Test system of full gauge drilling bit rock breaking

A test system, drill bit rock-breaking technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as large limitations of extended functions, low degree of automation, and susceptibility to external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

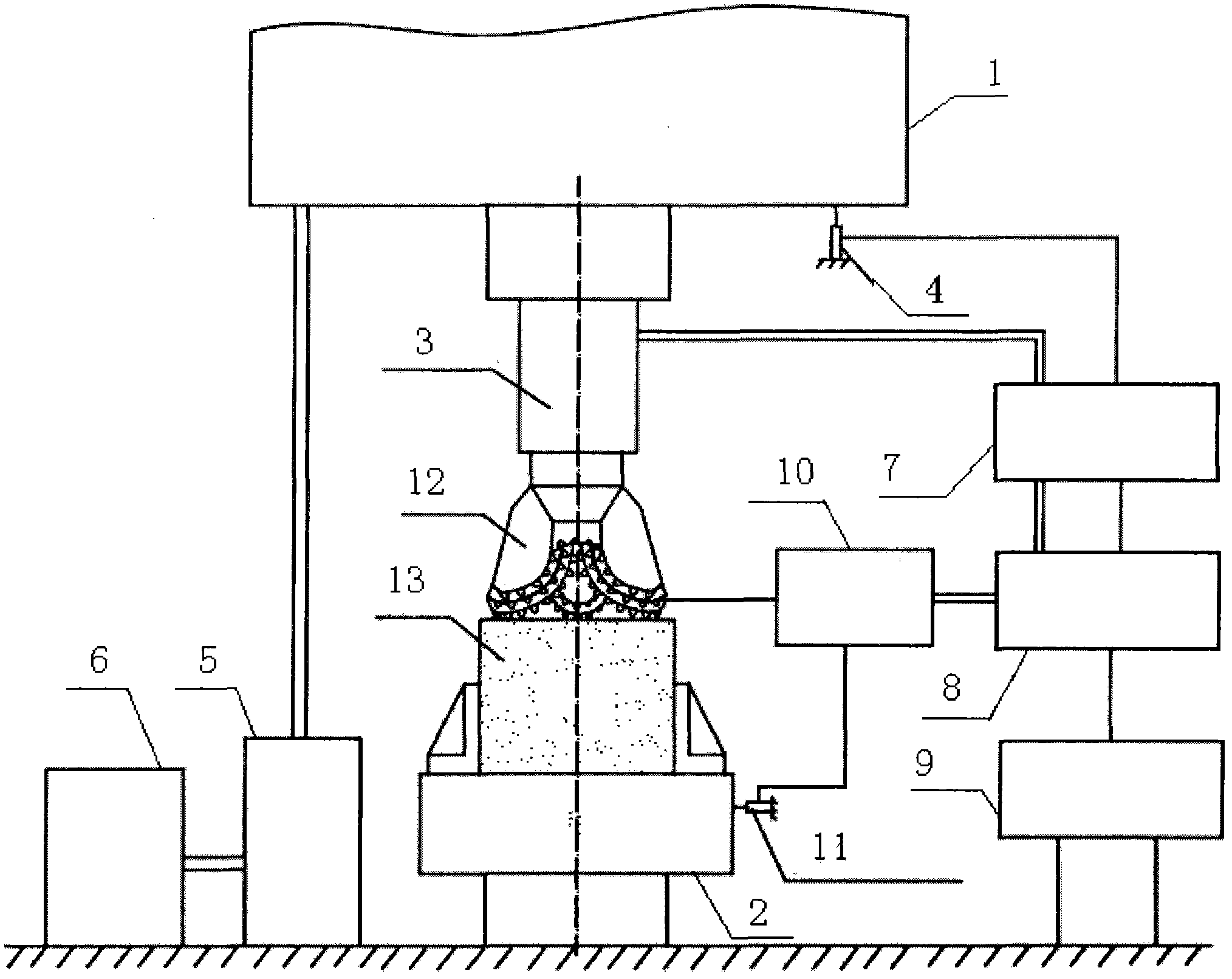

[0022] Such as figure 1 As shown, the full drill bit rock-breaking test system involved in the present invention is mainly composed of a drill bit test stand 1, a lower turntable 2 arranged below the drill bit test stand 1, a measuring joint 3 and a displacement sensor 4 installed on the drill bit test stand 1, The drill test stand 1 is connected with a driving device, and the measuring joint 3 and the displacement sensor 4 are connected with the same measurement and control device.

[0023] The driving device is mainly composed of an oil cylinder 5 connected with the drill test stand 1 and a hydraulic console 6 connected with the oil cylinder 5 .

[0024] The measurement and control device is mainly composed of a dynamic strain gauge 7 connected to the measuring joint 3 and the displacement sensor 4 , a data acquisition box 8 connected to the dynamic strain gauge 7 , and a computer 9 connected to the data acquisition box 8 .

[0025] The data acquisition box 8 is also connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com