Preparation method of natural preservative regarding Chinese pear-leaved crabapple leaves as raw material and application thereof

A technology of natural preservatives and main raw materials, applied in applications, preservation of meat/fish with chemicals, food science, etc., can solve the problems of sodium benzoate dosage and use range limitations, and achieve low production cost, good inhibitory effect, and enhanced The effect of antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

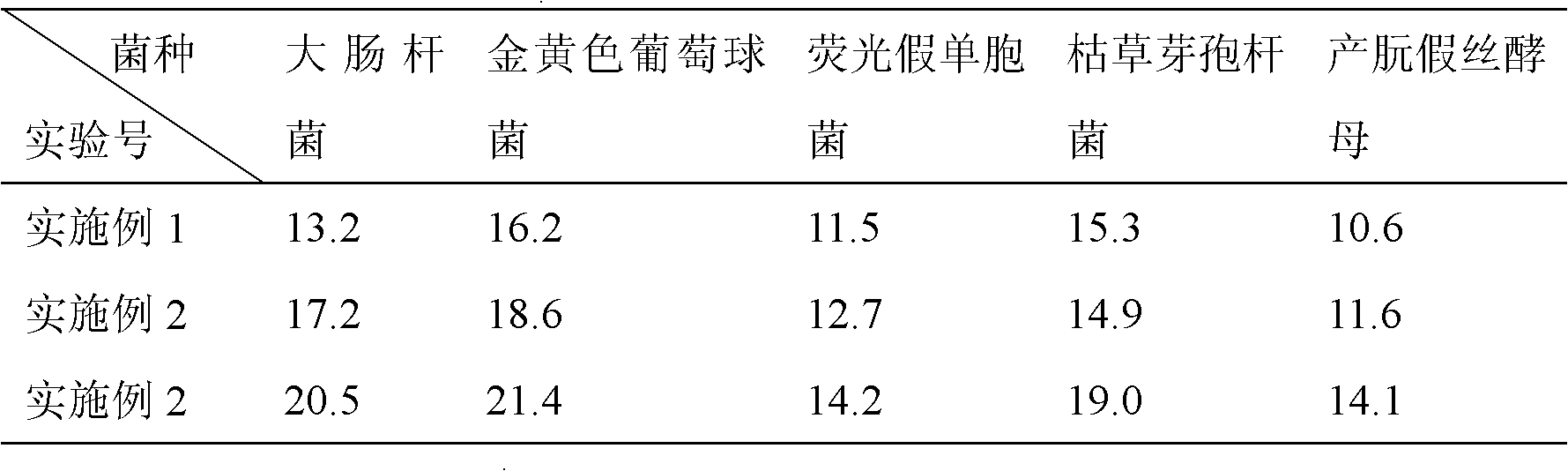

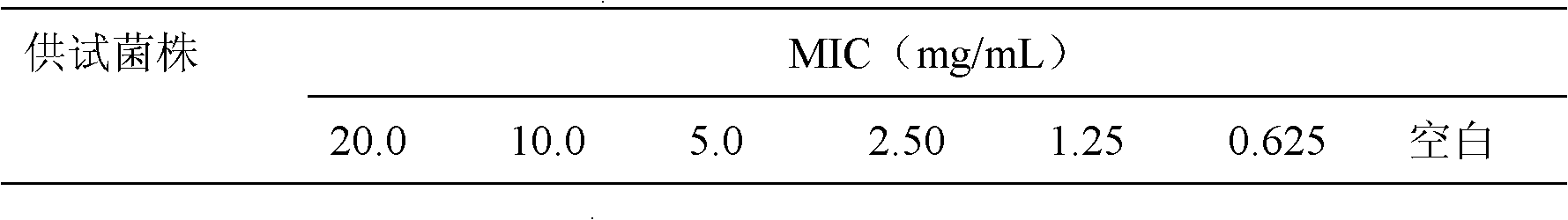

Embodiment 1

[0013] Weigh 1 portion of Linopodium leaves, clean them, put them in a drying oven at 40°C, and dry them to a moisture content of 15%, crush them and pass through a 60-mesh sieve; add 20 times the mass of Linopodium leaves powder with a percentage concentration of 60% Ethanol, heated and refluxed twice at 50°C for 5 hours each time, collected the reflux liquid twice, combined, filtered, transferred to a rotary evaporator and concentrated to 0.4g original drug / mL, and the concentrated solution was filtered through a microporous membrane or centrifuged ( 10000r / min, 10min) upper LSA-10 macroporous resin column, the mass ratio of Linopodium leaf powder and macroporous resin is 1: 1, the ratio of resin column diameter to height is 1: 4, upper column flow rate 1BV / h; Elute 5BV / h, the elution flow rate is 1BV / h, discard the water eluent; then elute with 60% ethanol, the elution flow rate is 1BV / h, collect the ethanol eluate, and use vacuum drying to remove ethanol. Obtain solid leaf...

Embodiment 2

[0015] Weigh 1 portion of Linopodium leaves, clean them, put them in a drying oven at 40°C, and dry them to a moisture content of 16%, crush them and pass through a 60-mesh sieve; add 25 times the mass of ethanol with a concentration of 75% to the powder of Linopodium leaves , refluxed 3 times at 50°C, 3 hours each time, collected reflux liquid for 3 times, combined, filtered, transferred to a rotary evaporator and concentrated to 0.6g original drug / mL, and the concentrated solution was filtered through a microporous membrane or centrifuged (10000r / min, 10min) on the LSA-10 macroporous resin column, the mass ratio of Linopodium leaf powder to macroporous resin is 1:2, the ratio of resin column diameter to height is 1:6, and the column loading speed is 3BV / h; water elution 8BV, the elution rate is 2BV, and the water eluent is discarded; then eluted with ethanol with a percentage concentration of 75%, the elution flow rate is 2BV / h, the ethanol eluate is collected, and the ethan...

Embodiment 3

[0017] Weigh 1 portion of Linopodium leaves, clean them, put them in a drying oven at 40°C, and dry them to a moisture content of 18%, crush them and pass through a 60-mesh sieve; add 30 times the mass of ethanol with a concentration of 95% to the powder of Linopodium leaves , refluxed 4 times at 50°C, 2 hours each time, collected the reflux liquid for 4 times, combined, filtered, transferred to a rotary evaporator and concentrated to 1.0g of the original drug / mL, and the concentrated solution was filtered through a microporous membrane or centrifuged (10000r / min, 10min) on the LSA-10 macroporous resin column, the mass ratio of Linopodium leaf powder to macroporous resin is 1:4, the ratio of resin column diameter to height is 1:8, and the column loading speed is 5BV / h; water elution 10BV, the elution rate is 3BV, and the water eluent is discarded; and then eluted with ethanol with a percentage concentration of 95%, the elution flow rate is 3BV / h, the ethanol eluate is collecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com