Template-free preparation method of polymer hollow colloidal sphere

A technology of polymer and colloid spheres, applied in microsphere preparation, microcapsule preparation, chemical recycling, etc., can solve the problems of increased production cost of templates, limited versatility, irregular shape of hollow particles and wide size distribution, etc. Narrow size distribution, saving raw materials and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

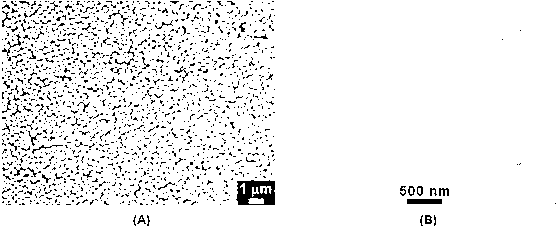

[0031] 0.40 gram of copper acetate monohydrate was dissolved in 40 milliliters of water to obtain a solution with a concentration of 0.05 mol / liter, which was then added to a 250 milliliter stainless steel reactor lined with polytetrafluoroethylene; 160 milliliters of 0.020 mol / liter An aqueous solution of o-methoxyaniline was added to the reaction kettle. After sealing, react at a constant temperature of 150 oC for 7 hours. After cooling to room temperature, centrifuge the colloid solution obtained in the reactor (3000 rpm), wash with ethanol or acetone for 3 times, and disperse in water to obtain Hollow poly-o-methoxyaniline colloidal spheres, the scanning electron microscope (SEM) and transmission electron microscope (TEM) photos of the hollow poly-o-methoxyaniline colloidal spheres prepared in this example are as follows figure 1 As shown in (A) and (B), it can be seen from the figure that the particle size of the hollow poly-o-methoxyaniline colloidal spheres is 200–4...

Embodiment 2

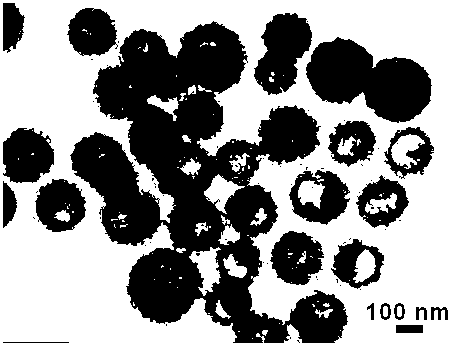

[0034]0.60 grams of copper acetate monohydrate were dissolved in 40 milliliters of water to obtain a solution with a concentration of 0.075 mol / liter, which was then added to a 300 milliliter stainless steel reactor lined with polytetrafluoroethylene; 160 milliliters of 0.025 mol / liter An aqueous solution of o-methoxyaniline was added to the reaction kettle. After sealing, react at a constant temperature at 180 oC for 10 hours. After cooling to room temperature, centrifuge the colloid solution obtained in the reactor (3000 rpm), wash with ethanol or acetone for 3 times, and disperse in water to obtain Such as image 3 Hollow poly-o-methoxyaniline colloidal spheres with a particle size of 200–400 nm and an average cavity volume of 10% are shown.

Embodiment 3

[0036] 0.40 gram of copper acetate monohydrate was dissolved in 40 milliliters of water to obtain a solution with a concentration of 0.05 mol / liter, which was then added to a 250 milliliter stainless steel reactor lined with polytetrafluoroethylene; 160 milliliters of 0.025 mol / liter An aqueous solution of o-methoxyaniline was added to the reaction kettle. After sealing, react at a constant temperature at 180 oC for 12 hours. After cooling to room temperature, centrifuge the colloid solution obtained in the reactor (3000 rpm), wash with ethanol or acetone for 3 times, and disperse in water to obtain Such as Figure 4 Hollow poly-o-methoxyaniline colloidal spheres with a particle size of 200–420 nm and an average cavity volume of 2% are shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com