Garbage container

A container and garbage technology, applied in garbage collection, trash cans, household appliances, etc., can solve the problems of complex container structure, easy occurrence of garbage scattering and throwing, and poor garbage rebound effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

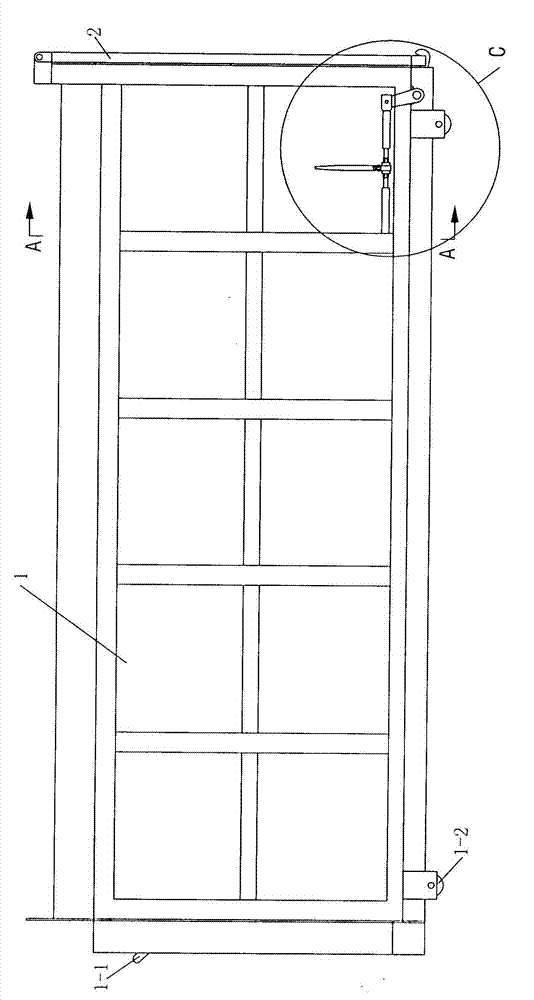

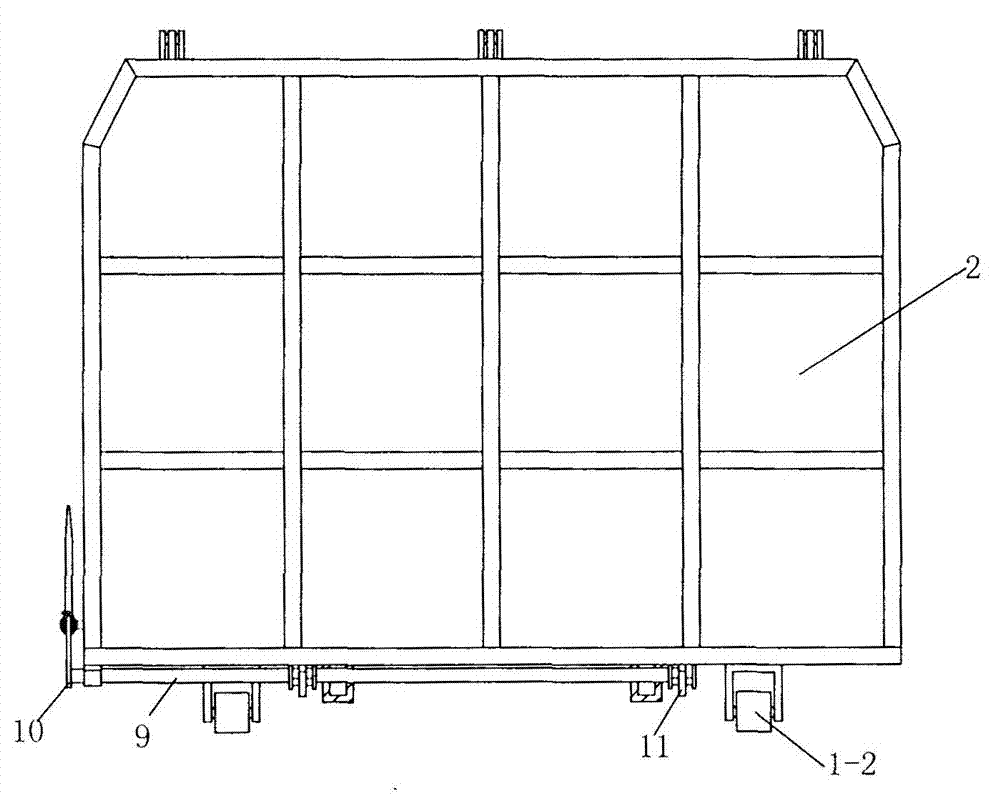

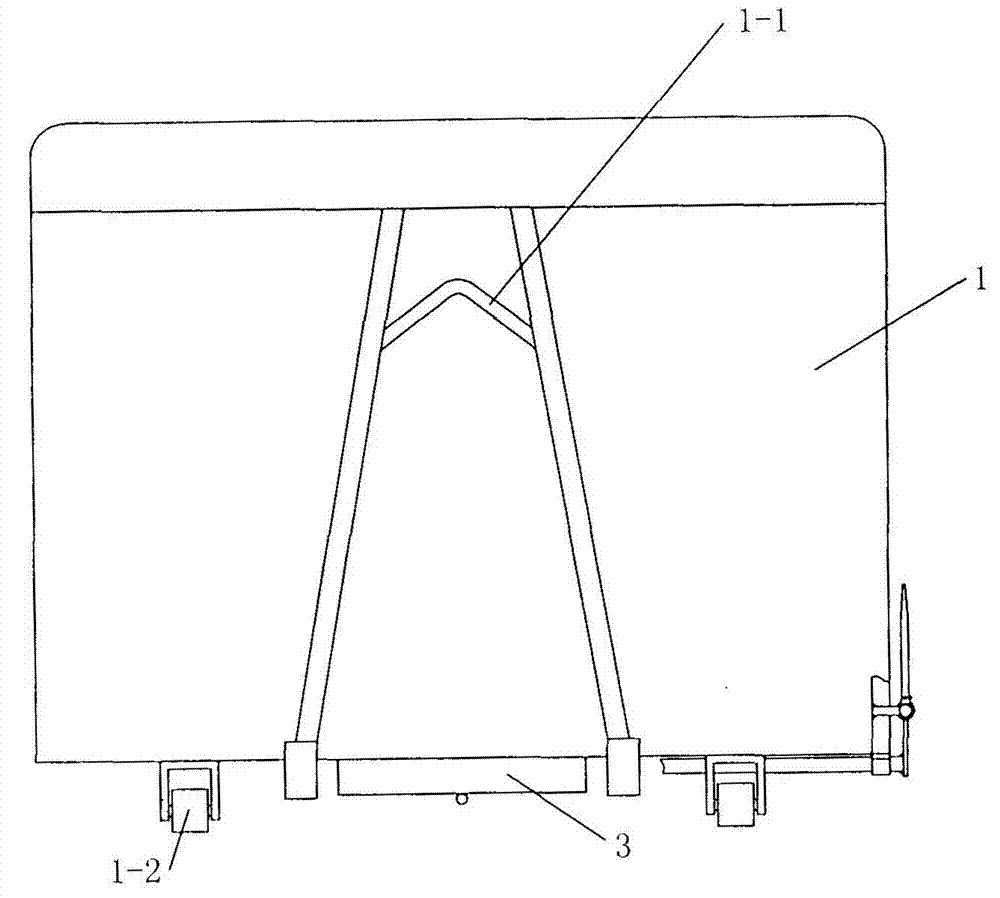

[0032] Such as Figure 1~10 As shown, a garbage container includes a container body 1, a discharge door 2, a top cover door assembly, a discharge door opening mechanism for opening and closing the discharge door 2, and a top cover door assembly door opening mechanism for opening and closing the top cover door assembly The front end of the container body 1 is provided with a lifting hook 1-1, the bottom of the container body 1 is equipped with a pulley block 1-2, the top of the material shortage door 2 is hinged at the rear end of the container body 1, and the opening mechanism of the discharge door is arranged on the discharge door. Between the bottom end of the door 2 and the container body 1, the roof door assembly is installed on the top of the container body 1, and the door opening mechanism of the roof door assembly is arranged between the roof door assembly and the container body 1.

[0033] In order to prevent the leakage of sewage in the garbage, such as Figure 6 , ...

Embodiment 2

[0037] Such as Figure 11~16 As shown, a garbage container includes a container body 1, a discharge door 2, a top cover door assembly, a discharge door opening mechanism for opening and closing the discharge door 2, and a top cover door assembly door opening mechanism for opening and closing the top cover door assembly The front end of the container body 1 is provided with a lifting hook 1-1, the bottom of the container body 1 is equipped with a pulley block 1-2, the top of the material shortage door 2 is hinged at the rear end of the container body 1, and the opening mechanism of the discharge door is arranged on the discharge door. Between the bottom end of the door 2 and the container body 1, the roof door assembly is installed on the top of the container body 1, and the door opening mechanism of the roof door assembly is arranged between the roof door assembly and the container body 1.

[0038] In order to prevent the leakage of sewage in the garbage, such as Figure 6 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com