Liquid automatic discoloring disguised film device

A power device and film technology, which is applied in the field of color-changing film devices, can solve the problems of long response time, high price, and low cycle times, and achieve the effects of long service life, good camouflage performance, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

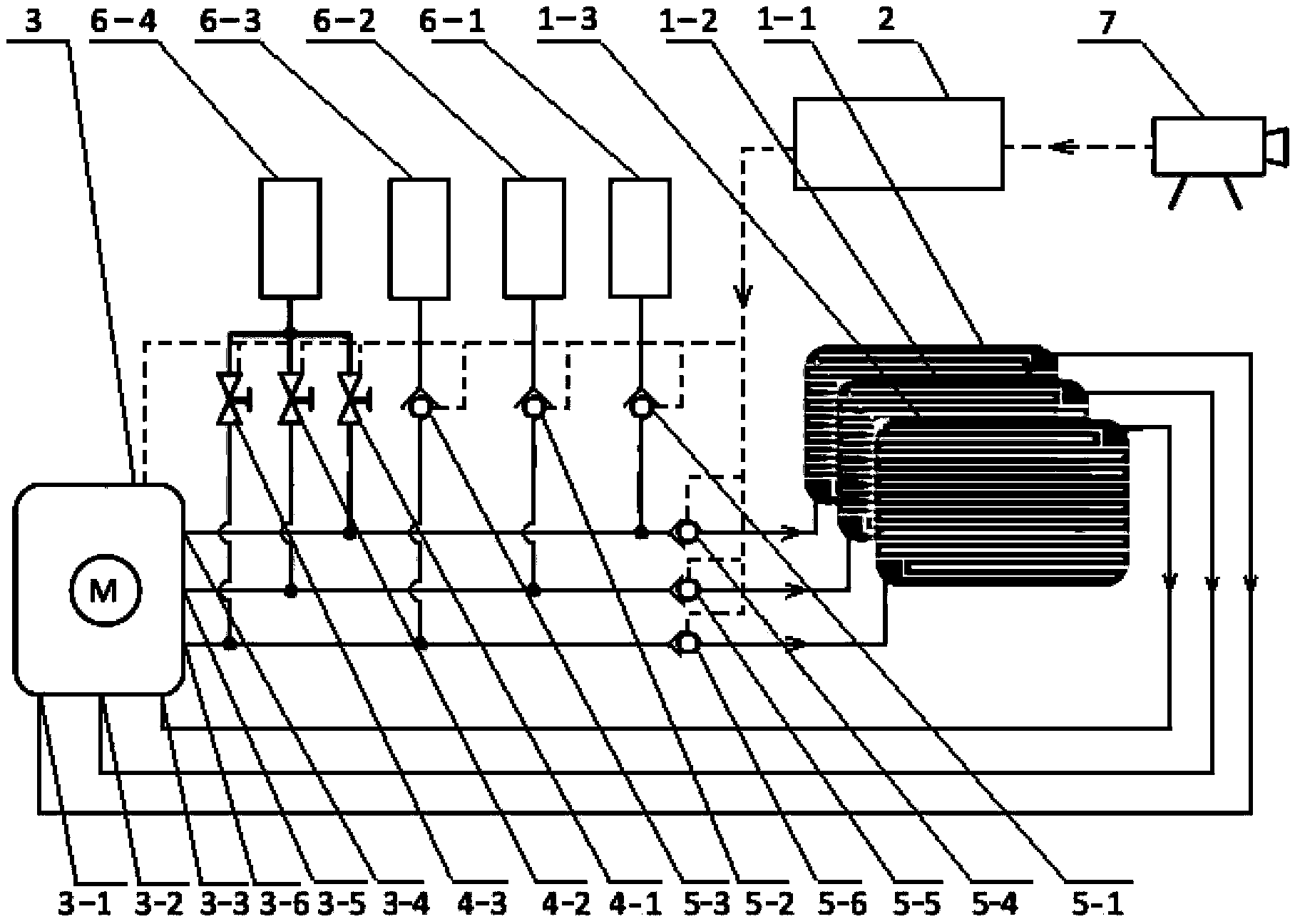

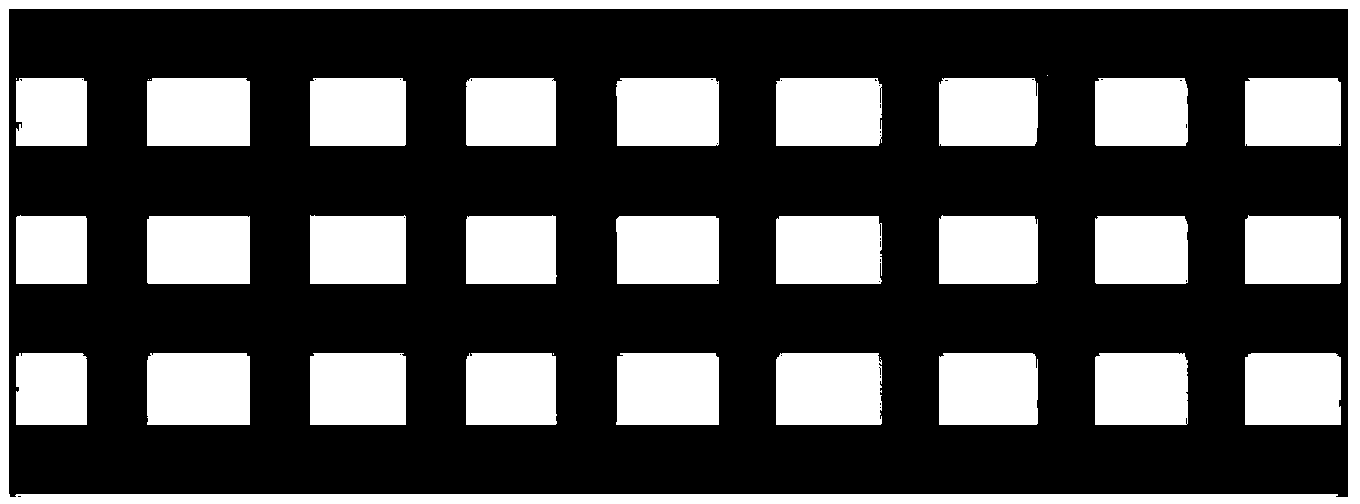

[0013] Embodiment 1: This embodiment is a liquid automatic color-changing camouflage film device, which consists of a multi-layer color-changing channel film, a liquid injection power device 3, a microvalve device, a logic control unit 2, a colored liquid concentration ratio unit and a camera 7 Composition; the multi-layer color-changing flow channel film is sequentially laminated by the first color-changing flow channel film 1-1, the second color-changing flow channel film 1-2 and the third color-changing flow channel film 1-3; The valve device consists of a first control valve 4-1, a