Fuel assembly of light-water reactor

A fuel assembly and reactor technology, applied in the direction of reactor fuel elements, reactors, greenhouse gas reduction, etc., can solve the problems of energy loss, deterioration of heat transfer, etc., achieve the effects of reducing leakage, ensuring economy, and enhancing fluid heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

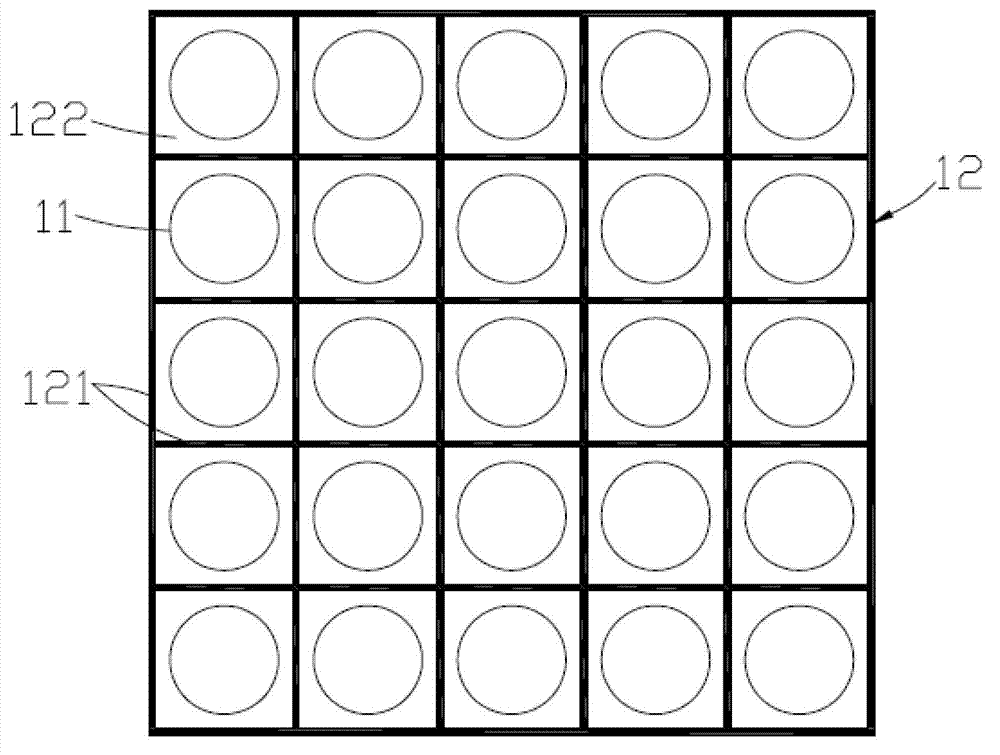

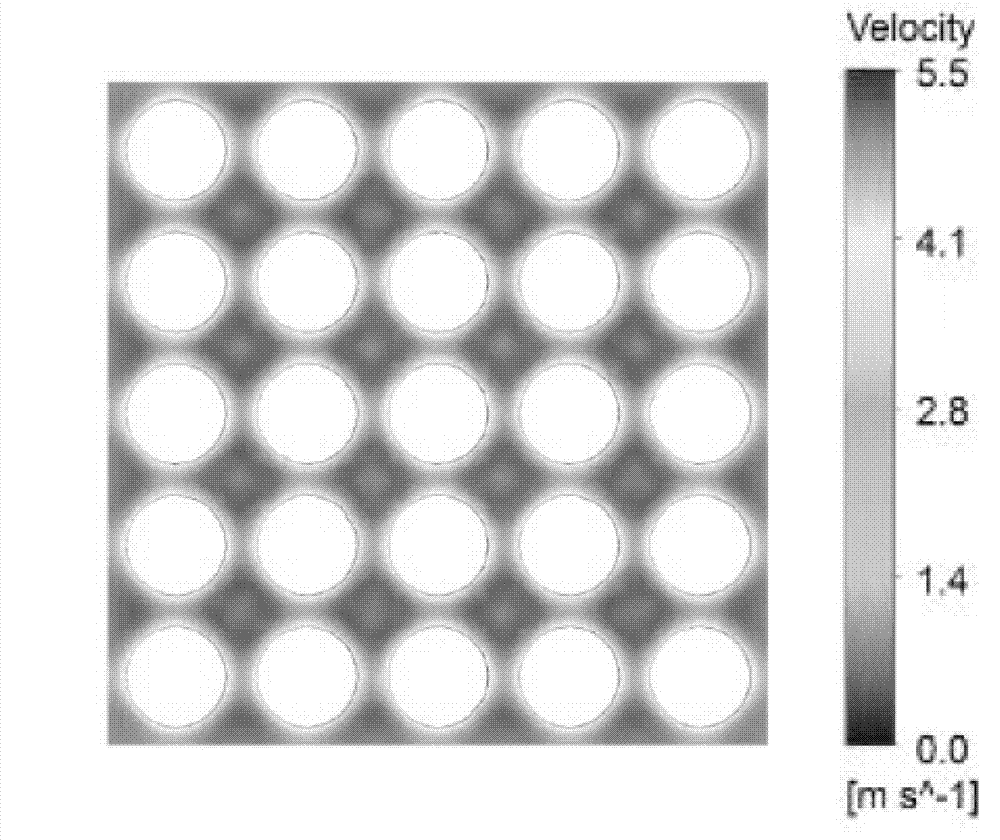

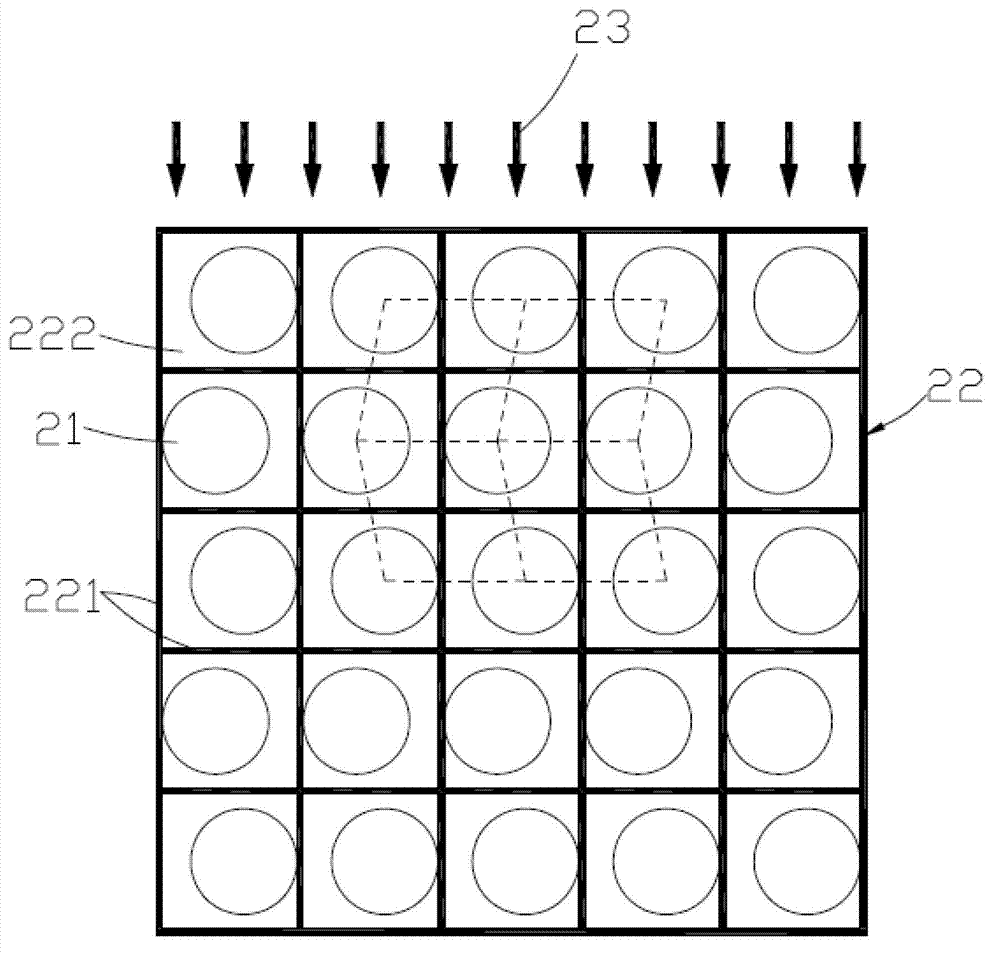

[0027] The fuel assembly of the light water reactor of the present invention includes several fuel rods and a grid, the grid is divided into several cells arranged in a rectangular array, and the fuel rods are respectively inserted into the corresponding cells and arranged In several rows and in several columns, it is characterized in that at least some of the fuel rods in the several fuel rods deviate from the center of the corresponding cell, so that there are few fuel rods in some rows between the centers of two adjacent fuel rods. The distance between them is greater than the distance between the centers of the two cells corresponding to the two adjacent fuel rods. After the fuel rods are set eccentrically, the rod spacing between two adjacent fuel rods in the same row can be increased, and the fuel rods tend to fork. Work surplus. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com