Continuous blowdown and recirculating device at bottom of hot water boiler

A hot water boiler and boiler blowdown technology, which is applied in the field of hot water boilers, can solve problems such as poor sewage absorption effect, natural circulation damage, and waste of electric energy, and achieve the effects of preventing furnace tube blockage, high thermal efficiency, and realizing safe and economical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

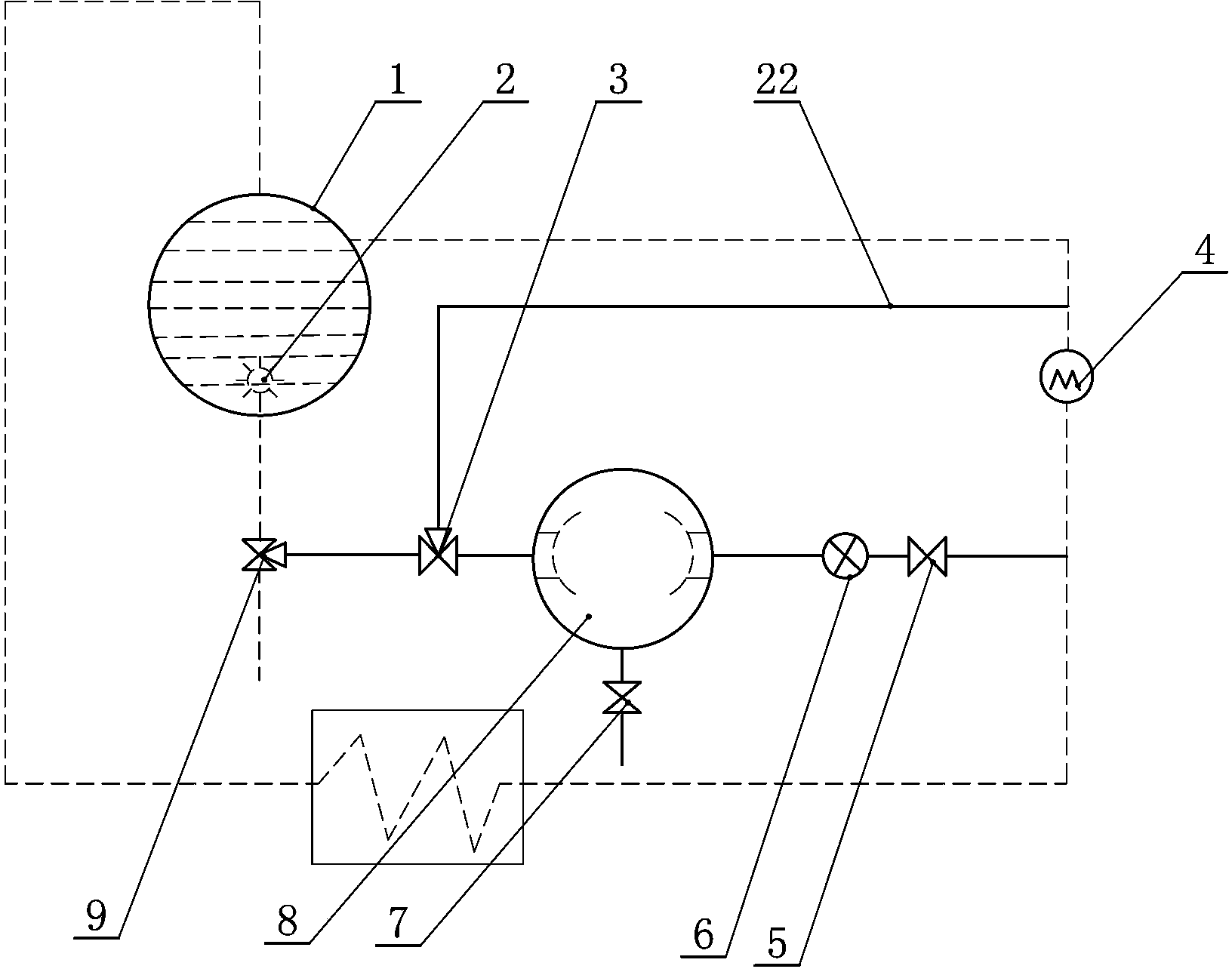

