Device for fixing die and die core

A technology of fixing devices and mold cores, which is applied in the field of processing devices for mold parts, can solve the problems of high mold processing costs, complex mold core shapes, and long processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

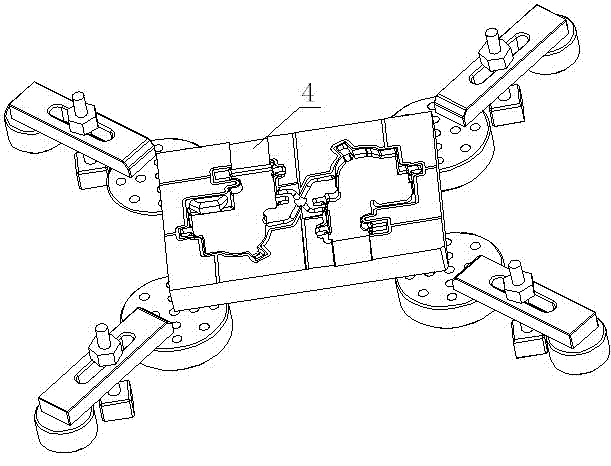

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

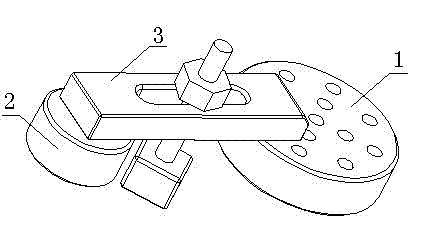

[0012] As shown in the figure, a fixing device for a mold core includes a base 1, a fixing block 2, and a pressing block 3. The upper and lower surfaces of the base 1 are planes, and the parallel base 1 takes the center as the base point and averages along two vertical diameters. Multiple via holes are distributed. The height of the fixed block 2 is the same as that of the base 1. Both the base 1 and the fixed block 2 are processed by a grinder to ensure the level of the machine tool after the mold core is installed. The fixed block 2 and the base 1 are respectively fixed on the pressure block 3 with screws. At both ends, the central position of the pressure block 3 is provided with an oblong via hole.

[0013] Connect the mold core 4 to be processed with the base 1 with screws, then put the mold core 4 and the base 1 together on the workbench of the CNC machine tool, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com