Adsorbent, preparation method and application thereof

A technology of adsorbent and solvent, applied in the field of adsorbent and its preparation, can solve the problems of difficult regeneration, low adsorption capacity, non-selectivity, etc., and achieve the effect of fast adsorption speed, large adsorption capacity and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of adsorbent Cu-TATAB nanocomplex:

[0025] Weigh 194.4mg 4,4',4''-s-triazine-1,3,5-three-p-aminobenzoic acid and 483.2mg Cu(NO 3 ) 2 ·3H 2 O was dissolved in 10mL N,N-dimethylformamide, stirred for 6min, then 0.2mL of 30% hydrogen peroxide was added dropwise, stirred for 8min, and stood at room temperature for 12h to obtain light green powdery adsorbent Cu-TATAB nanocomplexes.

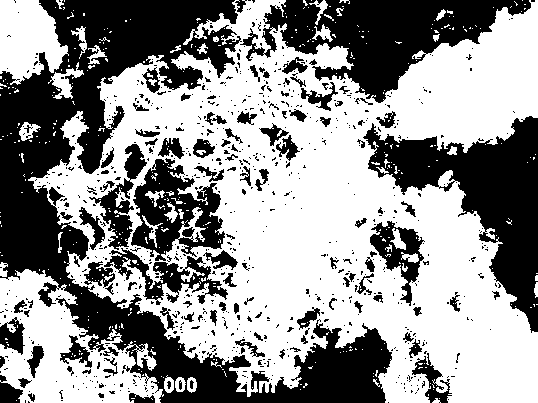

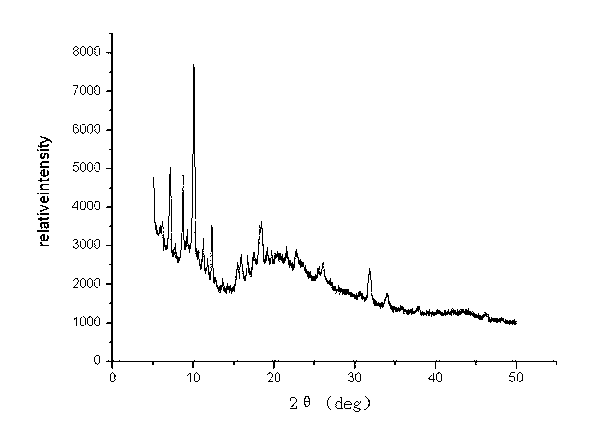

[0026] figure 1 The scanning electron microscope image of the adsorbent prepared for this example is a network structure composed of fibers with an average particle size of 196 nm. figure 2 The powder X-ray diffraction spectrum of the adsorbent Cu-TATAB nanocomplex prepared for this example, the diffraction peaks in the spectrum correspond to the diffraction data of Cu-TATAB.

Embodiment 2

[0028] Preparation of adsorbent Cu-TATAB nanocomplex:

[0029] Weigh 243.2mg 4,4',4''-s-triazine-1,3,5-three-p-aminobenzoic acid and 241.6mg Cu(NO 3 ) 2 ·3H 2 O was dissolved in 10mL N,N-dimethylformamide, stirred for 5min, then 0.2mL of 30% hydrogen peroxide was added dropwise, stirred for 10min, and stood at room temperature for 12h to obtain light green powder adsorbent Cu-TATAB nanocomplexes.

Embodiment 3

[0031] Preparation of adsorbent Cu-TATAB nanocomplex:

[0032] Weigh 194.4mg 4,4',4''-s-triazine-1,3,5-three-p-aminobenzoic acid and 579.8mg Cu(NO 3 ) 2 ·3H 2 O was dissolved in 10mL N,N-dimethylformamide, stirred for 10min, then 0.2mL of 30% hydrogen peroxide was added dropwise, stirred for 5min, and stood at room temperature for 12h to obtain light green powdery adsorbent Cu-TATAB nanocomplexes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com