Manufacturing method for integration anti-counterfeit label

A technology of an anti-counterfeiting label and a manufacturing method, which is applied to the manufacturing field of an integrated anti-counterfeiting label, can solve the problems of increased production cost, low production efficiency, cumbersome and complicated production process, etc., and achieves saving production cost, reducing energy consumption and good anti-counterfeiting effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

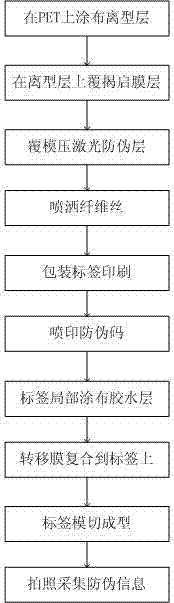

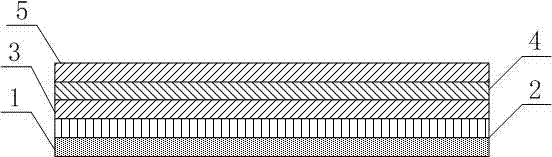

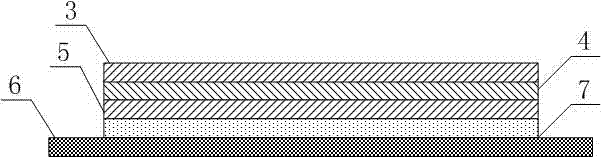

[0025] Such as Figure 1 to Figure 3 As shown, a production process of an integrated anti-counterfeit label that directly uses a part of the outer packaging film of a product as the base film of the anti-counterfeit label includes the following steps: coating a release layer 2 on a polyethylene terephthalate plastic layer 1 (PET) Cover the release layer 2 with a revealing film layer 3; cover the molded laser anti-counterfeiting layer 4 on the peeling film layer 3; randomly spray fiber filaments on the molded laser anti-counterfeiting layer 4 to form a fiber layer 5 Thereby make anti-counterfeit transfer film; Print the required information and patterns of the product on the product packaging label 6; Print the anti-counterfeit code on the label 6 printed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com