Cooling system control method and device

A technology of cooling system and control method, applied in pump control, liquid variable capacity machinery, reduction of greenhouse gases, etc. The effect of preventing pump overflow, increasing system resistance, and reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

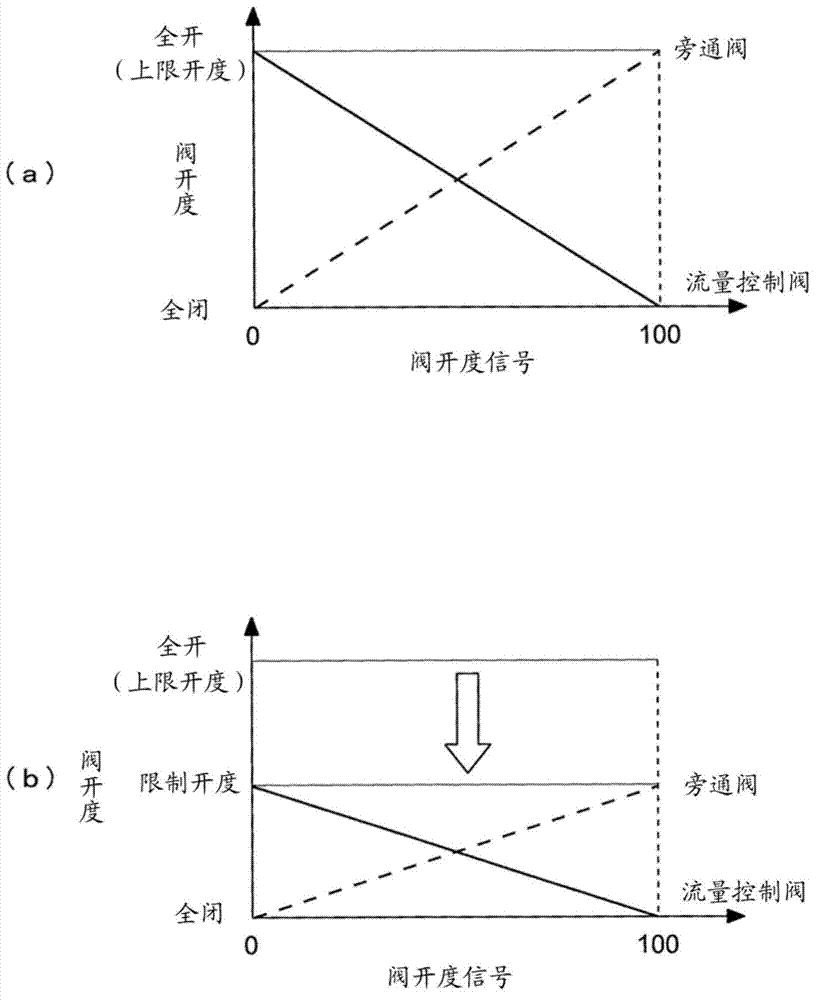

Method used

Image

Examples

Embodiment Construction

[0070] Embodiments of the present invention will be described below with reference to the drawings. However, the dimensions, materials, shapes, and relative arrangements of components described in this embodiment are not limited to specific descriptions, nor are they intended to limit the scope of the present invention thereto, but are merely illustrative examples.

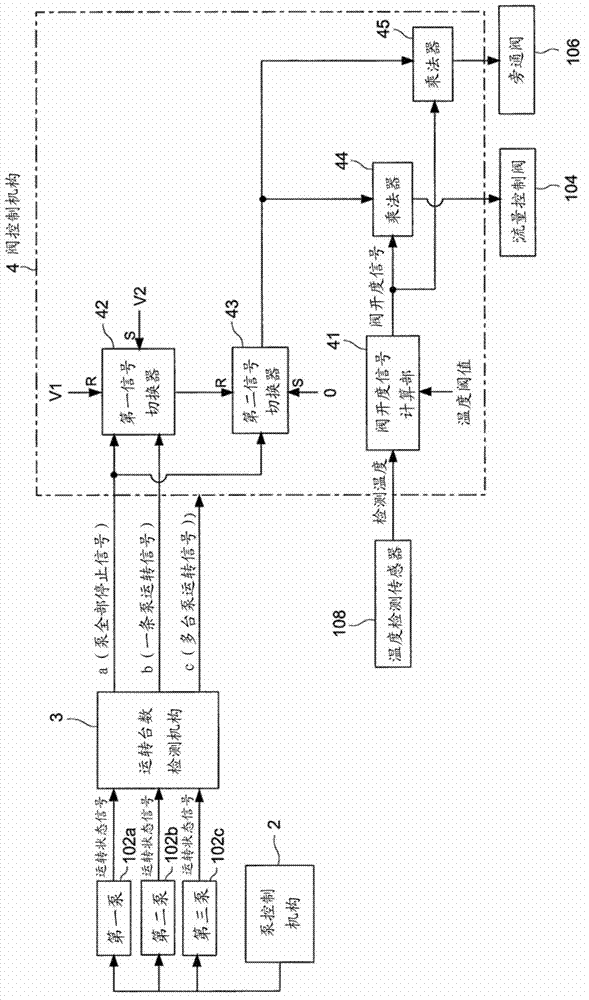

[0071] figure 1 It is a configuration diagram showing the equipment configuration of the cooling system and its control device according to the embodiment of the present invention.

[0072] refer to figure 1 , first, a cooling system to which an embodiment of the present invention is applied will be described. This cooling system 100 is set up for cooling the auxiliary equipment of the nuclear power plant, mainly possesses: the circulation line 101 that makes the cooling water circulate by the closed loop; With respect to the multiple pumps 102a, 102b, 102c that are connected in parallel with the circulation l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com