Preparation method of erythromycin thiocyanate

A technology of erythromycin thiocyanate and erythromycin, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of low yield and high impurity content of erythromycin thiocyanate, etc. Achieve the effects of improving purity, reducing the content of impurities, and reducing the amount of acetone used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

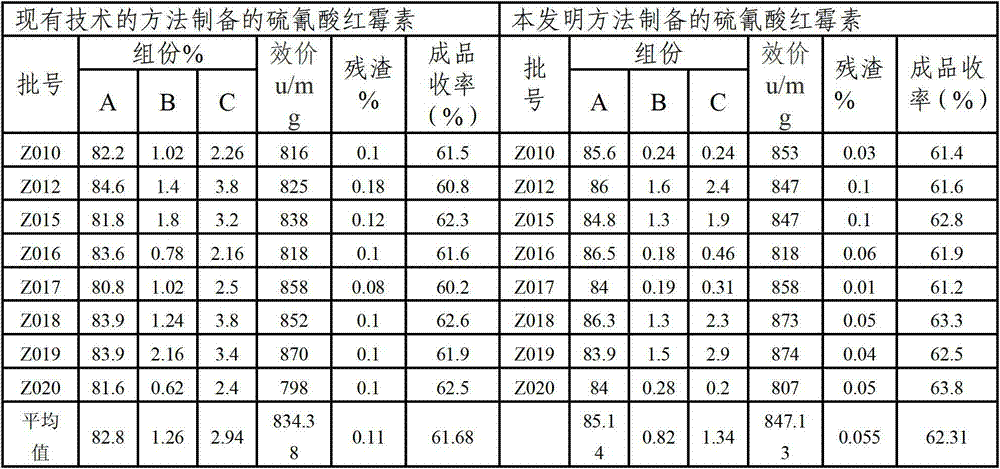

Image

Examples

Embodiment 1

[0023] The preparation method of embodiment 1 erythromycin thiocyanate of the present invention

[0024] Take the crude erythromycin thiocyanate and wash it with purified water at 40°C. The crude erythromycin thiocyanate was dissolved in 1:1 38°C acetone, and the pH value was adjusted to 9.0 with 15% NaOH solution. After the crude erythromycin thiocyanate was completely dissolved, it was washed with saturated sodium chloride solution and separated After the phase, the solution is transferred to the crystallization tank. Add 40% concentration of sodium thiocyanate solution (addition amount: 0.14Kg sodium thiocyanate dry product / billion erythromycin), adjust the pH: 6.0 with 25% acetic acid solution, add according to the volume of the solution at 1:1 Purified water, control the crystallization temperature at 20°C, let it stand for 1 hour, put it into a centrifuge and filter it. The obtained wet product is washed twice with purified water at 50° C., and dried to obtain the fini...

Embodiment 2

[0025] The preparation method of embodiment 2 erythromycin thiocyanate of the present invention

[0026] Take the crude erythromycin thiocyanate and wash it twice with purified water at 60°C. The crude product of erythromycin thiocyanate was dissolved in 1:4 acetone at 48°C, and the pH value was adjusted to 10.5 with 35% NaOH solution. After the crude product of erythromycin thiocyanate was completely dissolved, it was washed with saturated sodium chloride solution. After phase separation, the solution was transferred to a crystallization tank. Add 40% concentration of sodium thiocyanate solution (addition amount: 0.2Kg sodium thiocyanate dry product / billion erythromycin), adjust pH: 7.8 with 50% acetic acid solution, add according to the volume of the solution at 1:2 For purified water, control the crystallization temperature at 30°C, let it stand for 2.5 hours, then put it into a centrifuge and filter it. The obtained wet product is washed twice with 60°C purified water, a...

Embodiment 3

[0027] The preparation method of embodiment 3 erythromycin thiocyanate of the present invention

[0028] A, get erythromycin fermentation liquid 3.5m 3 After adjusting the pH value to 7.2 with 8% lye, use a ceramic membrane with a pore size of 0.1nm to filter, and wash with a certain amount of water to control the titer of the filtrate to 2500u / mI. The filtrate is decolorized by macroporous acrylic acid series strongly basic anion exchange resin. During decolorization, the feed flow rate of the decolorization column is 10BV / h, the pH of the filtrate entering the decolorization column is 6.5, and the pH of the decolorization solution is 6.0. The decolorized filtrate is then concentrated through a nanofiltration membrane. During concentration, the feed pressure is controlled at 0.4 MPa and the concentration temperature is 22°C.

[0029] B. Transfer the concentrated solution into the crude product crystallization tank, add 40% sodium thiocyanate solution (addition amount: 0.18Kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com