Circular ring manufacturing tool

A technology of tooling and rings, applied in manufacturing tools, auxiliary devices, wire processing, etc., can solve the problems of single processing size, waste of materials, and low labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

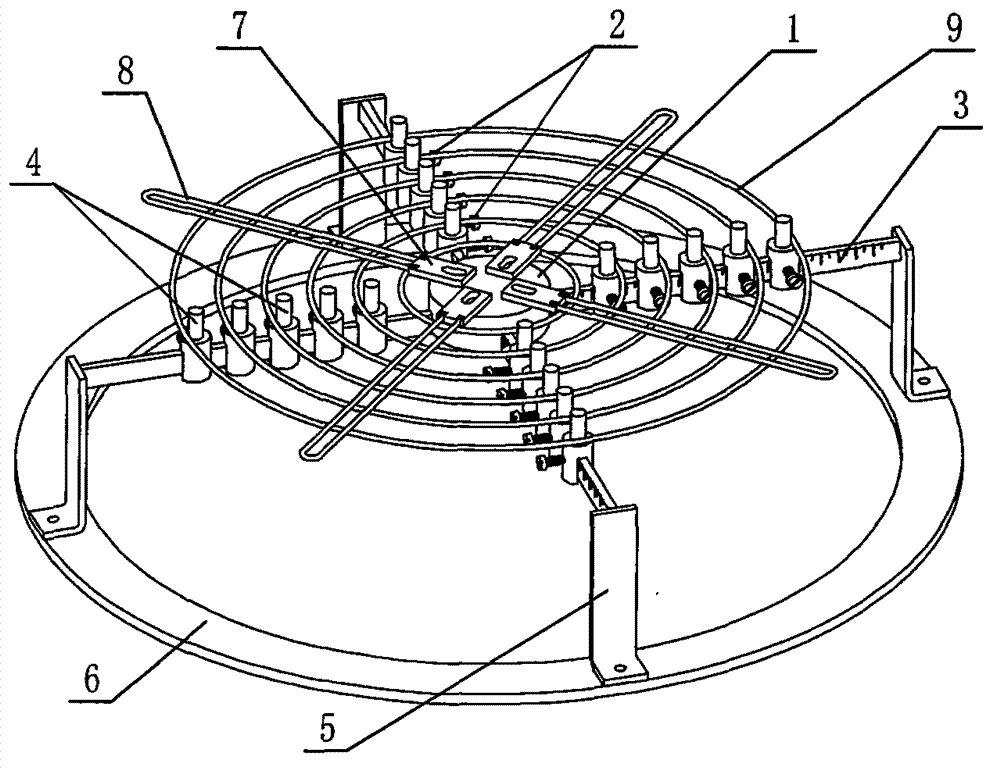

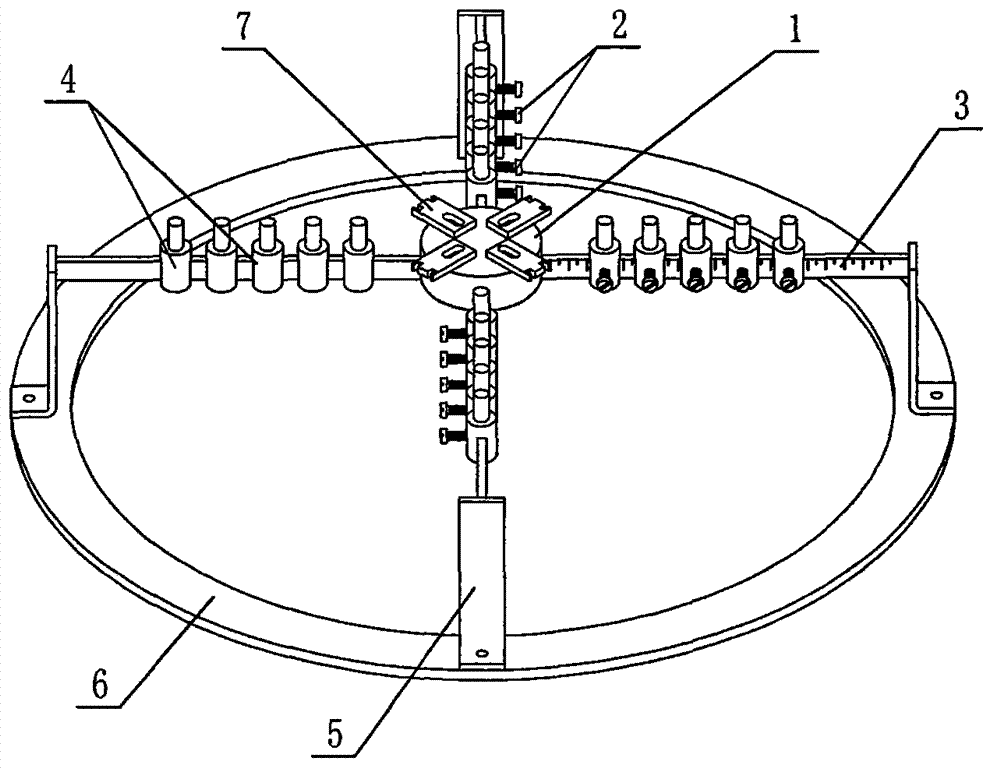

[0010] Such as figure 1 and figure 2 The shown ring manufacturing tooling includes a circular chassis 6, a circular fixed platform 1 is arranged above the axis of the chassis 6, and a plurality of limit blocks 7 are arranged on the fixed platform 1 ring, and each limit block 7 is inserted with a flattening rod 8, and at least three radial support arms 3 are also fixedly installed on the fixed table 1, and the top surface of the support arm 3 is lower than the flattened rod 8. Four radial arms 3 are installed, and a plurality of stoppers 4 are slidably installed on each arm 3, and the stoppers 4 are composed of a sleeve set on the support arm 3 and a stopper arm fixed on the sleeve , the sleeve can slide left and right on the support arm 3, the stop arm can be cylindrical, and its diameter is smaller than the diameter of the sleeve, and each block 4 is equipped with bolts that can lock the block 4 on the support arm 3 2. The bolt 2 shown in the figure is set on the side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com