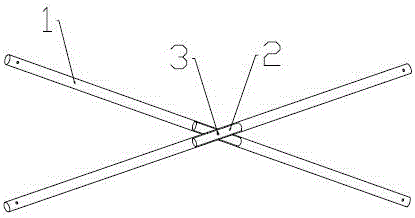

A stent inner plug and stent structure

A technology of bracket structure and plugs, applied in the field of tent brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0016] A bracket inner plug, the cylindrical inner plug is injection molded from glass fiber reinforced polypropylene composite material, the weight percentage of each component in the glass fiber reinforced polypropylene composite material is: polypropylene 60% to 70%, 30% to 40% glass fiber, after the glass fiber reinforced polypropylene composite material is prepared by melting and stirring the mixture of the components, it is injection molded to match the inner wall contour of the bracket to be assembled.

[0017] In an embodiment of the present invention, the weight percentage of each component in the glass fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com