Alcohol-soluble copolyamide and preparation method thereof

A copolyamide, alcohol-soluble technology, applied in the field of polymer material synthesis, can solve problems such as emissions, and achieve the effects of lowering melting point, excellent environmental protection properties, and improving biomass conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

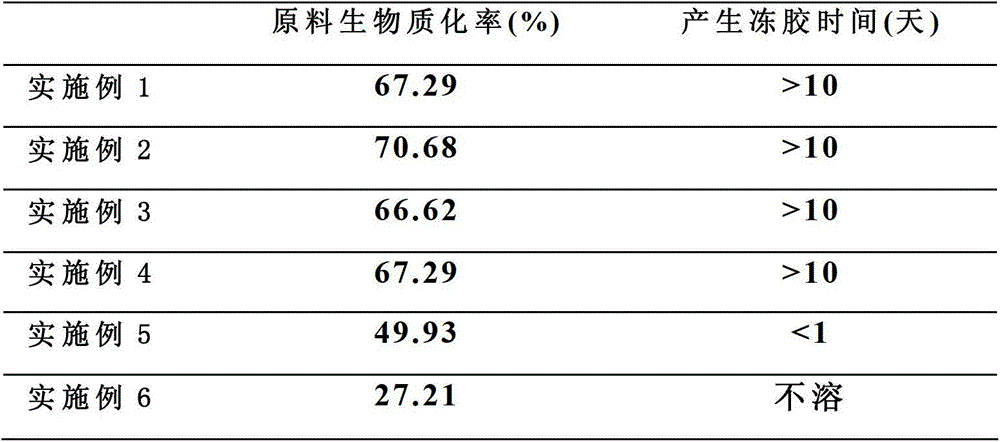

Examples

Embodiment 1

[0023] The preparation of embodiment 1 alcohol-soluble copolyamide

[0024] Prepare as follows:

[0025] The reaction raw materials are fed in the following molar ratio: 20% adipic acid, 10% sebacic acid, 20% furandicarboxylic acid, 20% hexamethylenediamine and 30% decanediamine. Pressure to 1Mpa, heat preservation and pressure for 1 hour, then gradually increase the temperature to 250°C, after 1.5 hours of heat preservation and pressure, start to reduce the pressure and drain water, reduce the pressure to normal pressure within 1 hour, maintain it for 0.5 hours, and then depressurize for 0.5 hours. Then fill in an inert gas to 0.5Mpa, extrude and cool the melt to obtain an alcohol-soluble copolyamide product.

[0026] The product is analyzed by DSC, and the measured melting point (Tm) is 138-146 ° C; at 25 ° C, using sulfuric acid as a solvent, the measured relative viscosity is 1.8;

Embodiment 2

[0027] The preparation of embodiment 2 alcohol-soluble copolyamide

[0028] Prepare as follows:

[0029] The reaction raw materials are fed in the following molar ratio: 10% adipic acid, 15% sebacic acid, 25% furandicarboxylic acid, 25% hexamethylenediamine and 25% decanediamine. Pressure to 1Mpa, heat preservation and pressure for 1 hour, then gradually increase the temperature to 250°C, after 1.5 hours of heat preservation and pressure, start to reduce the pressure and drain water, reduce the pressure to normal pressure within 1 hour, maintain it for 0.5 hours, and then depressurize for 0.5 hours. Then fill in an inert gas to 0.5Mpa, extrude and cool the melt to obtain an alcohol-soluble copolyamide product.

[0030] The product is analyzed by DSC, and the measured melting point (Tm) is 142-147°C; at 25°C, using sulfuric acid as a solvent, the measured relative viscosity is 2.1;

Embodiment 3

[0031] The preparation of embodiment 3 alcohol-soluble copolyamide

[0032] Prepare as follows:

[0033] The reaction raw materials are fed according to the following molar ratio: 10% adipic acid, 10% sebacic acid, 20% furandicarboxylic acid, 20% caprolactam, 10% hexamethylenediamine and 30% decanediamine. Under the nitrogen system, the temperature is raised to 180 ℃, and pressurize to 1Mpa at the same time, after 1.5 hours of heat preservation and pressure, gradually increase the temperature to 250°C, after 1.5 hours of heat preservation and pressure, start to reduce the pressure and drain, reduce the pressure to normal pressure within 1 hour, maintain 0.5 hours and then depressurize 0.5 Hour. Then fill in an inert gas to 0.5Mpa, extrude and cool the melt to obtain an alcohol-soluble copolyamide product.

[0034] The product is analyzed by DSC, and the measured melting point (Tm) is 123-130°C; at 25°C, using sulfuric acid as a solvent, the measured relative viscosity is 2.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com