Interface coupling system between accelerator and windowless spallation target and liquid level stabilization method

A technology of interface coupling and accelerator, applied in DC voltage accelerators, targets for generating nuclear reactions, accelerators, etc., can solve problems such as inability to satisfy stable vertical flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

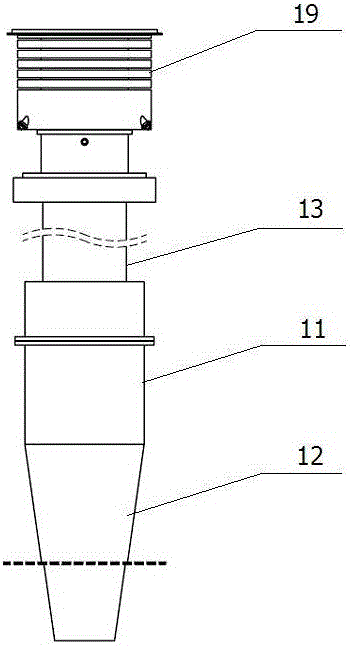

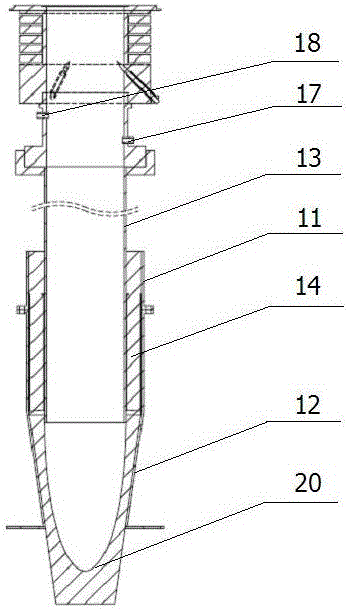

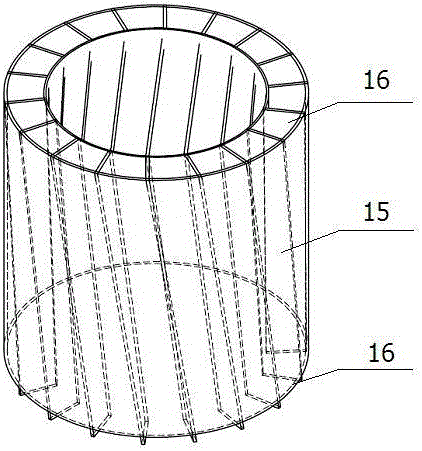

[0029] Such as figure 1 , figure 2 As shown in Fig. 1 , a coupling system between an accelerator and a windowless spallation target interface includes an inlet stagnation swirling section, a conical manifold and a pressurized proton beam incident tube. The fluid channel is injected with metal liquid in the inlet stagnation swirl section, and the metal liquid forms a free liquid surface in the fluid channel. The upper part of the free liquid surface in the fluid channel has a pressurized proton beam incident tube, and the pressurized proton beam incident tube passes through the plasma The body air pressure differential device is connected with the vacuum beam tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com