Meter gauge bogie

A bogie and meter-gauge technology, applied in the field of bogies, can solve the problems that the core components of trailer bogies-frames cannot be completely interchanged, high design and manufacturing costs, and fast wheel wear, so as to save operation and maintenance costs and improve Service life, effect of preventing heat influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

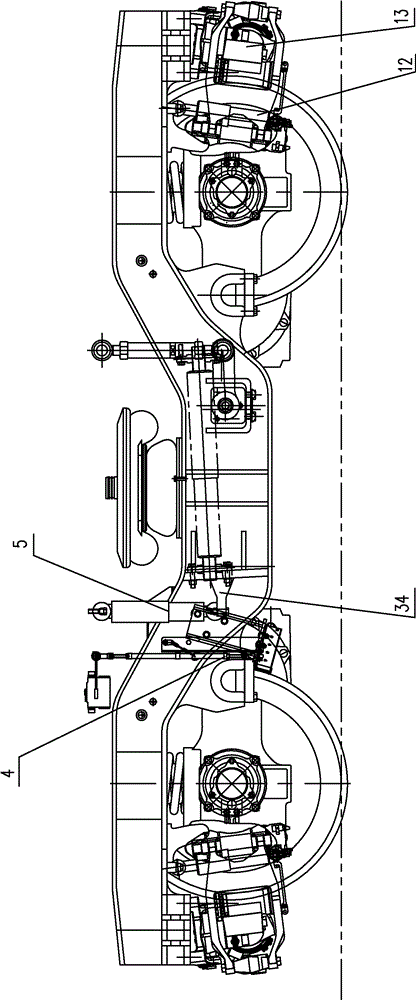

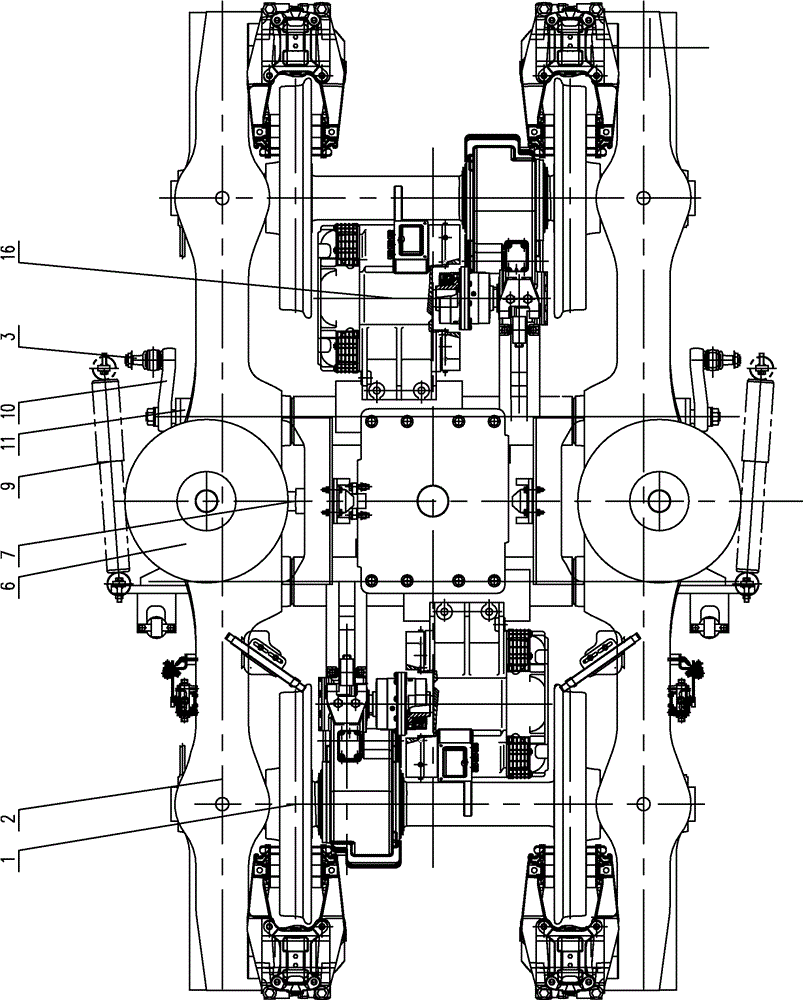

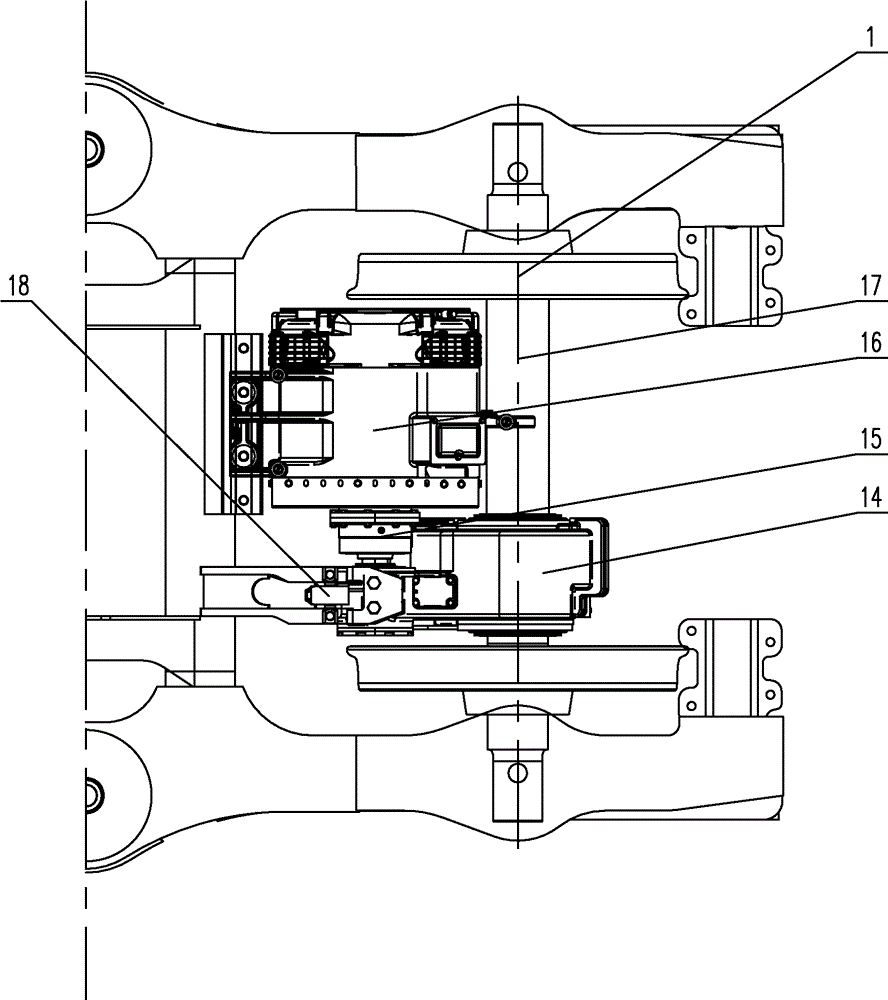

[0036] Such as Figure 1-7 As shown, the frame 2 adopts an "H"-shaped structure, which is welded by low-alloy high-strength steel plates, seamless steel pipes and castings. Wheel to axle box 1 adopts integral rolling steel wheel, alloy steel axle, cast steel axle box. The driving device of the disc-brake meter-gauge bogie is rigidly suspended on the frame 2 by the motor 16, and the toothed coupling 15 is installed between the motor 16 and the gear box 14, and the driving torque is transmitted to the Gear box 14, one end of the gear box 14 is suspended on the axle 17 of the wheel-to-axle box 1, and the other end is suspended on the frame 2 through the gear box suspender 18.

[0037] The basic braking of the meter-gauge bogie adopts the form of wheel disc braking. There is a notch 32 near the brake disc 24 in the gear box 14. The brake disc 24 is connected to the wheel 19 through the connecting bolt 21. The brake pads 20 are installed on the unit brake. On the clamp 22 , the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com