Grout sprinkling device and grout sprinkling method on fully mechanized mining face of thick seam

A technology for fully mechanized mining face and thick coal seam, which is applied in safety devices, mining equipment, earthwork drilling, etc. Reduce workload, scientific effect of spraying method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The slurry spraying device of the fully mechanized mining face in thick coal seam includes three slurry spraying units, each slurry spraying unit includes a slurry delivery pipe and a slurry spraying pipe, the diameter of the slurry spraying pipe is smaller than that of the slurry delivery pipe, and the larger The diameter of the grouting pipe can ensure that the grouting material in each grouting pipe meets the needs of the spraying flow rate; the grouting pipe and the grouting pipe are connected by a different-diameter tee, and the diameters of the two pipes in the different-diameter tee are equal to the size of the grouting pipe , the other pipe diameter is equal to the diameter of the spraying pipe; a control switch is provided at the connection between the spraying pipe and the three-way valve, which is used to control the opening of the spraying pipe; the feeding pipes of two adjacent spraying units pass through different diameters Three links in series. The grout...

Embodiment 2

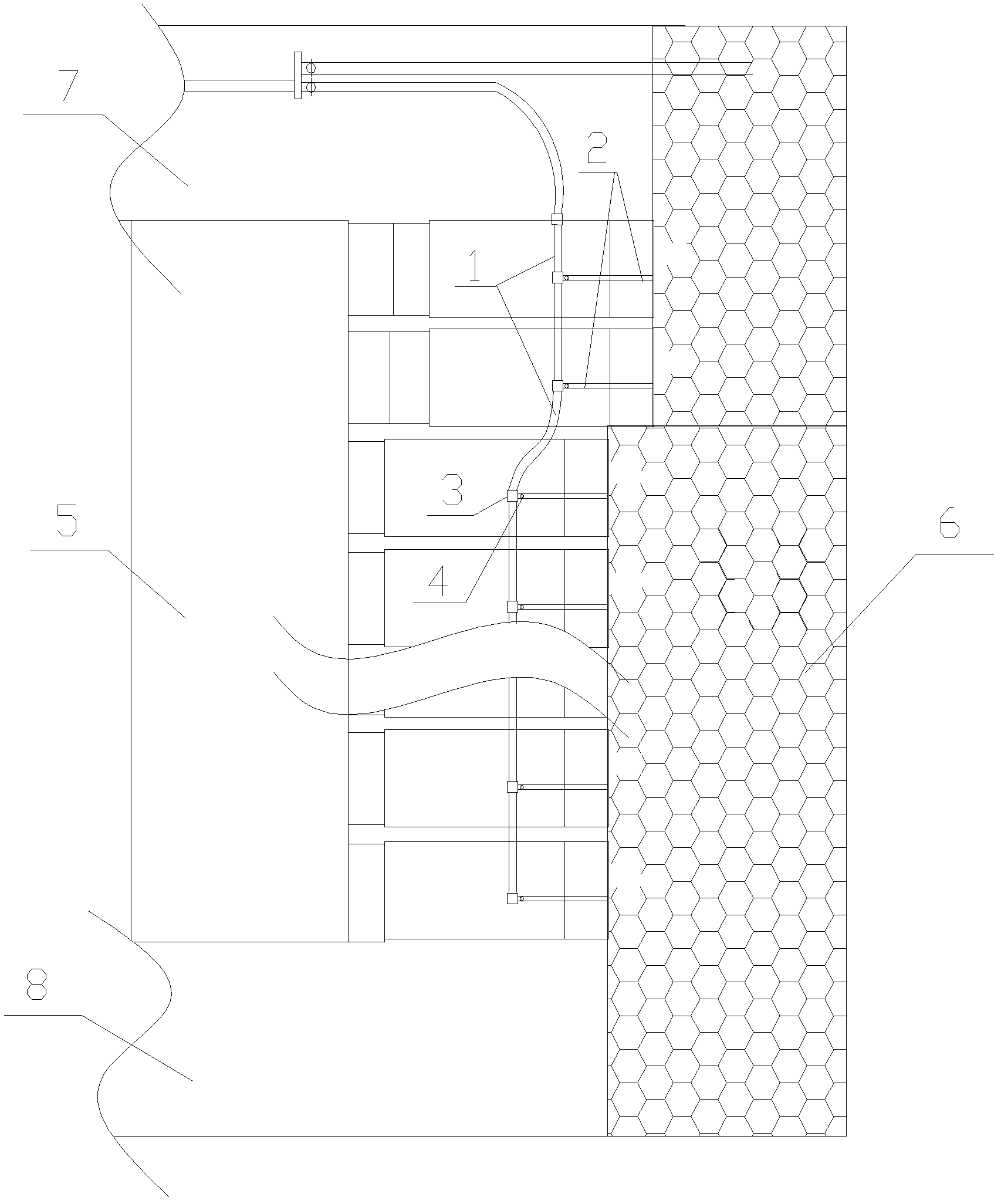

[0037] figure 1 It is a schematic structural diagram of a slurry spraying device for a fully mechanized mining face in a thick coal seam provided by Embodiment 2 of the present invention.

[0038] A slurry spraying device for a fully mechanized mining face in a thick coal seam includes a plurality of N slurry spraying units (N≥6), and each slurry spraying unit includes a slurry feeding pipe 1 and a slurry spraying pipe 2, and the diameter of the slurry spraying pipe 2 is less than The diameter of the slurry delivery pipe 1 is a high-pressure rubber hose with a diameter of Φ51mm and a length of 2.5m. Spraying pipe 2 is: Φ25mm, long 1.6m high-pressure hose. The slurry feeding pipe 1 and the slurry spraying pipe 2 are connected by the reducing tee 3. The three pipe diameters of the reducing tee 3 are Φ51mm, Φ51mm and Φ25mm respectively. Switch 4, the control switch 4 is a shut-off valve or other control components that can realize pipeline closing and opening. The slurry feedi...

Embodiment 3

[0042] This embodiment discloses a slurry spraying method for a fully mechanized mining face in a thick coal seam, which includes the following steps:

[0043] A slurry spraying pipe (Φ25mm×1.6m short high-pressure hose) with a control switch (Φ25mm cut-off valve) is laid in parallel between the coal mining face frame and the direction from the coal side to the goaf. The control switch is used to control the slurry spraying pipe spraying operation;

[0044]The side of the slurry pipeline close to the coal side is connected by a slurry delivery pipe (Φ51mm×2.5m high-pressure rubber hose), and the slurry delivery tube is connected to the slurry delivery tube through a Φ51mm variable Φ25mm tee with a different diameter, and the tee with a different diameter is fixed by a U-shaped clip The tail of the support frame is specifically fixed on the rear column of the support; the grout delivery pipe closest to the upwind lane is connected to the 4-inch grout pipeline, and the grout pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com