Loaded power divider

A power divider and coupling cavity technology, which is applied to waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of reduced processing accuracy, high broadband series, and increased volume at the intersection, and achieves high broadband series. Low processing difficulty and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

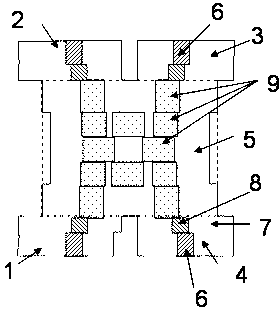

[0025] Such as figure 1 As shown, the loaded power splitter includes a coupling cavity 5, and an input and output terminal connected to the coupling cavity 5, that is, an input terminal 1, an output terminal 2, a coupling terminal 3, and an isolation terminal 4 connected to the coupling cavity 5. The input end 1 and the isolation end 4 are located on the front face of the coupling cavity 5, the coupling end 3 and the output end 2 are located on the rear end face of the coupling cavity 5, and the front end face and the rear end face are two opposite end faces of the coupling cavity. The isolation terminal 4 is located on the right side of the input terminal 1, and the coupling terminal 3 is located on the right side of the output terminal 2. The coupling cavity 5 is provided with columns 9, the columns 9 are arranged in 5 rows along the front-to-back axis of the input end 1, and the columns 9 are arranged in 3 rows along the direction perpendicular to the front-to-back axis of ...

Embodiment 2

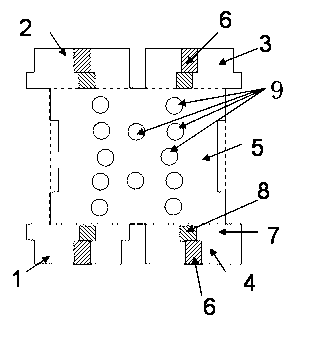

[0032] Such as image 3As shown, the difference from Example 1 is that 12 cylindrical columns are used instead of 12 rectangular columns 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com