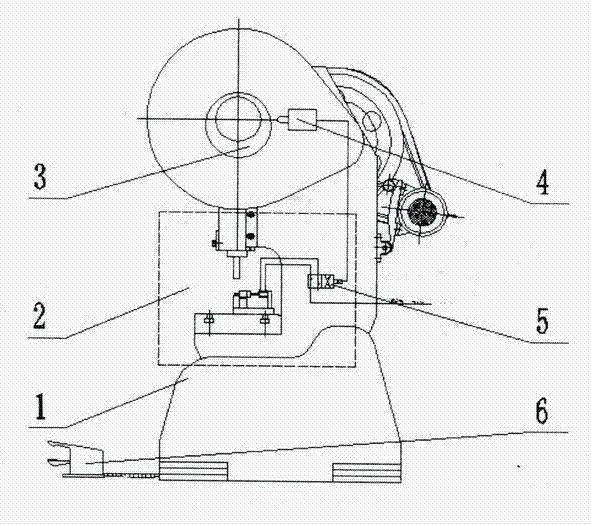

Copper pipe port machining device

A processing device and port technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as difficult to take out, affect production, and prone to failure in combination, so as to save parts cost, save cost, and reduce failure efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

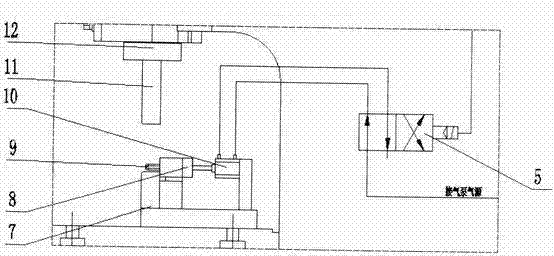

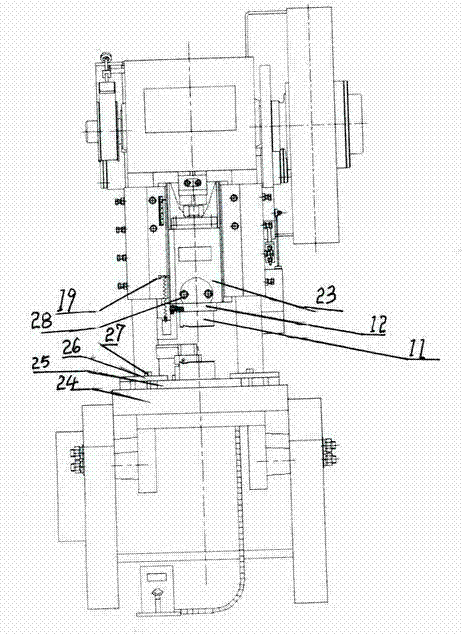

[0009] The embodiment is described in detail in conjunction with the above drawings. The present invention omits the travel switch 4, the solenoid valve 5 and the cylinder 10. The specific embodiments are as follows: the lower die 7 is assembled on the template 25, and the template 25 passes through the mold pressing plate 26 with the pressing plate screw 27 and the punching machine. The table top 24 is fixed, the upper mold 11 is assembled with the mold handle 12, the mold handle is fixed with the punch slide rail 23 through the slider mold handle fixing device 28, the cam 20 is assembled in the cam seat 13, and the cam seat is fixed on the mold handle 12 by the fixing screw 14 One end of the cam extension spring 21 and the cam are fixed by the screw 2, and the other end is fixed on the side of the punch slide rail 23 by the cam extension spring fixing screw 29. One end of the return spring 17 is connected and fixed with the return spring baffle 16, and the other end is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com