Variable water head sectional permeation coefficient measuring equipment and measuring method

A technology of permeability coefficient and measuring equipment, which is used in measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc. Complex and changeable problems, to achieve the effect of short measurement time, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

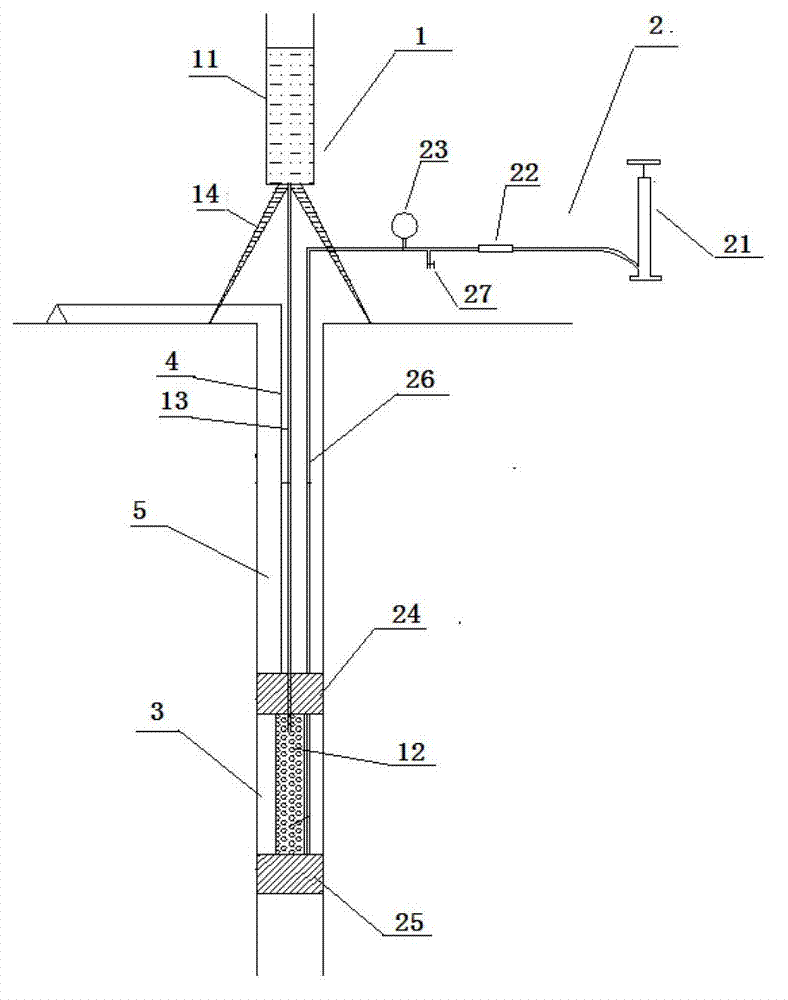

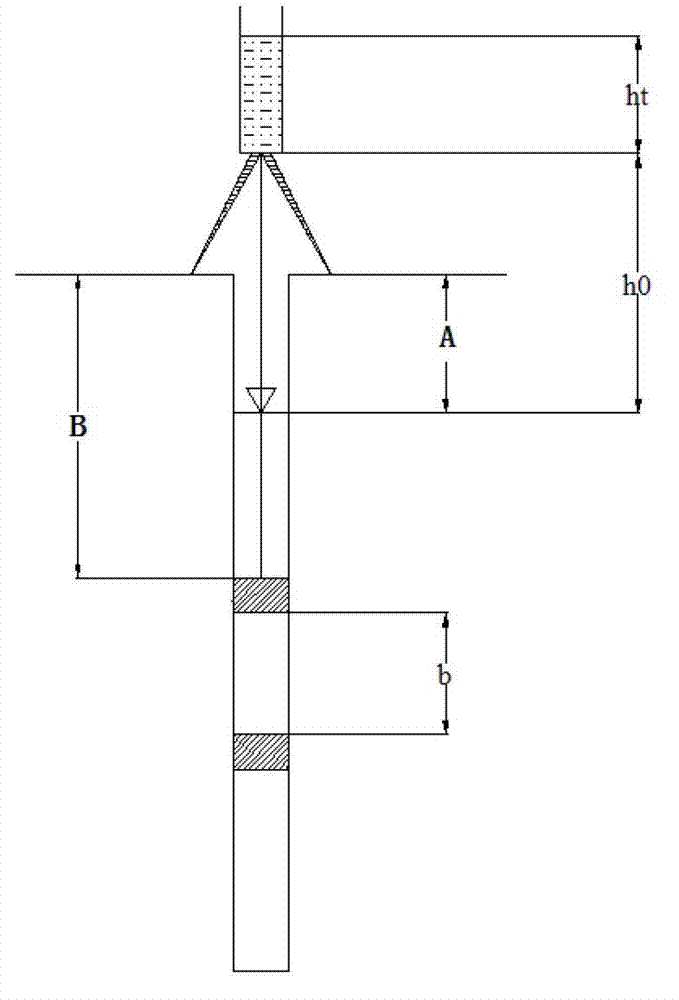

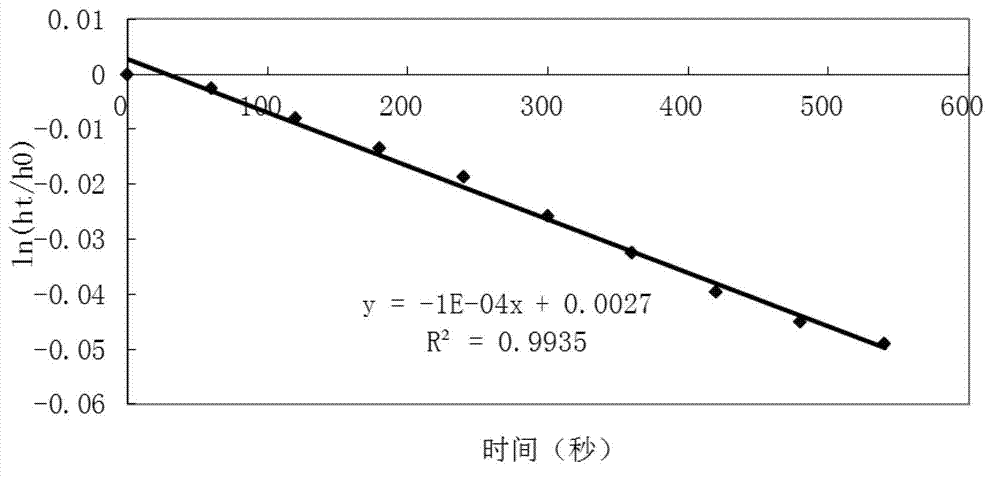

[0023] Variable head segmental permeability coefficient measurement equipment, see figure 1 , including a droplet head micro-water test device 1, a double embolism plugging device 2 and a probe 3; the micro-water test device includes a measuring cylinder 11 connected by an aqueduct 13 and a leaking flower tube 12, the lower part of the leaking flower tube 12 is water-proof, and the measuring cylinder 11 is also provided with a tripod 14 at the bottom; the double embolism occlusion device includes a high-pressure gas cylinder 21, a check valve 22, a pressure gauge 23, a first embolus 24 and a second embolus 25 connected sequentially through an airway 26 from top to bottom, An air valve 27 is also provided between the one-way valve 22 and the pressure gauge 23; the first plug 24, the leaking flower tube 12 and the second plug 25 are sequentially arranged in the probe 3 from top to bottom.

[0024] Both the first plug 24 and the second plug 25 are made of tire inner bladders; opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com