catalyst, 0.005 parts by weight of butynol inhibitor, the above The material was vacuum stirred by a high-speed power mixer for 40 minutes to obtain a uniformly mixed material. Fill the mixed material after stirring and mixing into a frame mold with a thickness of 2mm. After the material loaded into the frame mold is leveled, use a scraper to scrape off the excess material, then put the rubber material and the mold together in the oven, and cure at 120°C for 10 minutes. Silicone sheet.

Embodiment 3

[0029] Take 50 parts by weight of 1000mPa·s vinyl-terminated polysiloxane and add it to the reactor, then add 1.2 parts by weight of methyl hydrogen polysiloxane, 3 parts by weight of vinyltrimethoxysilane, and 300 parts by weight Particle diameter is the alumina powder of 45 microns, and the particle diameter of 200 parts by weight is the alumina of 5 microns, the platinum catalyst of 0.6 parts by weight, the butynol inhibitor of 0.007 parts by weight, and above-mentioned material is vacuumized by high-speed power mixer Stir for 50 minutes to obtain a homogeneous mixture. Fill the mixed material after stirring and mixing into a frame mold with a thickness of 2 mm. After the material loaded into the frame mold is leveled, use a scraper to scrape off the excess material, then put the rubber material and the mold together in the oven, and cure at 150°C for 5 minutes. Silicone sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com