Processing method of round elastic body for sensor

The technology of a circular elastic body and a processing method is applied in the field of elastic body processing for gravity sensors, which can solve the problems of low processing quality and low processing accuracy, and achieve the effects of improving clamping stability, improving milling accuracy and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

[0022] The processing method of H6A circular elastic body for sensor provided by the invention comprises the following steps:

[0023] The first step is to prepare a cylindrical steel rod with a diameter of 78mm and a length of 154mm;

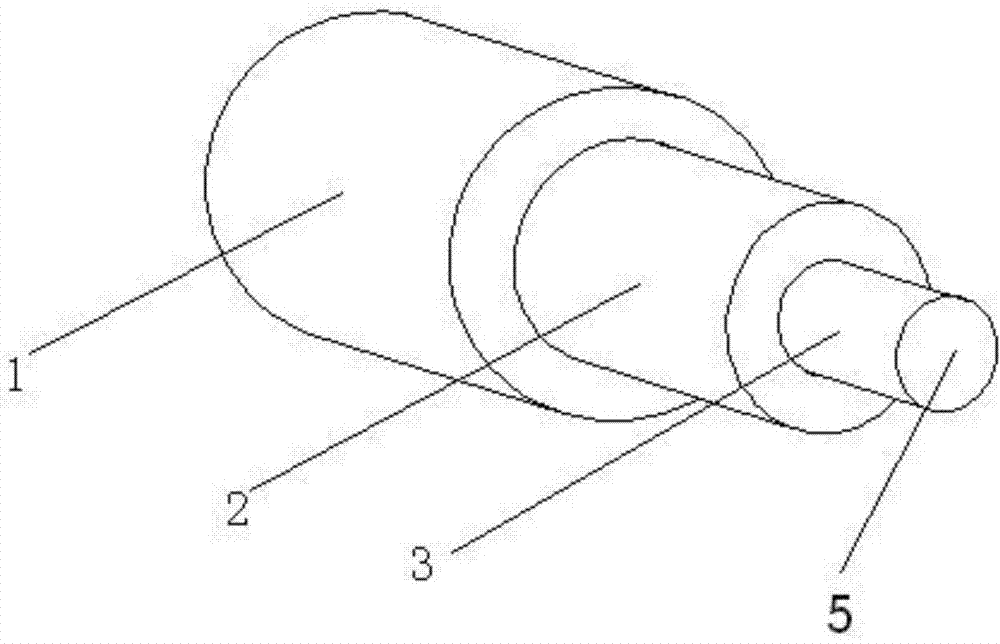

[0024] The second step is to roughly turn the three sections of the outer circle of the steel bar, which are the first outer circle 1, the second outer circle 2 and the third outer circle 3, the diameters are 76mm, 46mm, 33mm, and the axial lengths are 64mm, 30mm, 60mm, and make the roughness of the first end face 4 and the second end face 5 be 3.2μm; then finish turning three sections of the outer circle, so that the diameters of the first outer circle 1, the second outer circle 2, and the third outer circle 3 Respectively 75mm, 45mm, 31.5mm; if figure 1 Shown is the schematic diagram after the completion of the second step;

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com