Preparation method of composite material of epoxy resin and closed-cell foamed aluminum

A technology of closed-cell aluminum foam and epoxy resin, which is applied in the field of composite materials, can solve the problems of waste of resources and energy, high production costs, and low yield strength, and achieve reduced environmental pollution, good mechanical properties, and good energy absorption effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step is the pretreatment of the raw material closed-cell aluminum foam block

[0028] The required amount of raw material closed-cell foamed aluminum blocks of random shape and size remaining from processing, wherein each block contains at least one foam body, and the above-mentioned closed-cell foamed aluminum blocks are treated with 0.1mol / L sodium hydroxide lye The body is degreased and decontaminated, and then treated with 0.01mol / L hydrochloric acid until the lye on the closed-cell aluminum foam block is neutralized to enhance its surface activity and optimize its bonding interface with epoxy resin. Put it into a sealed drying box for use;

[0029] The second step, pretreatment of raw epoxy resin

[0030] Preheat the raw material epoxy resin E-44 and curing agent #651 in a 60°C water bath for 1 hour, then weigh the required amount with a balance, and mix the two according to a mass ratio of 1:1. use;

[0031] The third step, preparation of epoxy resin ...

Embodiment 2

[0039] The first step is the pretreatment of the raw material closed-cell aluminum foam block

[0040] The required amount of raw material closed-cell foamed aluminum blocks of random shape and size remaining from processing, wherein each block contains at least one foam body, and the above-mentioned closed-cell foamed aluminum blocks are treated with 0.1mol / L sodium hydroxide lye The body is degreased and decontaminated, and then treated with 0.01mol / L hydrochloric acid until the lye on the closed-cell aluminum foam block is neutralized to enhance its surface activity and optimize its bonding interface with epoxy resin. Put in a sealed dry box for later use

[0041] The second step, pretreatment of raw epoxy resin

[0042] Preheat the raw material epoxy resin E-44 and curing agent #651 in a 60°C water bath for 1 hour, then weigh the required amount with a balance, and mix the two according to a mass ratio of 1:1. use;

[0043] The third step, preparation of epoxy resin and...

Embodiment 3

[0046] The first step is the pretreatment of the raw material closed-cell aluminum foam block

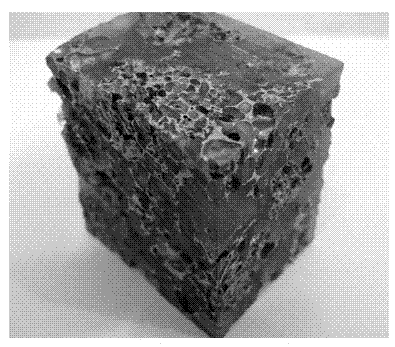

[0047] Cut the required amount of raw closed-cell aluminum foam into a size of 20×20×20mm 3 The block, with 0.1mol / L sodium hydroxide lye, degrease and decontaminate the above-mentioned closed-cell aluminum foam block, and then treat the alkali on the closed-cell aluminum foam block with 0.01mol / L hydrochloric acid The solution is neutralized to enhance its surface activity and optimize its bonding interface with epoxy resin, and then put it into a sealed dry box for use;

[0048] The second step, pretreatment of raw epoxy resin

[0049] Preheat the raw material epoxy resin E-44 and curing agent #651 in a 60°C water bath for 1 hour, then weigh the required amount with a balance, and mix the two according to a mass ratio of 1:1. use;

[0050] The third step, preparation of epoxy resin and closed-cell aluminum foam composite

[0051] Take out the closed-cell foam aluminum block tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com