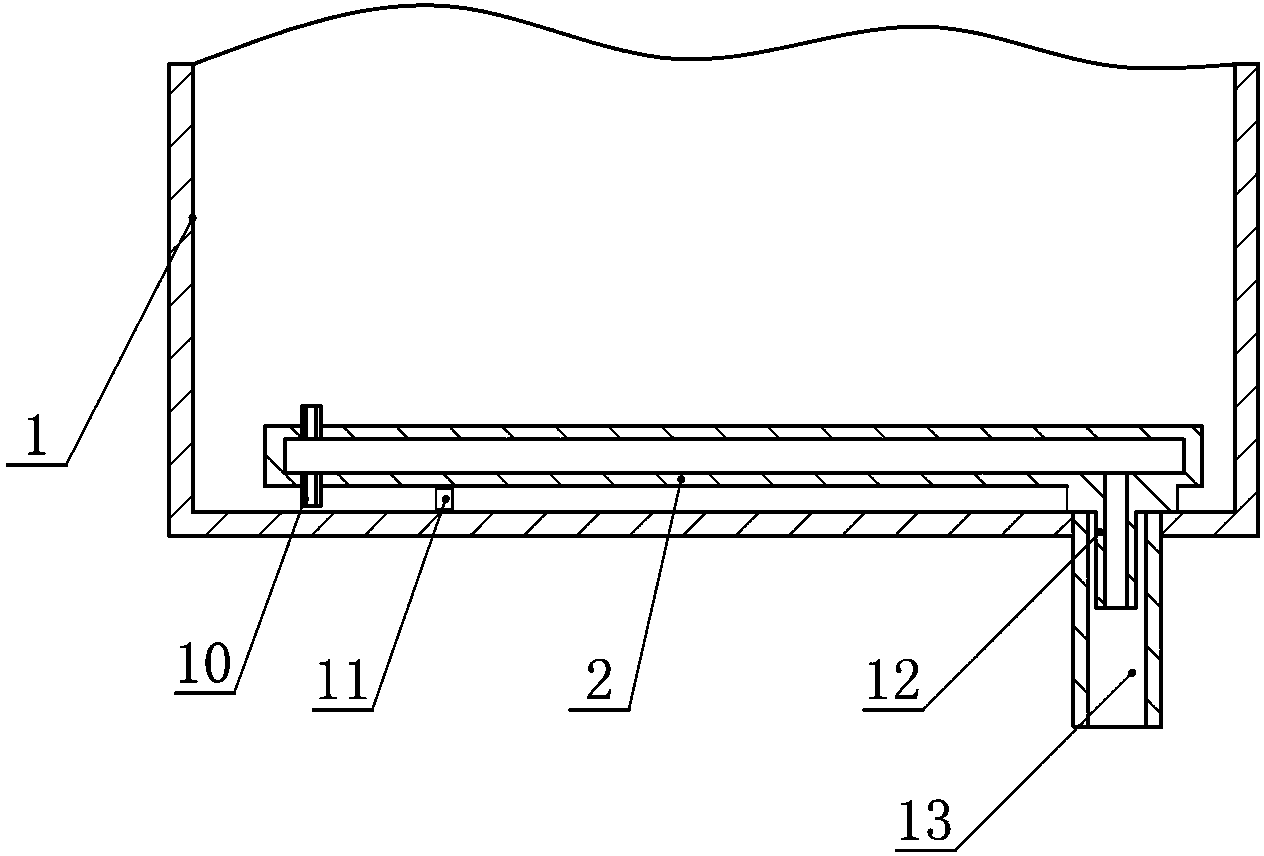

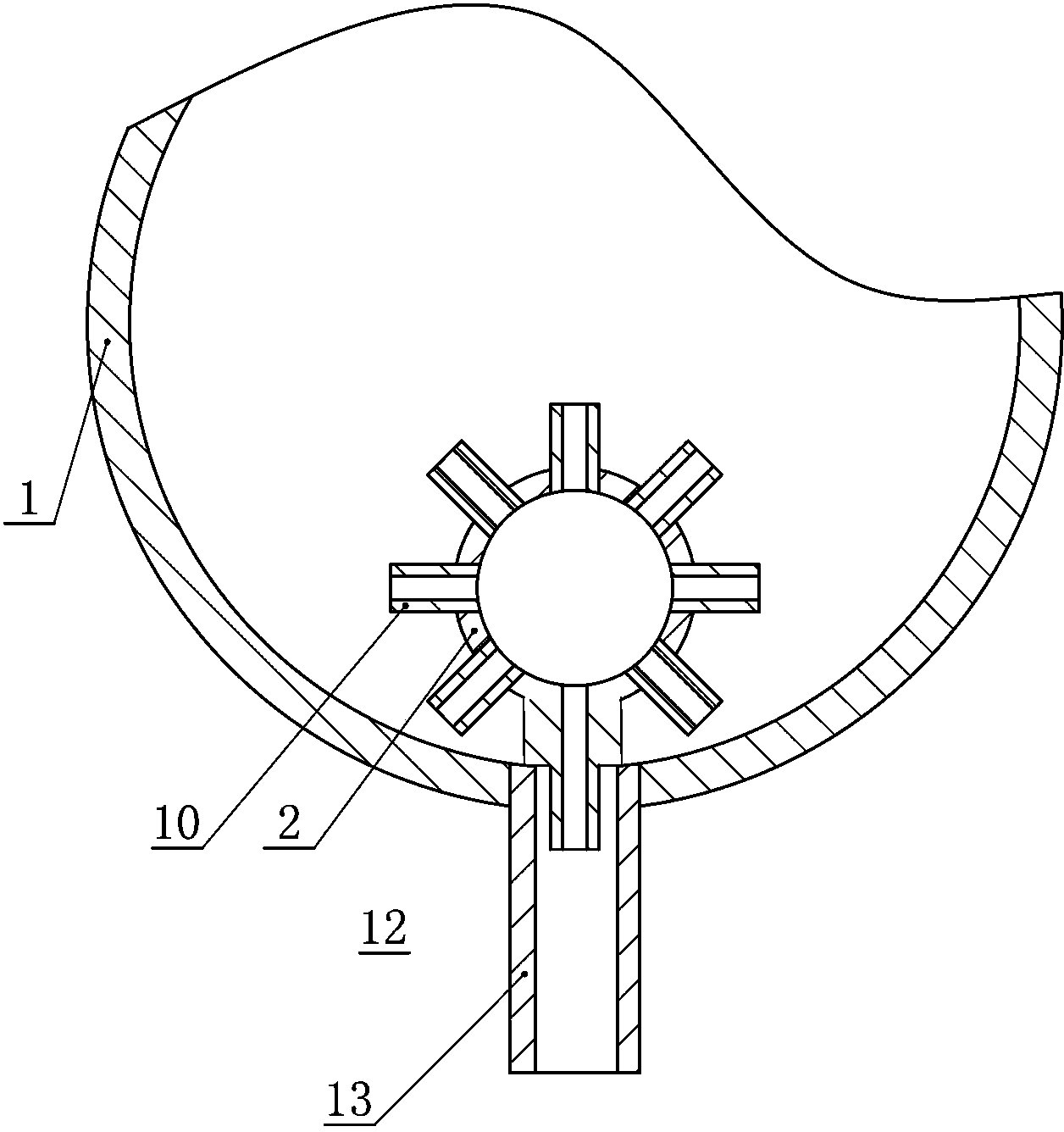

[0018] The present invention as figure 1 , 2 As shown in , 3 and 4, a continuous blowdown recirculation device at the bottom of a hot water boiler, including a boiler 1, is characterized in that: a mace-type sewage suction pipe 2 is provided at the bottom of the boiler 1, and a boiler is provided at the bottom of the boiler 1. The sewage pipe 13, the mace type sewage suction pipe 2 is connected to the boiler sewage pipe 13, the boiler sewage pipe 13 is connected to the continuous row three-way valve 9, and the continuous row three-way valve 9 is connected to the decontamination three-way valve 3 through the pipeline, and the decontamination three-way valve The valve 3 is connected to the spherical decontamination device 8 through the pipeline, and the spherical decontamination device 8 is connected to the flow meter 6, the flow regulating valve 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com