Smoke insulation and heat insulation fresh air system capable of realizing kitchen air conditioner environment

A fresh air system and air-conditioning technology, applied in household heating, household heating, heating methods, etc., can solve the problems of exhaust gas and oily fume, high temperature in the kitchen, damage to kitchen facilities, electrical appliances, etc., so as to benefit human health, Overcome the effect of air diffusion and keep the air fresh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, describe in further detail:

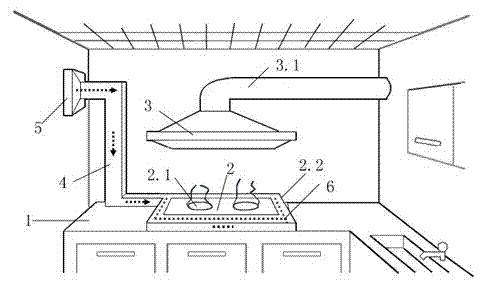

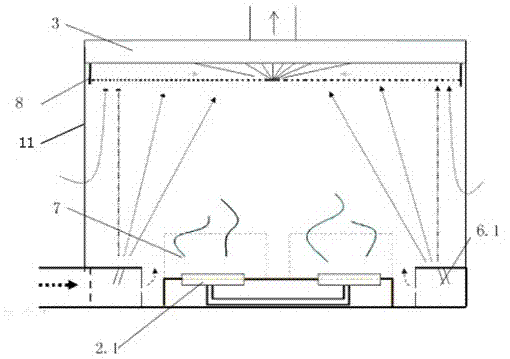

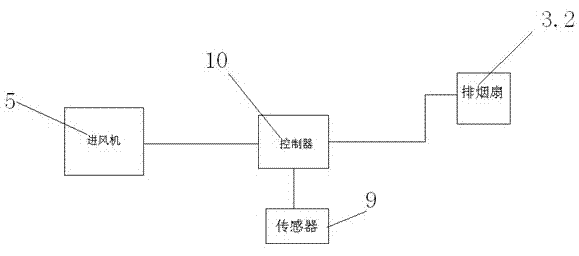

[0026] Such as figure 1 Shown is a structural schematic diagram of the present invention, the system includes a cooker 1, a cooker 2 and a range hood 3, the cooker 2 is placed on the cooker 1, and the range hood 3 is installed on the wall vertically above the cooker 2, in order to To achieve the purpose of external circulation, an air curtain generator is installed on the cooktop. The air curtain generator is formed by connecting the air intake pipe 4 and the left side of the frame-shaped casing 2.2. The inner cavity of the frame-shaped casing forms a gas channel. A diversion groove 6.1 is provided on the panel of the casing 2.2, and an ejector 6 is arranged in the diversion groove 6.1. The jet device 6 is made of two strip plates 6.2 and several jet deflectors 6.3, and the outside of the strip plates 6.2 is provided with a windshield mounting groove 6.4. The jet deflectors 6.3 are equidist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com