Device for adsorbing and emitting carbon dioxide

一种二氧化碳、吸附解吸的技术,应用在碳酸盐/酸式碳酸盐的制备、化学仪器和方法、无机化学等方向,能够解决不能兼顾吸附脱附性能和低能量消耗等问题,达到优异吸附脱附性能、能量消耗少、高吸附能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

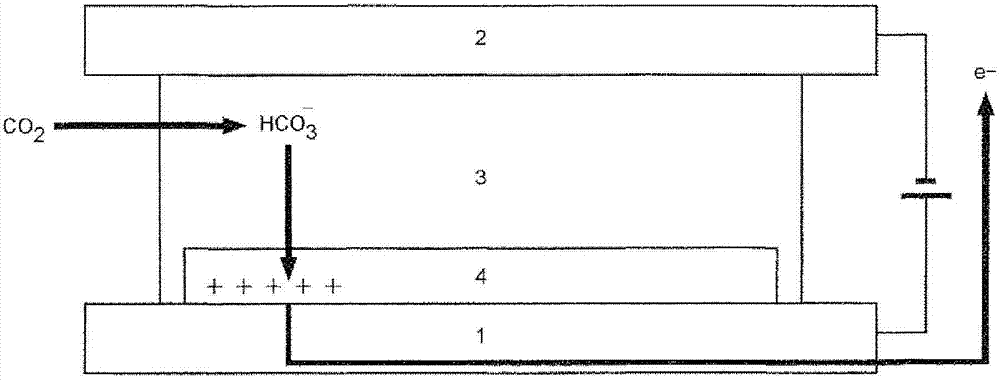

[0117] A conductive glass substrate (manufactured by Asahi Glass Co., Ltd., 10 Ω / □) having a thickness of 1 mm, a length of 21 mm, and a width of 24 mm having a fluorine-doped tin oxide film was prepared. This fluorine-doped tin oxide film was used as electrode 1 . Polyaniline of 1 μm was deposited on the substrate 1 as the porous body 4 using an electrochemical oxidation method (electrolytic polymerization method). On the other hand, a conductive glass substrate (manufactured by Asahi Glass Co., Ltd., 10Ω / □) having a thickness of 1 mm, a length of 21 mm, and a width of 24 mm having a fluorine-doped tin oxide film was prepared, and the fluorine-doped tin oxide film was sputtered. Platinum is deposited on it, and this is used as the electrode 2. The porous body 4 and the electrode 2 were arranged to face each other, and a hot-melt adhesive (manufactured by Dupont, Bynel) with a width of 1 mm and a thickness of 50 μm was interposed between the outer edge portions thereof. By a...

Embodiment 2

[0119] In Example 2, only the structure of the porous body 4 is different from that of Example 1, and the other structures are the same as those of Example 1.

[0120] The porous body 4 was produced by the following method.

[0121] Electrolytic manganese dioxide (MnO) heat-treated at 400°C 2 , positive electrode active material), acetylene black (conductive agent), polyethylene oxide (viscosity average molecular weight 100,000, manufactured by Sigma-Aldrich Corporation) and LiN (CF 3 SO 2 ) 2 Dissolve or disperse in acetonitrile and mix uniformly to prepare a paste-like positive electrode mixture. Here, to make MnO 2 : Acetylene black: polymer electrolyte = 70% by mass: 20% by mass: 10% by mass. In addition, the mass of the polymer electrolyte is a mass in terms of solid content. The obtained paste-like positive electrode mixture was coated on an electrode, dried at 1200° C. for 24 hours, and then rolled by a roll press to produce a porous body 4 . The carbon dioxide a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com