Photocatalyst ecological aluminum floor structure for carbon crystal floor heating supply system

A heating system and photocatalyst technology, applied in the field of aluminum flooring, can solve problems such as difficult to avoid heat loss, unsatisfactory heat preservation effect, long preheating time, etc., achieve good heat preservation effect, reliable connection, and improve thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

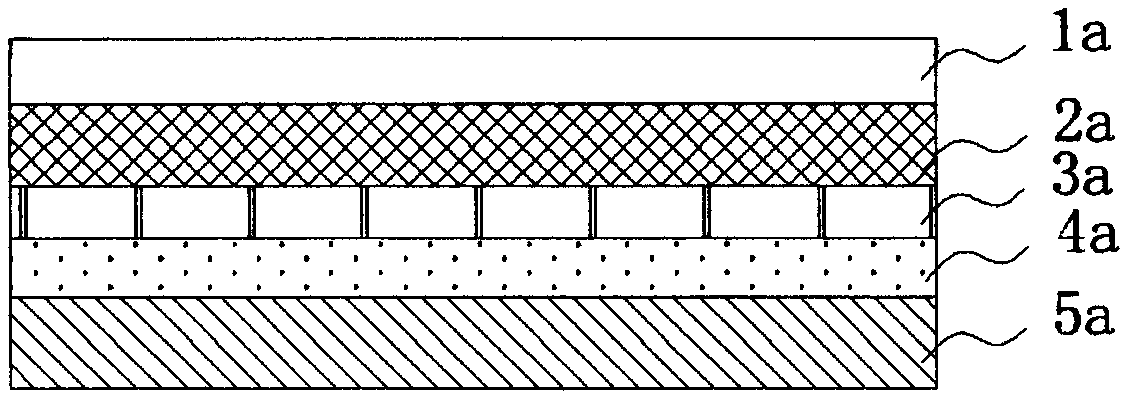

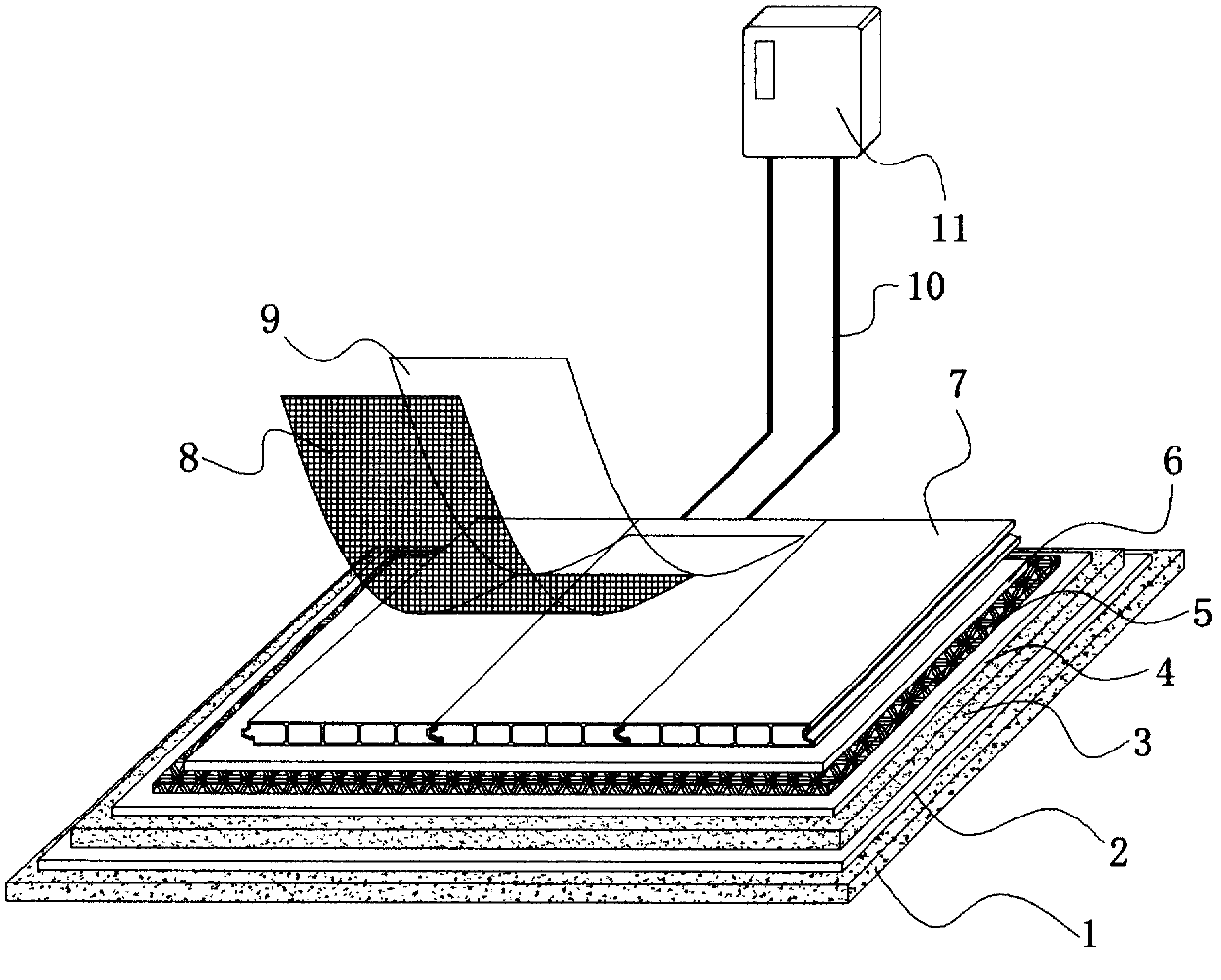

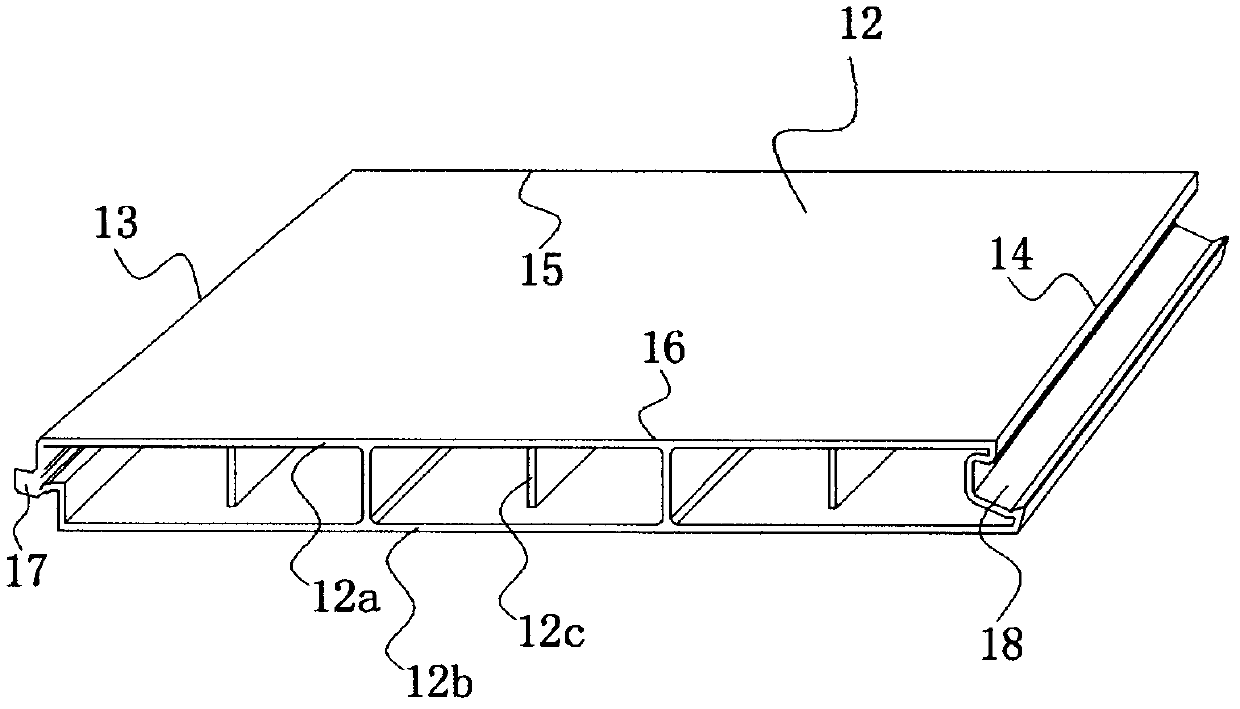

[0024] The carbon crystal heating plate is made of polymer nano-semiconductor material - carbon crystal as the main material, adding far-infrared emitter, and epoxy resin, high temperature and high pressure. After the product is energized, under the excitation of the electric field, the carbon molecules The clusters produce "Brownian motion" and collide with each other, friction generates heat energy, and generates a large amount of infrared radiation. 29% conduction heat and nearly 71% far-infrared radiant heat are generated within tens of seconds of electrification, (the electric energy conversion rate is close to 100% after testing), and the heat energy is transferred to the covering on the surface of the carbon crystal electric heating material. After 2-4 minutes, the heating element It reaches a thermal equilibrium with the insulation material, and radiates directly to the heating space at a constant temperature.

[0025] When manufacturing the above-mentioned carbon crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com