Matte discoloring long-wool printing treatment agent for synthetic leather and preparation method thereof

A treatment agent and synthetic leather technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of synthetic leather bottom layer dissolution, viscosity, stability, poor hand feel, and synthetic leather hand feel, etc., to achieve strong leather feel, Good discoloration effect, good discoloration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

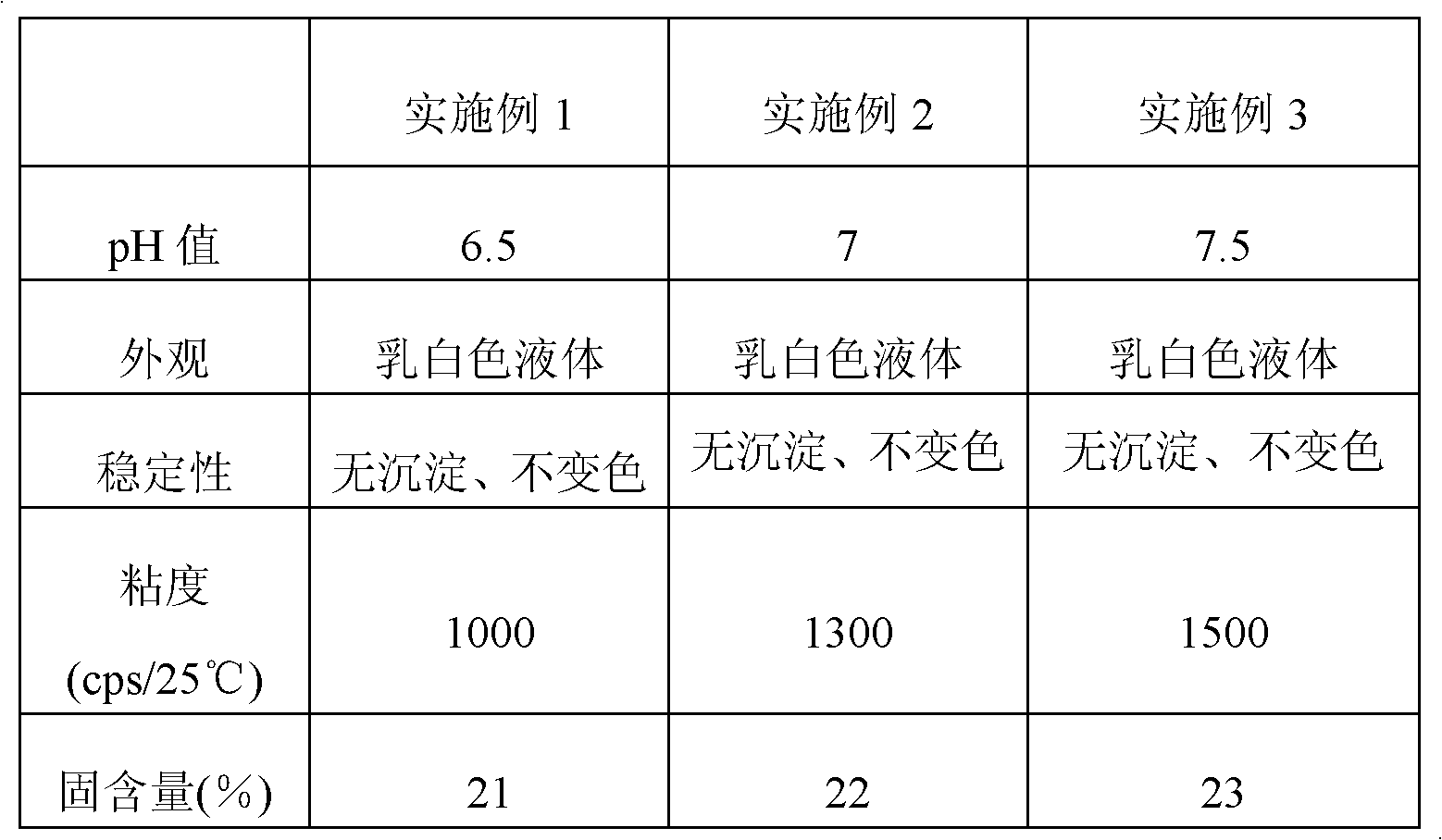

Embodiment 1

[0023] A matte color-changing long-hair printing treatment agent for synthetic leather, consisting of 27 parts by weight of modified polyurethane resin, 20 parts by weight of butyl ester, 27 parts by weight of toluene, 10 parts by weight of acetone, and 2 parts by weight of silicon dioxide Matting powder, 1 part by weight of modified siloxane, 1 part by weight of methoxy silicone oil, 1 part by weight of amino silicone oil, 3 parts by weight of polyurethane nanofiber, and 8 parts by weight of polytetrafluoroethylene discoloration wax powder.

[0024] At normal temperature and pressure, put 20 parts by weight of modified polyurethane resin, 20 parts by weight of butyl ester, 27 parts by weight of toluene, 10 parts by weight of acetone, and 2 parts by weight of silica matting powder into a 1L reactor , filtered after stirring at room temperature for 30 minutes; in the mixture obtained above, add 1 weight part of modified siloxane, 1 weight part of methoxy silicone oil, 1 weight p...

Embodiment 2

[0027] A matte color-changing long-hair printing treatment agent for synthetic leather, consisting of 25 parts by weight of modified polyurethane resin, 15 parts by weight of butyl ester, 25 parts by weight of toluene, 8 parts by weight of acetone, and 1 part by weight of silicon dioxide Matting powder, 0.5 parts by weight of modified siloxane, 0.5 parts by weight of methoxy silicone oil, 0.5 parts by weight of amino silicone oil, 0.5 parts by weight of polyurethane nanofiber, and 10 parts by weight of polytetrafluoroethylene discoloration wax powder.

[0028] At normal temperature and pressure, put 15 parts by weight of modified polyurethane resin, 15 parts by weight of butyl ester, 25 parts by weight of toluene, 8 parts by weight of acetone, and 1 part by weight of silica matting powder into a 1L reactor , filtered after stirring at room temperature for 30 minutes; in the mixture obtained above, add 0.5 parts by weight of modified siloxane, 0.5 parts by weight of methoxy sili...

Embodiment 3

[0031] A matte color-changing long-hair printing treatment agent for synthetic leather, consisting of 35 parts by weight of modified polyurethane resin, 18 parts by weight of butyl ester, 30 parts by weight of toluene, 9 parts by weight of acetone, and 1.5 parts by weight of silicon dioxide Matting powder, 0.8 parts by weight of modified siloxane, 0.8 parts by weight of methoxy silicone oil, 0.8 parts by weight of amino silicone oil, 2.5 parts by weight of polyurethane nanofiber, and 9 parts by weight of polytetrafluoroethylene discoloration wax powder.

[0032] At normal temperature and pressure, put 25 parts by weight of modified polyurethane resin, 18 parts by weight of butyl ester, 30 parts by weight of toluene, 9 parts by weight of acetone, and 1.5 parts by weight of silica matting powder into a 1L reactor , filtered after stirring at room temperature for 30 minutes; in the mixture obtained above, add 0.8 parts by weight of modified siloxane, 0.8 parts by weight of methoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com