Pulping method for waste Renminbi

A RMB and pulping technology, which is applied in the field of papermaking and pulping, can solve the problems of pulp fibers that are difficult to disperse, cannot be well utilized, and the smoothness of the paper surface is low, and achieve low cost, stable cooking quality, uniformity and high yield. The effect of high slurry rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

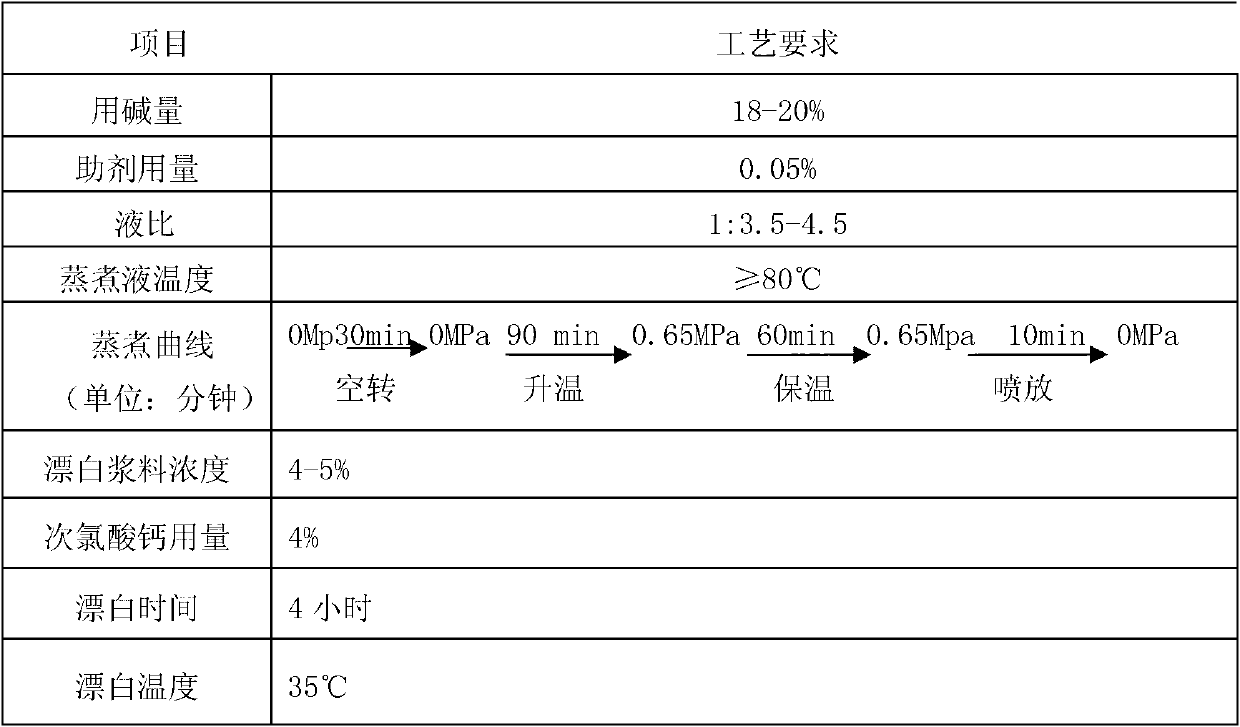

[0021] The invention uses waste RMB as raw material, adopts caustic soda anthraquinone method to make pulp, and selects equipment as steaming balls. Cooking and bleaching process parameters are as follows in the method:

[0022]

[0023] When cooking liquid configuration

[0024] 1. According to the amount of alkali used for cooking, the liquid ratio, and the concentration and volume of the cooking liquid.

[0025] 2. After determining the concentration and volume, use the white liquor produced by alkali recovery and purchased caustic soda in a ratio of 7:3 for preparation.

[0026] 3. The temperature of the cooking liquid must be heated to 80-85°C.

[0027] 4. Add the prepared cooking liquid to the spiral prepreg and stir evenly with the waste RMB before loading.

[0028] 5. Before heating up, it must be idling before heating up, and the temperature can be raised rapidly according to the heating time and steam pressure.

[0029] 6. After bleaching, the whiteness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com