second control valve 4-2, a third control valve 4-3, a first controllable check valve 5-1, a second controllable check valve 5-2, a Three controllable one-way valves 5-3, the fourth controllable one-way valve 5-4, the fifth controllable one-way valve 5-5 and the sixth controllable one-way valve 5-6; the colored liquid concentration The proportioning unit consists of the first unit 6-1 containing...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the material of the multilayer color-changing channel film is polydimethylsiloxane, polymethyl methacrylate, glass and polymer resin one or a combination of several of them. Others are the same as in the first embodiment.

specific Embodiment approach 3

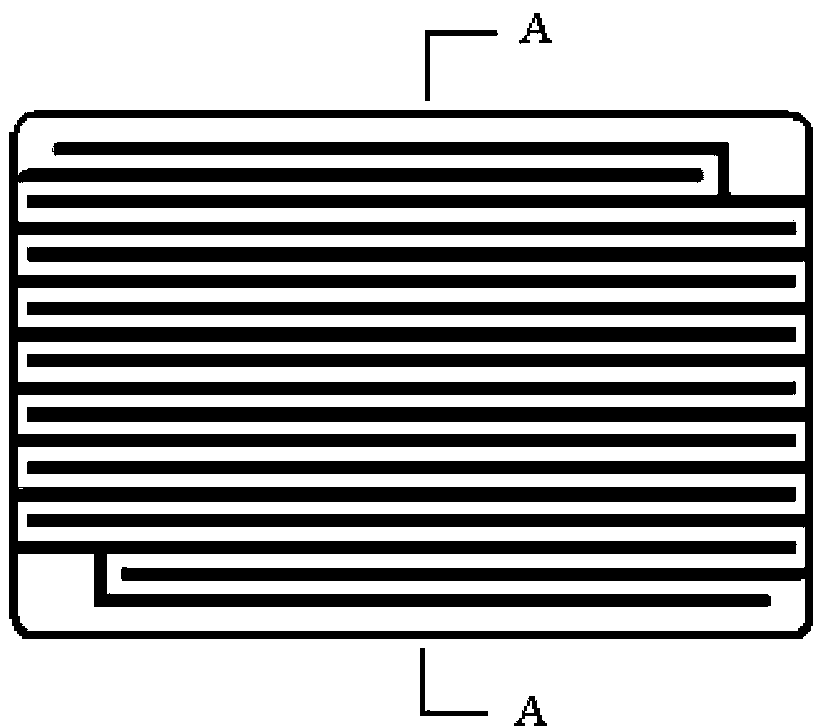

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the flow channels inside the multi-layer color-changing flow channel film are evenly distributed in the film in a labyrinth pattern, and both ends of the flow channels are open. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com