Package structure and manufacturing method for the same

A packaging structure and manufacturing method technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of shrinking packaging volume, expanding spacing, internal damage of chips and substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

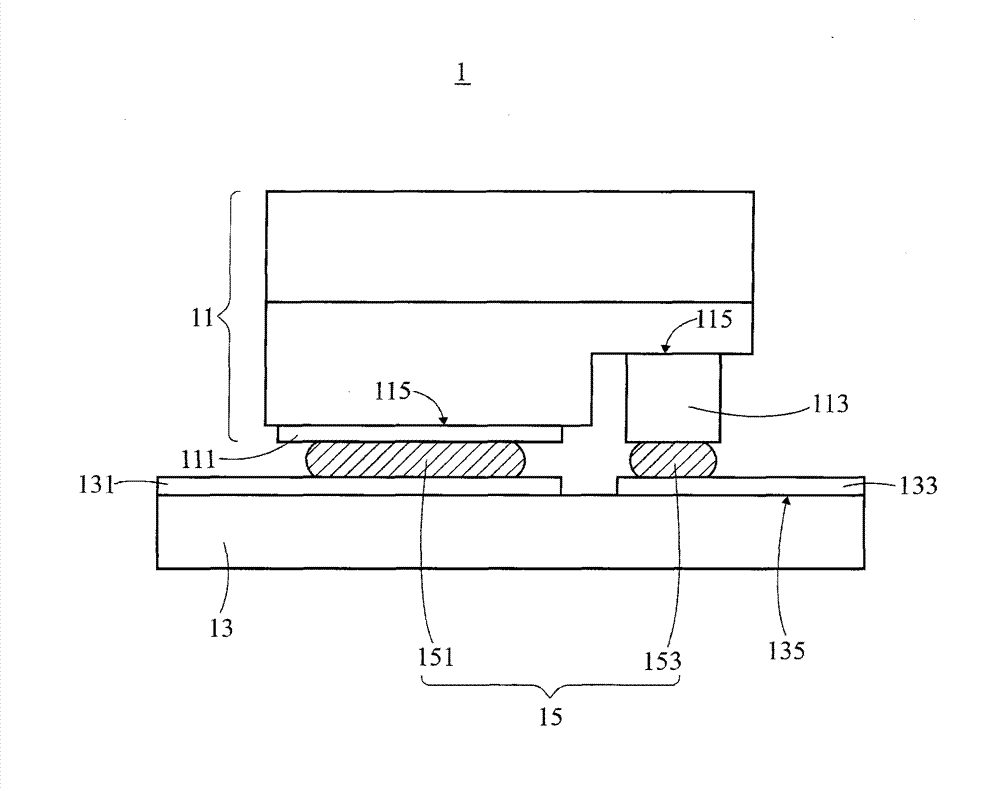

[0012] The content of the present invention will be explained through the embodiments below. The present invention relates to a packaging structure and a manufacturing method thereof. It should be noted that in the following examples and accompanying drawings, the description of the implementation is only for the purpose of explaining the present invention, rather than directly limiting the present invention. Meanwhile, the following examples and accompanying drawings are not related to the present invention. All directly related elements are omitted and not shown; and the dimensional relationship among the elements in the drawings is only for easy understanding, and is not intended to limit the actual scale.

[0013] see figure 1 , which is a schematic diagram of a preferred embodiment of the packaging structure 1 of the present invention. The packaging structure 1 includes a chip 11 , a substrate 13 and an adhesive layer 15 , and the technical content of each component will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com