Servo control system on solar thin film cell conducting glass magnetic control sputtering device

A servo control system and solar thin film technology, applied in the field of servo control systems, can solve problems such as production stoppage and uneven coating layer, achieve enhanced anti-interference ability, overcome low-speed jitter and position control errors, and improve quality and output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] For further elaborating the technical means and effects that the present invention takes to reach the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to the transmission on the magnetron sputtering equipment of a kind of solar thin film cell conductive glass that proposes according to the present invention The servo control system is described in detail as follows.

[0021] Different embodiments of the present invention will be described in detail below to implement different technical features of the present invention. It should be understood that the units and configurations of the specific embodiments described below are used to simplify the present invention, which are only examples and not limiting scope of the invention.

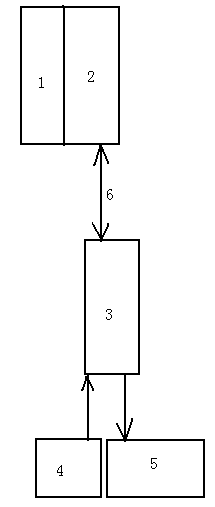

[0022] figure 1 Shown is a schematic diagram of the servo control system on the conductive glass magnetron sputtering equipment for solar thin film cells. The system includes: PLC1, communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com